Noob weld cart build.

#1

CF Veteran

Thread Starter

Join Date: Dec 2012

Location: York, PA

Posts: 4,169

Likes: 0

Received 6 Likes

on

6 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

Hey Guys!

So, I know this isnít really an XJ-specific project but it still seemed to fit the guidelines for the Fab section. I wouldn't even be starting this project if it wasn't for my XJ in the first place, so here we go! I recently purchased my first MIG setup, and now Iím working on my very first projectóa multi-purpose welding cart!

A little background, the whole reason I purchased this welder is to fix the rust on my XJ. I also plan on doing 2x6 rocker sliders since my rockers are rusted out. I welded in shop class in high school about 8 years ago and figured this will be great practice for me to get up to speed before I actually start welding on the Jeep.

So Iíve had a lot of ideas about how to do this thing, and so far here is the current culmination of features:

So, also keep in mind that I will be basically building this thing with only the welder, an angle grinder, and a drill. I don't even have a damn workbench! I also have very little as far as a plan goes and Iím basically winging it as I go. I started working on this yesterday, now for the goodies..

I don't even have a damn workbench! I also have very little as far as a plan goes and Iím basically winging it as I go. I started working on this yesterday, now for the goodies..

Hereís what Iím starting with after a trip to Tractor SupplyÖThis is enough to begin the base of the cart. 1x1 steel, some flat iron, and I forget the size of the smaller bar that Iím going to use as a cross-grate type deal for support.

After some measuring and comparing to the box the welder came in, and mocking up some stuff on the garage floor with the welder itself, I came up with 28Ēx14.5Ē for the base. Getting ready for the first cut! My workbench is merely a 2x4 and a C-clamp

First cut!

I started playing around with the various pieces I have to get a feel of how Iím going to attach the wheels while keeping it level as possible. I havenít decided yet if Iím going to run the rear wheels right through the 1x1, or weld a sleeve onto the bottom of it yet. Either seems like it would work OK at this point. The rear and front wheels both have 3Ē from the ďaxleĒ or part that connects to the cart, and the point of contact with the floor.

The front wheels are 2x2Ē, so I will end up welding a 1Ē corner piece on the inside of the frame to support the wheels.

More mock-upÖ

Now that the cuts are done and mockup complete, time for the fun partóstart welding it together!

Overall, I donít think I did *too* bad for having a shaky hand. I have a few more to do yet but so far it is very sturdy with these welds. I used the chart on the inside of the welder and it seems to be quite accurate. Arc voltage set at ďFĒ, wire speed at 5.5. Critiques, tips, etc. welcome.

Thatís all for now, Iíll be back on this later today!

So, I know this isnít really an XJ-specific project but it still seemed to fit the guidelines for the Fab section. I wouldn't even be starting this project if it wasn't for my XJ in the first place, so here we go! I recently purchased my first MIG setup, and now Iím working on my very first projectóa multi-purpose welding cart!

A little background, the whole reason I purchased this welder is to fix the rust on my XJ. I also plan on doing 2x6 rocker sliders since my rockers are rusted out. I welded in shop class in high school about 8 years ago and figured this will be great practice for me to get up to speed before I actually start welding on the Jeep.

So Iíve had a lot of ideas about how to do this thing, and so far here is the current culmination of features:

- Red and Rustoleum Hammered finish

- Fire extinguisher mount

- Dual duplex power outlet panel on the front + dedicated outlet on the rear for welder (Logistics of that to be figured out yet)

- Diamond plate outlet covers w/ red outlets for visibility

- Mounts for other tools such as angle grinder, drill, etc.

- Possibly a drawer for misc. storage

- Ball-bearing pushmower wheels and locking front swivel wheels

So, also keep in mind that I will be basically building this thing with only the welder, an angle grinder, and a drill.

I don't even have a damn workbench! I also have very little as far as a plan goes and Iím basically winging it as I go. I started working on this yesterday, now for the goodies..

I don't even have a damn workbench! I also have very little as far as a plan goes and Iím basically winging it as I go. I started working on this yesterday, now for the goodies..Hereís what Iím starting with after a trip to Tractor SupplyÖThis is enough to begin the base of the cart. 1x1 steel, some flat iron, and I forget the size of the smaller bar that Iím going to use as a cross-grate type deal for support.

After some measuring and comparing to the box the welder came in, and mocking up some stuff on the garage floor with the welder itself, I came up with 28Ēx14.5Ē for the base. Getting ready for the first cut! My workbench is merely a 2x4 and a C-clamp

First cut!

