frozen leaf spring hardware

#1

Junior Member

Thread Starter

Join Date: Jul 2009

Posts: 74

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2001

Model: Cherokee

Engine: inline 6

i have a new set of heavy load leaf springs that i want to put on my 2001 but all the bolts are frozen. i sprayed them once a day for a week with pb blaster and they still won't budge.

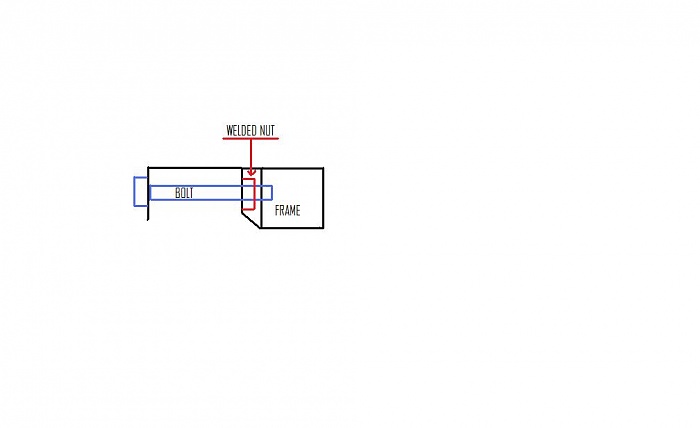

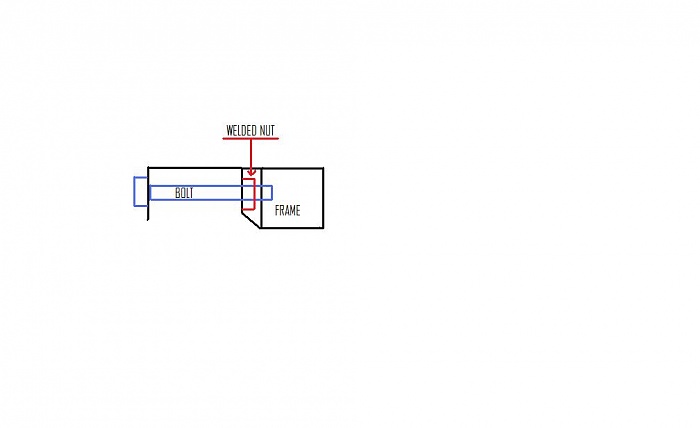

my idea now is to cut everything off and get new hardware. cutting the ubolts and the bolt that goes through the shackle will be no problem, it's the bolt on the front of the leaf that goes into the unibody that is making me a little nervous. i'm figuring that there is a welded nut inside the uni body and after i cut the bolt i can drill it out and put a helicoil in there.

i know a lot of you have had this same problem, so my question is have any of you done it this way or a different way?

my idea now is to cut everything off and get new hardware. cutting the ubolts and the bolt that goes through the shackle will be no problem, it's the bolt on the front of the leaf that goes into the unibody that is making me a little nervous. i'm figuring that there is a welded nut inside the uni body and after i cut the bolt i can drill it out and put a helicoil in there.

i know a lot of you have had this same problem, so my question is have any of you done it this way or a different way?

#2

CF Veteran

Join Date: Jun 2009

Location: Michigan

Posts: 2,132

Received 290 Likes

on

239 Posts

Year: 1987 MJ, 1998 XJ, 1973 J2000, 89 waggy

Model: Comanche (MJ)

Engine: 4.0L H.O

just a little help for ya when it comes to the front leaf spring mount...

There is actually a nut thats welded to a small pocket.. the bolt just passes through the frame... so a heli-coil is not possible because as soon as you start to drill it out the nut will simply break free from the pocket its welded to.. (if it doesn't already)

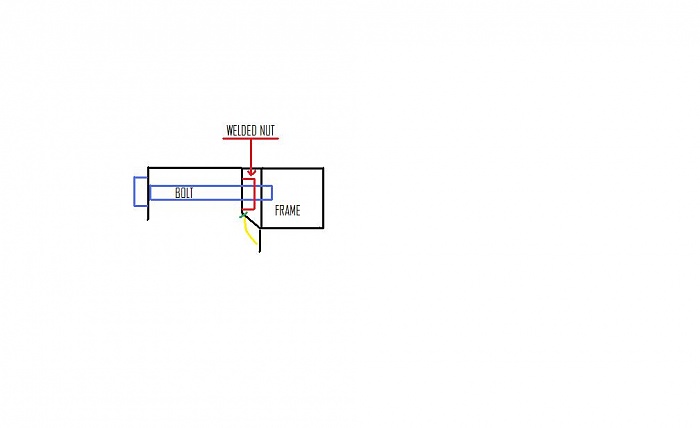

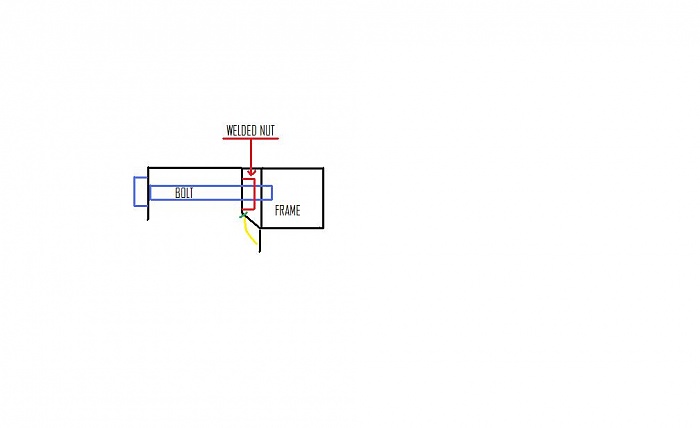

easy way to get at it is to cut a small window toward the very bottom of the mount and fold it open.. then you can get at it to do as you please...

