Welding thread!!!!

#782

Well, kind of. There is self shielded wire that 99% of you guys would call "flux core" and then there is dual shielded wire that has a fluxing agent but, requires the use of a shielding gas as well. The wire that comes in cheap starter kit welders is self shielded wire. Typically, dual shielded wire is used when welding thick (3/4"+) material. The reason for this is that, although the standard solid wire can weld thicker material, you must be in spray transfer to do so and you cannot weld out of position in spray. If you do not spray transfer with solid mig at those thicknesses, you will get cold lap. Generally, dual shielded wire is sold in thicker sizes (.045+) because of the nature of it's uses. The flux core wire that is your box store welders does not need gas, nor will you benefit from it. Actually, you will create more fumes than necessary and have a colder weld. Hope that clears it up for everyone.

#783

CF Veteran

Join Date: Jul 2011

Location: Warren, Pa

Posts: 2,164

Likes: 0

Received 1 Like

on

1 Post

Year: 97

Model: Cherokee

Engine: 4.0L

I love .030 solid with a really narrow tip on the gun for 90% of what I do on my Cherokee. The majority of the stuff I run at work is Hyundai .045 DS with straight CO2. Run it up to about 320 amps and you can weld anything as long as it's thick as ****

#784

#786

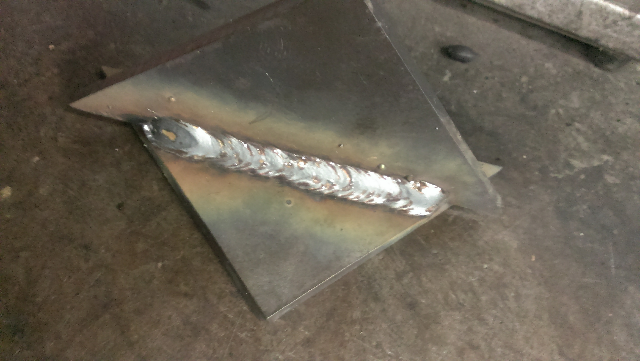

thanks yeah I wasn't trying to overlap really just side by side then I realized it didn't make sense to not overlap on a Tee joint

#790

Well, kind of. There is self shielded wire that 99% of you guys would call "flux core" and then there is dual shielded wire that has a fluxing agent but, requires the use of a shielding gas as well. The wire that comes in cheap starter kit welders is self shielded wire. Typically, dual shielded wire is used when welding thick (3/4"+) material. The reason for this is that, although the standard solid wire can weld thicker material, you must be in spray transfer to do so and you cannot weld out of position in spray. If you do not spray transfer with solid mig at those thicknesses, you will get cold lap. Generally, dual shielded wire is sold in thicker sizes (.045+) because of the nature of it's uses. The flux core wire that is your box store welders does not need gas, nor will you benefit from it. Actually, you will create more fumes than necessary and have a colder weld. Hope that clears it up for everyone.

#791

::CF Administrator::

Some safety chain posts I cooked up the other day at work. Took about 4 hours to drill the plate for concrete anchors, cut the posts, weld em up, cut some chain links in half to clip onto, and weld the halves to the top of the posts. Simple job, but I think they turned out nice. Painted and installed them the next day...no pics of that yet, waiting on the chain...

#792

Seasoned Member

Join Date: Jan 2011

Location: Central Jersey

Posts: 437

Likes: 0

Received 0 Likes

on

0 Posts

Year: 91

Model: Cherokee

Engine: 4.0 I6 H.O.

Some safety chain posts I cooked up the other day at work. Took about 4 hours to drill the plate for concrete anchors, cut the posts, weld em up, cut some chain links in half to clip onto, and weld the halves to the top of the posts. Simple job, but I think they turned out nice. Painted and installed them the next day...no pics of that yet, waiting on the chain...

Attachment 262852

Attachment 262853

Attachment 262852

Attachment 262853

#793

Member

Join Date: Oct 2014

Location: San Diego, CA

Posts: 187

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Since the OP approved asking for tips, here I go with asking: I have the opportunity to pick up a Hobart Handler 135 on a trade with a local guy. I'm going to check it out tomorrow but he says it has very little time on it because he used it for side jobs doing gate and handrail repair. Based on what I've read, they have problems with the controllers and are only good for 3/16 and thinner metal. Would you guys recommend this unit for a first welder? My immediate jobs are welding spring perches and shock tabs for an 8.8 swap and rewelding my rear fender pinch seams.

#794

CF Veteran

Join Date: Jul 2011

Location: Warren, Pa

Posts: 2,164

Likes: 0

Received 1 Like

on

1 Post

Year: 97

Model: Cherokee

Engine: 4.0L

Since the OP approved asking for tips, here I go with asking: I have the opportunity to pick up a Hobart Handler 135 on a trade with a local guy. I'm going to check it out tomorrow but he says it has very little time on it because he used it for side jobs doing gate and handrail repair. Based on what I've read, they have problems with the controllers and are only good for 3/16 and thinner metal. Would you guys recommend this unit for a first welder? My immediate jobs are welding spring perches and shock tabs for an 8.8 swap and rewelding my rear fender pinch seams.