Electrical help needed

#1

Junior Member

Thread Starter

98XJ 4.0 AT. When I step on the brake pedal my rear washer and wiper starts running. Foot off the break brake, washer stops and the wiper continues for a few more passes then stops. Dash switch seem to operate normal. Where do I start looking for this gremlin?

Last edited by Superslow; 07-16-2016 at 11:59 AM. Reason: correct

#2

CF Veteran

Join Date: May 2012

Location: Lost in the wilds of Virginia

Posts: 7,964

Received 952 Likes

on

767 Posts

Year: 1998 Classic (I'll get it running soon....) and 02 Grand

Model: Cherokee (XJ)

Engine: 4.0

Are you saying your washer is broken?

Are you saying your washer is broken?And what's that got to do with the brake pedal????

I suggest starting with the grounds at the back. When things get weird, grounds are the first suspect.

CCKen just posted a pic of the ground locations a couple of days ago, here.

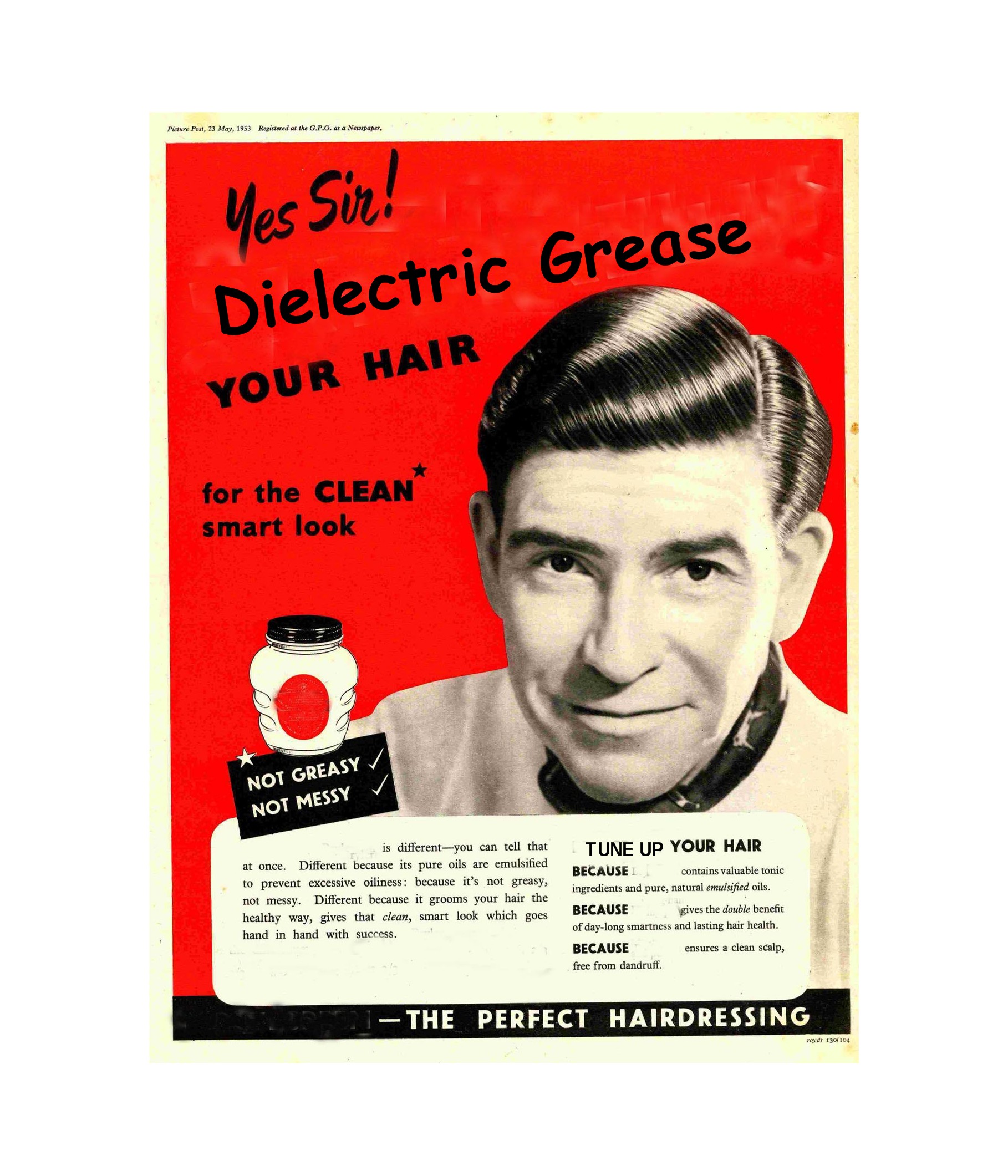

Make sure the metal is shiny clean, both the connector and the sheet metal. Use dielectric grease on both before you reassemble them.

