Welding thread!!!!

#1606

CF Veteran

Join Date: Mar 2012

Location: Quebec

Posts: 1,024

Likes: 0

Received 1 Like

on

1 Post

Year: 1996

Model: Cherokee

Engine: 4.0L

so I got myself the welder I previously posted on here, it's a lincoln 180hd MIG & flux core. haven't gotten around to try it out yet, but I was wondering if I need gas or if I can still manage to weld without it? My goal is to replace my rockers with 2x6. should I get a tank or it's not necessary?

#1607

CF Veteran

Join Date: Jan 2013

Location: west chester, pa

Posts: 19,216

Likes: 0

Received 39 Likes

on

35 Posts

Year: 1999

Engine: 4.0

so I got myself the welder I previously posted on here, it's a lincoln 180hd MIG & flux core. haven't gotten around to try it out yet, but I was wondering if I need gas or if I can still manage to weld without it? My goal is to replace my rockers with 2x6. should I get a tank or it's not necessary?

#1608

CF Veteran

Join Date: Mar 2012

Location: Quebec

Posts: 1,024

Likes: 0

Received 1 Like

on

1 Post

Year: 1996

Model: Cherokee

Engine: 4.0L

yeah by reading a bunch I figured that's what it was, I wanted to make sure. Here's from their site :

So basically by selecting the flux cored setting and using the appropriate wire (I'm guessing?) it should do the job? I have a lot of practice ahead of me, but at least if I can do it without needing gas, that saves some money. thanks

Simple two **** control makes it easy to tackle thin steel, stainless or aluminum sheet metal with MIG or thicker steel with flux-cored welding.

#1609

::CF Administrator::

yeah by reading a bunch I figured that's what it was, I wanted to make sure. Here's from their site :

So basically by selecting the flux cored setting and using the appropriate wire (I'm guessing?) it should do the job? I have a lot of practice ahead of me, but at least if I can do it without needing gas, that saves some money. thanks

So basically by selecting the flux cored setting and using the appropriate wire (I'm guessing?) it should do the job? I have a lot of practice ahead of me, but at least if I can do it without needing gas, that saves some money. thanks

Word of warning...flux core is messy, not out of control, but different than MIG...FC works great for welding things if you are in outdoor or windy conditions, but it does spatter and outgas. You will need a chipping hammer for spatter, and a wire brush to clean/inspect your welds.

I know spending extra money is not desireable, but I highly suggest getting a bottle. Biggest you can afford. Much cleaner, less work.

#1610

CF Veteran

Join Date: Jan 2013

Location: west chester, pa

Posts: 19,216

Likes: 0

Received 39 Likes

on

35 Posts

Year: 1999

Engine: 4.0

Before you do ANYTHING, practice, practice, practice...with either of your choosing. Word of warning...flux core is messy, not out of control, but different than MIG...FC works great for welding things if you are in outdoor or windy conditions, but it does spatter and outgas. You will need a chipping hammer for spatter, and a wire brush to clean/inspect your welds. I know spending extra money is not desireable, but I highly suggest getting a bottle. Biggest you can afford. Much cleaner, less work.

#1611

CF Veteran

Join Date: Mar 2012

Location: Quebec

Posts: 1,024

Likes: 0

Received 1 Like

on

1 Post

Year: 1996

Model: Cherokee

Engine: 4.0L

yes about the practice I'm aware. I want to do the best job I can and I'm not the type to just go right at it, I'll make sure I know what I'm doing way before I attempt it.

and from the videos I've seen, flux core does seem a lot more messy. In case I don't get gas, can I use a large sheet of metal to protect the body panels while I weld? Being outside is not a problem, that's what my setup allows me to do, but what I'd be concerned is the bottom of my doors.

and from the videos I've seen, flux core does seem a lot more messy. In case I don't get gas, can I use a large sheet of metal to protect the body panels while I weld? Being outside is not a problem, that's what my setup allows me to do, but what I'd be concerned is the bottom of my doors.

#1612

Newbie

Join Date: Oct 2013

Location: Near Billings Montana

Posts: 25

Likes: 0

Received 0 Likes

on

0 Posts

Year: 95

Model: Grand Cherokee

I would also definately recommend getting a bottle. I'd also recommend getting dual shield wire if at all possible.

Gasless wire is messy and, in my experience, takes a lot of practice to get good with.

Dual Shield welds easier, cleans up MUCH easier, and produces a much better and prettier weld.

The only downside is the difficulty using it outside, but that's what tarps and bungy cords are for.

Good luck, hope this helps!

Ron

Gasless wire is messy and, in my experience, takes a lot of practice to get good with.

Dual Shield welds easier, cleans up MUCH easier, and produces a much better and prettier weld.

