Transfer Case / 4WD Question

#1

Newbie

Thread Starter

Join Date: Dec 2010

Posts: 24

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

Whats going on fellow Jeep lovers..? My name is Chris and I drive a 96 Cherokee Country, nothing really special, 3 inch lift, 31.5 Goodyear Wrangler M/Ts. Its basically stock. I have owned this thing for about 4 years. I havent done too much heavy wheeling with it the last 2 years because its my daily driver and I can't afford to do major repairs. Let me just say first that I love this thing. Its the toughest, most reliable vehicle I've ever owned. I love pushing my vehicles to the limit. When I get out of college, I plan on adding height, power, and metal so I can drive this thing on the moon.

Enough of that.

Here's my issue/issues. I read on some previous posts about the rattling that comes from the Tcase. I have the 231, and the chain does seem like its the problem...

1. If the chain is what is making the rattling (which is not like a baby rattle, but more like what you hear at the top of a rollercoaster before the cart is released to freefall) does it make sense that I hear LESS OR ALMOST NO rattle when in 2H?

2. I for the last few years, I haven't been able to get it in to 4L. If I put Trans and Tcase into N, then shift to 4L, then shift to D, it will stay in gear for about 5 feet before slipping out of 4L. If I try to re-engage into 4L, it grinds and talks back to me. It refuses to cooperate haha. So, could that be due to the 'stretched' chain?

3. I just changed my Tcase fluid, which was extremely low. I checked the drain plug for shavings and dug my finger around in the drain hole and still no shavings. I'm crossing my fingers, but I think that is a good indicator that my gears are ok. Am I on the right track?

I am an engine guy mostly. I built Detroit Diesel 6V53T engines in the Marine Corps, the Tcase and Diff guys were a different section than mine. So I'm not an expert mechanic by any means, but I'm good enough to understand if you have specific and complex advice. I'm new to this forum and I think I love it..

I greatly appreciate anything you guys could offer. Have a great day.

Chris

Enough of that.

Here's my issue/issues. I read on some previous posts about the rattling that comes from the Tcase. I have the 231, and the chain does seem like its the problem...

1. If the chain is what is making the rattling (which is not like a baby rattle, but more like what you hear at the top of a rollercoaster before the cart is released to freefall) does it make sense that I hear LESS OR ALMOST NO rattle when in 2H?

2. I for the last few years, I haven't been able to get it in to 4L. If I put Trans and Tcase into N, then shift to 4L, then shift to D, it will stay in gear for about 5 feet before slipping out of 4L. If I try to re-engage into 4L, it grinds and talks back to me. It refuses to cooperate haha. So, could that be due to the 'stretched' chain?

3. I just changed my Tcase fluid, which was extremely low. I checked the drain plug for shavings and dug my finger around in the drain hole and still no shavings. I'm crossing my fingers, but I think that is a good indicator that my gears are ok. Am I on the right track?

I am an engine guy mostly. I built Detroit Diesel 6V53T engines in the Marine Corps, the Tcase and Diff guys were a different section than mine. So I'm not an expert mechanic by any means, but I'm good enough to understand if you have specific and complex advice. I'm new to this forum and I think I love it..

I greatly appreciate anything you guys could offer. Have a great day.

Chris

#2

Seasoned Member

Join Date: Nov 2008

Location: Virginia

Posts: 452

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0 H.O.

I would check your linkage and make sure your linkage underneath hasnt become damaged or disconnected. If still no go, I would purchase a new t-case and put some money into it. Add a slip-yoke eliminator to it, get a HD 231 kit for it and upgrade some of the inards. Good Luck!!

#3

Newbie

Thread Starter

Join Date: Dec 2010

Posts: 24

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

Thanks for your input. I'm right in the middle of college so I'm not exactly able to spend the 1200 bucks for a new tcase w/ upgrade. I'd like to at least try to start small, like replacing the tcase chain. I don't plan on doing any heavy wheeling until I get out of college in a few years (living on the GI Bill from my service in the USMC) because I'm just barely scraping along. I know the problem is in the tcase. I'm posting on here because I DONT want to replace it hahaha!

"Two Wongs don't make a white, they make a wittle Wong."

"Two Wongs don't make a white, they make a wittle Wong."