If that isn't it, check the wiring to your hatch.

#4

CF Veteran

Join Date: May 2012

Location: Lost in the wilds of Virginia

Posts: 7,964

Received 952 Likes

on

767 Posts

Year: 1998 Classic (I'll get it running soon....) and 02 Grand

Model: Cherokee (XJ)

Engine: 4.0

Yes, dielectric grease, the correct product for this application, rather than a product which is basically the same thing but with the addition of various chemicals to ensure there is NO ALuminum OXidation when aluminum conductors are used with copper or steel connectors.

#5

Junior Member

Thread Starter

Are you saying your washer is broken?

Are you saying your washer is broken?And what's that got to do with the brake pedal????

I suggest starting with the grounds at the back. When things get weird, grounds are the first suspect.

CCKen just posted a pic of the ground locations a couple of days ago, here.

Make sure the metal is shiny clean, both the connector and the sheet metal. Use dielectric grease on both before you reassemble them.

If that isn't it, check the wiring to your hatch.

Thanks for the link to the rear grounds. I didn't know they existed. Sounds like a reasonable source of the problem. I think I will stay away from dielectric grease as it is an insulator and don't see how that would have a positive effect on a ground connection.

#6

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Edited OP to fix typo. Hopefully that clarifies things a bit. The problem has now become intermittent which of course is very frustrating.

Thanks for the link to the rear grounds. I didn't know they existed. Sounds like a reasonable source of the problem. I think I will stay away from dielectric grease as it is an insulator and don't see how that would have a positive effect on a ground connection.

Thanks for the link to the rear grounds. I didn't know they existed. Sounds like a reasonable source of the problem. I think I will stay away from dielectric grease as it is an insulator and don't see how that would have a positive effect on a ground connection.

#7

CF Veteran

Join Date: May 2012

Location: Lost in the wilds of Virginia

Posts: 7,964

Received 952 Likes

on

767 Posts

Year: 1998 Classic (I'll get it running soon....) and 02 Grand

Model: Cherokee (XJ)

Engine: 4.0

No problem, that's a common misunderstanding (shared by our friend Ken, here).

It's all about contact pressure. When you make a proper connection, the pressure at the actual contact points is high enough that the dielectric grease is reduced to a film of just a few microns, and at that thickness, it does not inhibit the flow of electrons (electricity). That's what it's designed to do.

However, it DOES prevent oxygen from reaching the metal, thus preventing corrosion, which WILL interfere with your connection.

That's why dielectric grease for electrical connections is required or recommended in many military, aerospace, and marine applications where reliability is literally a matter of life and death.

Corrosion is your enemy. Dielectric grease prevents corrosion. It's what it was developed to do. It is your friend.

Instead of dielectric grease, Ken recommends NOALOX, which is basically a plastic base, with zinc powder and silicon dioxide (silica). You can see these ingredients in the MSDS here.

(Or just do a search on "MSDS NOALOX".) Here's what you'll find:

Polybutene <80

Zinc Dust 20

Silicon Dioxide <5

Hmm. Looks like there's some variability in the ratio of polybutene to silica (silicon dioxide). Silica is an abrasive, by the way. Great for electrical contacts!

I also note that the MSDS says its water solubility is "moderate". Oh. That's really good for ground connections that might be exposed to water.

Oh, by the way, if you look up the electrical characteristics of polybutene you'll find it's very similar to silicone dielectric grease. I see the that the volume resistivity of polybutene is 10^15, and the volume resistivity of dielectric grease is.... uh.... 10^15.

Hmmm. 10^15 vs. 10^15. Yeah, that's pretty similar, I'd say. It's close, anyway....

In both products, the base material is an insulator which is there to prevent oxygen from reaching the contact surface. With the NOALOX, the zinc is added, not to improve conductivity, but to act as a sacrificial element which will corrode before the aluminum conductors or connectors that it is protecting. It eventually gets used up, but very slowly.

In fact, here's what one competitor has to say:

Many contact greases have copper, zinc or other metals blended into a grease to increase conductivity. In a study for an aerospace company in 1985 it was concluded that putting metal into grease does not help conductivity. In many cases it reduces conductivity. The United States Department of the Interior Bureau of Reclamation states in their Facilities instruction Journal Volume 3-3 Electrical Connections for Power Circuits in section 6.3.2that, "Use of grease with embedded zinc particles will cause a poorer connection due to the lower conductivity of zinc".