The only downside is the difficulty using it outside, but that's what tarps and bungy cords are for.

Good luck, hope this helps!

Ron

Last edited by MtPockets; 03-17-2016 at 08:08 AM.

#1613

CF Veteran

Join Date: Mar 2012

Location: Quebec

Posts: 1,024

Likes: 0

Received 1 Like

on

1 Post

Year: 1996

Model: Cherokee

Engine: 4.0L

thanks ron. the most "indoor" I can get and also where I planned to do most of my practice and work, is in a barn. would gas be fine in this environment? the roof is water tight, but it's not heated or anything fancy like that.

of course when I'm not using it I would store the welder and everything else inside the house, but I can't work inside there.

I'm all for the less messy and easiest way possible, so if that involves getting a bottle, I'll shop around different welding shops. To get an idea, what prices am I looking at for the bottle itself? Can I get something decent for 150-200? For all the gear and supply, not counting getting a bottle filled, I have a budget of around 350.

of course when I'm not using it I would store the welder and everything else inside the house, but I can't work inside there.

I'm all for the less messy and easiest way possible, so if that involves getting a bottle, I'll shop around different welding shops. To get an idea, what prices am I looking at for the bottle itself? Can I get something decent for 150-200? For all the gear and supply, not counting getting a bottle filled, I have a budget of around 350.

Last edited by Cane; 03-17-2016 at 08:50 AM.

#1614

CF Veteran

Join Date: Jan 2013

Location: west chester, pa

Posts: 19,216

Likes: 0

Received 39 Likes

on

35 Posts

Year: 1999

Engine: 4.0

I would also definately recommend getting a bottle. I'd also recommend getting dual shield wire if at all possible. Gasless wire is messy and, in my experience, takes a lot of practice to get good with. Dual Shield welds easier, cleans up MUCH easier, and produces a much better and prettier weld. The only downside is the difficulty using it outside, but that's what tarps and bungy cords are for. Good luck, hope this helps! Ron

#1615

::CF Administrator::

thanks ron. the most "indoor" I can get and also where I planned to do most of my practice and work, is in a barn. would gas be fine in this environment? the roof is water tight, but it's not heated or anything fancy like that.

of course when I'm not using it I would store the welder and everything else inside the house, but I can't work inside there.

I'm all for the less messy and easiest way possible, so if that involves getting a bottle, I'll shop around different welding shops. To get an idea, what prices am I looking at for the bottle itself? Can I get something decent for 150-200? For all the gear and supply, not counting getting a bottle filled, I have a budget of around 350.

of course when I'm not using it I would store the welder and everything else inside the house, but I can't work inside there.

I'm all for the less messy and easiest way possible, so if that involves getting a bottle, I'll shop around different welding shops. To get an idea, what prices am I looking at for the bottle itself? Can I get something decent for 150-200? For all the gear and supply, not counting getting a bottle filled, I have a budget of around 350.

Bottle prices...shop around, see what the local places charge. The bottles are kinda expensive, but you can rent or lease one, and refills are relatively inexpensive.

#1617

::CF Administrator::