#4

Member

Join Date: Nov 2010

Posts: 194

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1994

Model: Cherokee

Engine: 4.0

I would check your linkage and make sure your linkage underneath hasnt become damaged or disconnected. If still no go, I would purchase a new t-case and put some money into it. Add a slip-yoke eliminator to it, get a HD 231 kit for it and upgrade some of the inards. Good Luck!!

USMC, you can take the rear half of the xfercase off without removing it from the vehicle, and then you can see if your chain is stretched out and has been rubbing on the gears or the case. Or instead of taking the cover off twice, purchase a new chain about $100.00 and replace it, you worked on engine in the corp, so this chain replacement is a no brainer.

If your gears and case show minor rubbing put the new chain on and run it, also clean the magnet on the bottom of the case while your in there.

Rob

Last edited by CJ7365; 12-13-2010 at 07:31 PM.

#5

Seasoned Member

Join Date: Jun 2010

Location: Ontario Canada

Posts: 275

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

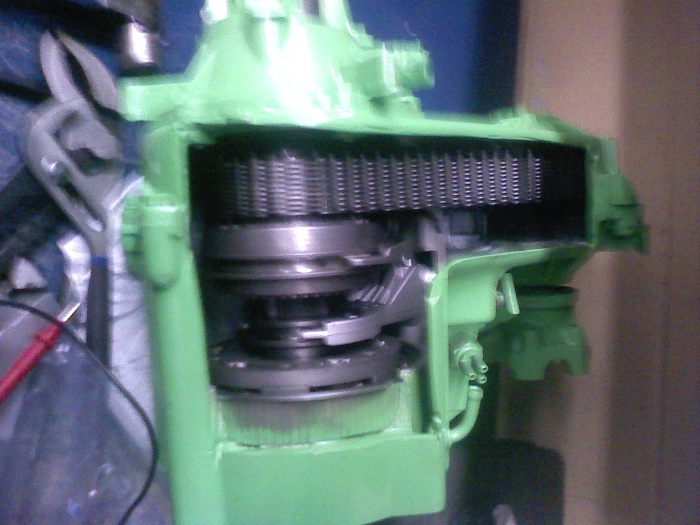

Disassembly

1. Remove front companion yoke. Discard washer and nut. Shift transfer case to 4L and remove extension housing. Remove rear bearing snap ring. Using 2 screwdrivers under each tab, remove retainer housing. Remove rear case and oil pump as an assembly.

2. Remove oil pump pick-up screen and tube from rear case. Remove oil pump. Remove "O" ring from oil pump and discard. Do not separate oil pump halves. Pump must be replaced as an assembly if necessary.

3. Remove mode spring. Using a soft hammer, tap front output shaft upward and remove with drive chain as an assembly. Remove mainshaft, mode fork and shift rail as an assembly. Remove mode fork and shift rail from synchronizer sleeve.

4. Mark synchronizer sleeve position for reassembly reference. Remove synchronizer sleeve from mainshaft. Remove synchronizer hub snap ring. Remove synchronizer hub, stop ring and drive sprocket. Slide range fork pin out of sector.

5. Remove range fork and shift hub as an assembly. Remove range lever from sector shaft. Remove shift sector, bushing and "O" ring. Remove shift detent pin, spring and plug. Remove front bearing retainer. Remove input gear snap ring.

6. Press input and low range gear assembly from input gear bearing. Remove low range gear snap ring. Remove input gear retainer, thrust washers and input gear from low range gear.

7. Remove all oil seals. Remove magnet from front case. Remove front bearing snap ring. Using a plastic hammer, remove front bearing. Press input gear bearing from front case.

8. Using slide hammer and internal puller, remove input gear pilot bearing. Press bearings from drive sprocket. Using internal puller and slide hammer, remove output shaft rear bearing

Cleaning And Inspection

Reassembly

1. Lubricate all parts with Dexron III before installing. Install output shaft front bearing with NEW snap ring. Install output shaft oil seal in front case. Install snap ring on NEW input gear bearing.

2. Press input gear bearing so snap ring is seated against case. Using press, install NEW input gear pilot bearing. Assemble low range gear, input gear, thrust washers and retainer.

3. Install snap ring. Ensure snap ring is seated in low range gear groove. Start input gear shaft into bearing in front case. Press input shaft gear into bearing.