You can find an excellent write-up on the whole topic here. He includes some interesting tests to prove his points, and concludes (as do all knowlegeable engineers):

In regular low voltage multiple-pin circuit connectors, such as automotive applications, flooding with a proper insulating grease of low-viscosity dielectric grease is perfectly acceptable unless a manufacturer recommends against it. The grease should have good stability and not contain metals in any form, and be specifically designed for use as a dielectric grease. This generally is a silicone dielectric grease, although some Teflon based greases are acceptable.

In single low-voltage terminals or connections, such as metal-to-metal joints, grounds, or battery posts, almost any pure grease of light viscosity will be acceptable. Caution should be used with greases containing metallic powders to be sure any metal is compatible with the embedded grease metal. Connection enhancement from embedded metal powder is very minor, if it exists at all, and there is increased risk of bad connections if the metal powder has any interaction with the base metals.

In single low-voltage terminals or connections, such as metal-to-metal joints, grounds, or battery posts, almost any pure grease of light viscosity will be acceptable. Caution should be used with greases containing metallic powders to be sure any metal is compatible with the embedded grease metal. Connection enhancement from embedded metal powder is very minor, if it exists at all, and there is increased risk of bad connections if the metal powder has any interaction with the base metals.

So, you can take the word of Internet experts who can't get past the "Run, Marybelle! It's wun o' them thar INSULATORS!!!" (so they go around recommending a product that is an insulator) or you can do some reading on your own....

OR, you could take the recommendations of several generations of engineers in the marine, aerospace, automotive, communications, and military, who have studied the matter intensively for decades and have concluded the dielectric grease is the correct product to use for most electrical connections that would benefit from a paste or grease type product, and that NOALOX (and its knockoffs) is suited to AC power connections where aluminum connectors or conductors are used (which is what it was designed for in the first place).

Your choice, of course.

Trending Topics

#8

Junior Member

Thread Starter

Hold on! This is the internet! Where is the straw man and red herring in your argument? You even provide sources without me asking for them 10 times…what are you thinking!??! I just might have to rethink what my boss told me 35 years ago when I worked at a gas station "don't get the silicone grease on the contacts, it's an insulator."

#9

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Well Dr. BlueRidge, I see you've done your research, albeit a waste of time.

Do your listening audience a favor and remove all ground connections in your engine bay and apply dielectric grease to the connections then get back with how it worked out for you.

Here's the only thing I can see what dielectric grease could be used for.

Do your listening audience a favor and remove all ground connections in your engine bay and apply dielectric grease to the connections then get back with how it worked out for you.

Here's the only thing I can see what dielectric grease could be used for.

#10

Member

My rear wiper would randomly turn on as well (among other anomalies); harness was cracked and frayed between gate and roof.

Grabbed a good one from another XJ with excess.

Been good for 6 months or so. GL

Grabbed a good one from another XJ with excess.

Been good for 6 months or so. GL

#11

CF Veteran

Join Date: May 2012

Location: Lost in the wilds of Virginia

Posts: 7,964

Received 952 Likes

on

767 Posts

Year: 1998 Classic (I'll get it running soon....) and 02 Grand

Model: Cherokee (XJ)

Engine: 4.0

It's rather like trying to explain that the moon landing was real.

#12

CF Veteran

Join Date: May 2012

Location: Lost in the wilds of Virginia

Posts: 7,964

Received 952 Likes

on

767 Posts

Year: 1998 Classic (I'll get it running soon....) and 02 Grand

Model: Cherokee (XJ)

Engine: 4.0

Hold on! This is the internet! Where is the straw man and red herring in your argument? You even provide sources without me asking for them 10 times…what are you thinking!??! I just might have to rethink what my boss told me 35 years ago when I worked at a gas station "don't get the silicone grease on the contacts, it's an insulator."

Was his name Ken?

Let us know what you find with your grounds. I'd say the odds are about 9 in 10 it's going to either be your grounds or the harness, like SouthSeaPirate mentioned.

#14

Newbie

Join Date: Mar 2015

Location: Bend, Oregon

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

I have a theory. Check the wire harness inside the boot where it enters the rear hatch. the wires inside the boot are flexed every time the hatch opens. Over the years the wire gets brittle, cracks and breaks. I think that when you apply the brake the wire is shorting on the washer/wiper wire ect. My bet is you'll find a whole bunch of crusty broken wires to fix.

Thread

Thread Starter

Forum

Replies

Last Post

aa7kn

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

15

06-18-2016 12:50 AM

Joe W

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

5

04-30-2016 04:54 PM

GaiaXJ

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

5

04-27-2016 11:15 AM

HockeyFan56

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

15

04-19-2016 05:50 AM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)