I started playing around with the various pieces I have to get a feel of how Iím going to attach the wheels while keeping it level as possible. I havenít decided yet if Iím going to run the rear wheels right through the 1x1, or weld a sleeve onto the bottom of it yet. Either seems like it would work OK at this point. The rear and front wheels both have 3Ē from the ďaxleĒ or part that connects to the cart, and the point of contact with the floor.

The front wheels are 2x2Ē, so I will end up welding a 1Ē corner piece on the inside of the frame to support the wheels.

More mock-upÖ

Now that the cuts are done and mockup complete, time for the fun partóstart welding it together!

Overall, I donít think I did *too* bad for having a shaky hand. I have a few more to do yet but so far it is very sturdy with these welds. I used the chart on the inside of the welder and it seems to be quite accurate. Arc voltage set at ďFĒ, wire speed at 5.5. Critiques, tips, etc. welcome.

Thatís all for now, Iíll be back on this later today!

#2

Herp Derp Jerp

Join Date: Nov 2011

Location: Parham, ON

Posts: 18,251

Likes: 0

Received 12 Likes

on

11 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L OBD-II

Cool. That one end with the wonky angle cut threw me off in the pics. Looks like fun! The cart seems very tight for just the welder and gas, where did you plan on putting a receptacle exactly?

#6

CF Veteran

Join Date: Sep 2011

Location: Frederick, MD

Posts: 10,447

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1989

Model: Cherokee

Engine: 4.0

I'd play around with the settings a little more, I'd also try slowing down a little or don't start your bead until you get a good puddle started.

Otherwise they look just like mine when I first started. Keep up the good work!

Otherwise they look just like mine when I first started. Keep up the good work!

#7

CF Veteran

Thread Starter

Join Date: Dec 2012

Location: York, PA

Posts: 4,169

Likes: 0

Received 6 Likes

on

6 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

Thanks for the compliments, everyone!

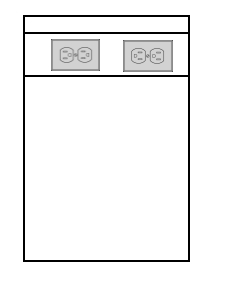

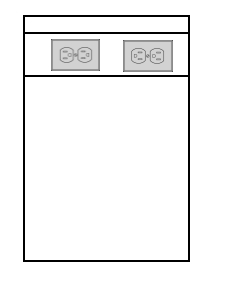

LOL, it's hard to get a straight cut with nothing but an angle grinder and a 2x4. I've given myself some breathing room for tidying up the edges..should've done that before welding it I guess!  As for the outlets, I plan on putting them on the front of the cart, like this...

As for the outlets, I plan on putting them on the front of the cart, like this...

Excuse the poor drawing. The white space above the outlet panel I put there as a placeholder for a handle.

Oh, definitely. I will cross that bridge when I get to it. I originally was going to work from the top down, but decided to start at the bottom and work my way upwards. I'll need to figure out the handle situation also.

Thanks! I'll take heed to these tips. I hadn't started a puddle first, kind of went right into a bead. Do they look too hot to you, or maybe slow the wire speed a little? They seem to have penetrated well but it's hard to tell for a noob like me.

Excuse the poor drawing. The white space above the outlet panel I put there as a placeholder for a handle.

Trending Topics

#8

CF Veteran

Join Date: Sep 2011

Location: Frederick, MD

Posts: 10,447

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1989

Model: Cherokee

Engine: 4.0

Starting the puddle is key. I like to start the puddle then go side to side. Some people prefer making circles. Try both and see what you like.

#10

::CF Administrator::

Great first project! Definitely keep us updated with pics. You gonna build a welding table/workbench as well?

#12

::CF Administrator::

#14

CF Veteran

Thread Starter

Join Date: Dec 2012

Location: York, PA

Posts: 4,169

Likes: 0

Received 6 Likes

on

6 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

Thanks for the tips everyone, definitely helps me. I know I'll have gravity against me trying to weld 2x6 rockers in on a non-lifted Jeep, underneath!

#15

CF Veteran

Join Date: Jul 2011

Location: JOCO

Posts: 4,521

Likes: 0

Received 1 Like

on

1 Post

Year: 1999

Engine: 4.0 Inline 6

Little e-whips are good too, kinda depends on what position you're welding in, keep playing with it, you'll get it...run some practice beads on any scrap material you have, and weld in flat, horizontal, vertical and overhead positions, you can't always move pieces around when working on some projects, and gravity can be a *****, LOL...Perfect makes practice...