4. Install input gear snap ring. Install oil seal in front bearing retainer. Apply a 1/8" bead of silicone sealant to retainer mating surface. Align oil channel in retainer with oil feed hole in case. Install retainer on case. Tighten bolts to specification.

5. Install sector shaft "O" ring and bushing. Install range sector in case. Install range lever and nut. Install detent, detent spring and plug. Tighten to specification. . Install NEW pads and fork rail bushings on range fork. Install range fork and shift hub.

6. Ensure range fork pin is engaged with range sector slot. Press front bearing in drive sprocket until bearing is flush with bore edge. Install rear bearing until bearing is flush with lower edge of chamfer in bearing bore.

7. Install inserts and spring in synchronizer hub. Install sprocket on mainshaft. Install synchronizer stop ring on mainshaft. Ensure stop ring is seated. Install synchronizer hub on mainshaft. Align and seat hub inserts on stop ring lugs. Install synchronizer hub snap ring.

8. Install synchronizer sleeve on hub. Ensure sleeve is positioned so beveled spline ends are facing stop ring. Ensure sleeve tooth is aligned (centered) over each synchronizer strut. Gear clash will occur if strut and sleeve teeth are misaligned. Install NEW pads on mode fork. Engage mode fork in synchronizer sleeve. Install mainshaft and fork assembly in case. Ensure mode fork shift rail is seated in both range fork bushings.

9. Install output shaft and drive chain assembly. Install mode spring on shift rail. Using bearing driver, install output shaft rear bearing. Lubricate bearing after installation. Install seal in oil pump feed housing. Install oil pump in housing. Tighten to specification.

10.Install oil pick-up tube "O" ring in oil pump. Prime oil pump by pouring ATF into pump through pick-up tube opening. Install oil pump and pick-up tube in case. Ensure oil screen is properly positioned. Install magnet in front case. Apply 1/8" bead of silicone sealer to front case. Install rear case. Tighten to specification. . Ensure mainshaft splines are engaged with oil pump inner gear and a washer is used on bolts at dowel locations.

11.install rear bearings in retainer. Apply 1/8" bead of silicone sealer and install retainer to case. Install rear retainer snap ring. Install extension housing. Install front companion yoke. Install NEW gasket on vacuum switch. Install vacuum switch in case. Fill transfer case with Dexron III.

.

Last edited by jeff2285; 12-13-2010 at 08:05 PM.

#6

Newbie

Thread Starter

Join Date: Dec 2010

Posts: 24

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

You guys are awesome. Thank you so much. I changed my Tcase fluid, draining was easy bcuz the fluid was very low. I filled it back up to the fill hole, drove it 3 miles, and when I got back the underside of my Jeep around the Tcase was wet with ATF. I searched for the highest point of origin for the leak and it seems to be coming from the seal for the main driveshaft to the rear diff. Probably why it was low. The rubber boot that clamps over the driveshaft and the seal cover had slipped off the seal cover. The seal cover had also slipped rearward and didn't notice it until I started messing with the boot and it slipped back into place. Should I plan on replacing that rear seal when I do my chain inspection?

Trending Topics

#8

Senior Member

Join Date: Apr 2010

Location: Bonney Lake, WA

Posts: 615

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1989

Model: Cherokee

Engine: 4.0 IL6

My Tcase recently went out and I found it much easier and cheaper to just throw another one in. I found a used one out of a non-modified cherokee with relatively low miles for $75 and put it in. There are plenty of Cherokees in junkyards out there with working tranfer cases that you can pick up for much less than a new one, or even for less than the cost of a new chain.

#9

Member

Join Date: Nov 2010

Posts: 194

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1994

Model: Cherokee

Engine: 4.0

Wow $75 for a used xfercase, not here.

The only thing that really wears out is the chain, if you keep your fluid topped off, your xfercase will last you a lifetime

Used xfer case= used stretched chain

Replace the chain and seal and you'll have a "new" xfercase

The only thing that really wears out is the chain, if you keep your fluid topped off, your xfercase will last you a lifetime

Used xfer case= used stretched chain

Replace the chain and seal and you'll have a "new" xfercase

Thread

Thread Starter

Forum

Replies

Last Post

eepjeep

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

1

04-06-2020 03:19 PM

Vegas101

Stock Grand Cherokee Tech. All ZJ/WJ/WK Non-modified/stock questions go here!

0

09-04-2015 11:52 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)