be for warned though that when dealing with this pesky nut in any plan of attack. Many Many swear words will come pouring out like a dam overflowing from rain water.... i'll snap some pics of my XJ here in a few minutes for ya so you can see

There is actually a nut thats welded to a small pocket.. the bolt just passes through the frame... so a heli-coil is not possible because as soon as you start to drill it out the nut will simply break free from the pocket its welded to.. (if it doesn't already)

easy way to get at it is to cut a small window toward the very bottom of the mount and fold it open.. then you can get at it to do as you please...

be for warned though that when dealing with this pesky nut in any plan of attack. Many Many swear words will come pouring out like a dam overflowing from rain water.... i'll snap some pics of my XJ here in a few minutes for ya so you can see

#3

Seasoned Member

Join Date: Apr 2011

Location: Westminster,CO

Posts: 441

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2001

Model: Cherokee

Engine: 4.0L

What I did on the front bolt is, I cut the leaf off then there is a sleeve around the rubber bushing I cut that off then I cut the rubber bushing off with a box cutter .. now you should just have the bolt and the sleeve that was in the bushing ... the sleeve gets rusted to the bolt keeping it from coming out but there is a seem on the sleeve ... leave the bolt in the unibody a little bit and hit the seem with a air hammer the sleeve will open up and you will be able to remove the bolt without out cutting it

#4

Junior Member

Thread Starter

Join Date: Jul 2009

Posts: 74

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2001

Model: Cherokee

Engine: inline 6

i have put helicoils in welded nuts before, but i think i will try cutting everything off like un150 did. i dont want to cut a hole unless its the last resort. i live in new england and i know if i cut that hole it will start rusting away immediately even if i paint it.

#5

what are you using to on the bolts?

I always use an 18" breaker bar and that always gets it done

I always use an 18" breaker bar and that always gets it done

#6

CF Veteran

Join Date: Jun 2009

Location: Michigan

Posts: 2,132

Received 290 Likes

on

239 Posts

Year: 1987 MJ, 1998 XJ, 1973 J2000, 89 waggy

Model: Comanche (MJ)

Engine: 4.0L H.O

well after you slip the sleeve off as UN150 stated and you find out that the nut that was welded on may have broken lose..... as they do fairly often. its one of the easiest ways to remedy the problem. plus some quick mig welding after you set it up to your choosing and some either paint or can bedliner spray will solve the rust issue

#7

Junior Member

Thread Starter

Join Date: Jul 2009

Posts: 74

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2001

Model: Cherokee

Engine: inline 6

well after you slip the sleeve off as UN150 stated and you find out that the nut that was welded on may have broken lose..... as they do fairly often. its one of the easiest ways to remedy the problem. plus some quick mig welding after you set it up to your choosing and some either paint or can bedliner spray will solve the rust issue

Trending Topics

#8

Senior Member

Join Date: Nov 2010

Location: Cloquet, MN

Posts: 976

Likes: 0

Received 5 Likes

on

5 Posts

Year: 2000 Ltd.

Model: Cherokee

Engine: 4.0L I6

I just changed my rear springs. The key is an air impact wrench and a breaker bar. You don't want to just reaf on the breaker bar though because you risk breaking the weld nut loose.

What I did was just hammer on it with the impact for quite a while, trying to loosen it, then tightening it, then loosening it etc. Keep going with that process and it will break the thing loose. Once in a while I would put the breaker bar on and move it back and forth as much as I could to help loosen things up for the impact. It may take a while (probably took 15-30 minutes each side for me with my compressor recharging every few minutes) but the bolts will break loose. Once they break loose, don't just run them all the way out. Back them out a little, then run them all the way back in, then back them out a little more, and repeat. This helps clean the rust off the threads and keeps from ruining the weld nut.

What I did was just hammer on it with the impact for quite a while, trying to loosen it, then tightening it, then loosening it etc. Keep going with that process and it will break the thing loose. Once in a while I would put the breaker bar on and move it back and forth as much as I could to help loosen things up for the impact. It may take a while (probably took 15-30 minutes each side for me with my compressor recharging every few minutes) but the bolts will break loose. Once they break loose, don't just run them all the way out. Back them out a little, then run them all the way back in, then back them out a little more, and repeat. This helps clean the rust off the threads and keeps from ruining the weld nut.

#9

try getting the pb in between the bushing and the

"frame" side that stuff will find its way to the threads

"frame" side that stuff will find its way to the threads

#10

Member

Join Date: Dec 2010

Location: belvidere, il

Posts: 133

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

the best way is to cut the opening like the pic and heat the nut with a small torch, and if it is frozen to the leaf eye i just torch the crap out of the bushing until it comes.

Thread

Thread Starter

Forum

Replies

Last Post

her89

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

9

09-26-2015 12:06 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)