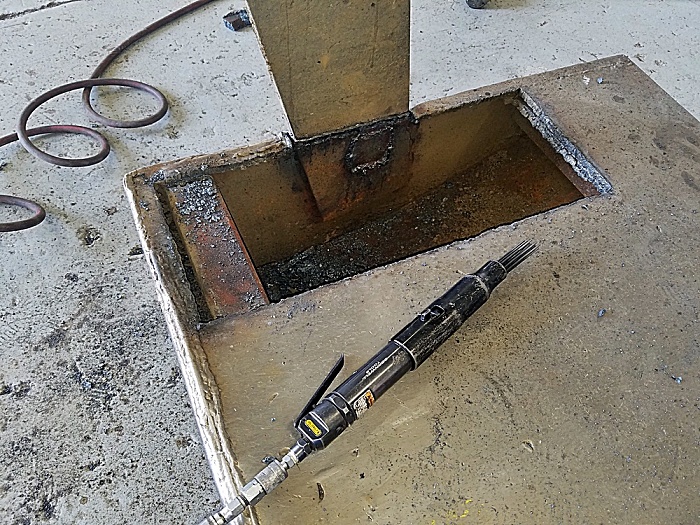

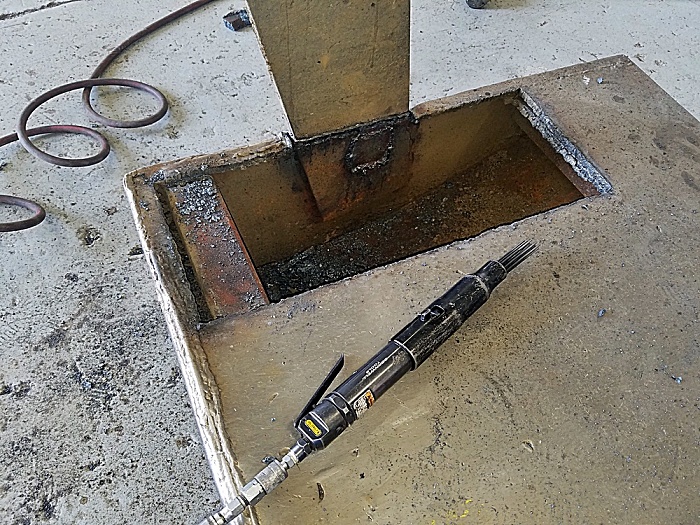

So finally finished the packer/hopper repair...then another truck came in with a broken packer...swapped out the broken packer with the one I just finished to get them back on the road...stupid driver, knew something was stuck in there, but kept trying to compact it anyways...we never did find out what it was, as he dumped his load before bringing the truck over.

The truck and packer we were working...

The truck that came in...

Thing that sucks? I recently repaired that packer, too. All that work toasted because of an idiot driver.

The truck and packer we were working...

The truck that came in...

Thing that sucks? I recently repaired that packer, too. All that work toasted because of an idiot driver.

#1618

::CF Administrator::

So I've been working on that packer...however I keep getting interrupted with dailies and other crap...so not making the progress I would like...could've had this thing gone this week, but you know how that goes, LOL

These pics took place over the last week and a half or so...you'll see some more pics of the damage, and the stages it took to get to where I am now: Putting it back together. Used the oxy torches to cut out the bad steel, and as I got into each deeper layer, more problems presented themselves. The sleeve on the main shaft was cracked in half internally...so had to take it all the way down to the main shaft, and completely rebuild the left side of the packer.

After I got the fish plate off...

Opened up the packer to get the broken arm out...

Yeah, it came out in sections, LOL

After I got down to the main shaft...ground down and "polished" with a flap wheel...

New sleeve...

Check fitting the new sleeve...

Rest of the broken arm scarfed out...

New packer cylinder arm, tacked together...

New main arm, waiting to go in...

Got the sleeve tacked in, and before I could start laying beads, got pulled to replace a tarp on a transfer trailer...these drivers are butchers, LOL

These pics took place over the last week and a half or so...you'll see some more pics of the damage, and the stages it took to get to where I am now: Putting it back together. Used the oxy torches to cut out the bad steel, and as I got into each deeper layer, more problems presented themselves. The sleeve on the main shaft was cracked in half internally...so had to take it all the way down to the main shaft, and completely rebuild the left side of the packer.

After I got the fish plate off...

Opened up the packer to get the broken arm out...

Yeah, it came out in sections, LOL

After I got down to the main shaft...ground down and "polished" with a flap wheel...

New sleeve...

Check fitting the new sleeve...

Rest of the broken arm scarfed out...

New packer cylinder arm, tacked together...

New main arm, waiting to go in...

Got the sleeve tacked in, and before I could start laying beads, got pulled to replace a tarp on a transfer trailer...these drivers are butchers, LOL

#1619

Newbie

Join Date: Oct 2013

Location: Near Billings Montana

Posts: 25

Likes: 0

Received 0 Likes

on

0 Posts

Year: 95

Model: Grand Cherokee

I don't want you to take this wrong, as it appears you do very good work and I understand why you like to show it off, but could you please cut back on the work stories?

I don't mind seeing an occasional 'look what I did', but for quite some time now we've gotten an overload on the repair of garbage packers.

Like I said, it looks like you do some fine work so your input is appreciated when someone needs help.

But this is a JEEP site, not a Garbage Truck site.

Thanks for understanding.

I don't mind seeing an occasional 'look what I did', but for quite some time now we've gotten an overload on the repair of garbage packers.

Like I said, it looks like you do some fine work so your input is appreciated when someone needs help.

But this is a JEEP site, not a Garbage Truck site.

Thanks for understanding.

#1620

CF Veteran

I don't want you to take this wrong, as it appears you do very good work and I understand why you like to show it off, but could you please cut back on the work stories?

I don't mind seeing an occasional 'look what I did', but for quite some time now we've gotten an overload on the repair of garbage packers.

Like I said, it looks like you do some fine work so your input is appreciated when someone needs help.

But this is a JEEP site, not a Garbage Truck site.

Thanks for understanding.

I don't mind seeing an occasional 'look what I did', but for quite some time now we've gotten an overload on the repair of garbage packers.

Like I said, it looks like you do some fine work so your input is appreciated when someone needs help.

But this is a JEEP site, not a Garbage Truck site.

Thanks for understanding.

This isn't a Jeep specific welding thread. If you want one, you should go start one.