Cowl Intake Effectiveness

#1

Junior Member

Thread Starter

Join Date: Apr 2011

Location: Reno, NV

Posts: 47

Likes: 0

Received 5 Likes

on

4 Posts

Year: 1996

Model: Cherokee

Engine: 4.0 L

For some time I have been studying Cold Air Intakes in general and Cowl Intakes/Snorkels. The previous owner of my '96 Cherokee had added a large K&N filter and metal intake tube that drew air from a region on the other side of the engine from the throttle body and near the firewall (about 6 inches away). I have used extensively my Ultragauge connected to the OBD II port to monitor key parameters including instant and average mpg, manifold vacuum, coolant temperature and intake air temperature.

Today, I installed my version of the cowl intake. I cleaned and sealed the stock airbox, opened a 3" diameter hole in the side facing the firewall, and inserted and bonded a Spectre 3" adapter. I then cut a 3" diameter hole in the driver's side cowl and sealed another Spectre adapter to the cowl. I then connected the modified airbox to the cowl with Spectre 3" flexible intake hose.

The point of this post is that I carefully measured the intake air temperature before and after the modification. Before the modification, driving up to Lake Tahoe from Reno with outside temperature of 65 F, the intake temp ranged from 177 F to 192 F. After the cowl intake addition (same day, same course, several hours later) with an outside air temperature of 58 F, the intake air temperature ranged from 78 to 103 F. Idling for about 10 minutes (no movement) brought the intake air temp up to 138F. Engine off (shopping in Auto Parts store) with about a 10 minute heat soak brought the Intake air temp up to 146 F. In both of these latter instances, upon driving away, the intake temp quickly dropped to 78 F (about 5 minutes). Turning to the freeway at 65 mph, the intake air temp dropped to 65 F. The temperature drop was a function of vehicle speed consistent with a significant pressure build-up at the base of the windshield/cowl area.

As yet, I have made no additional mpg or power measurements, however, it is clear that this approach clearly generates a very effective cold air intake. I will replace the stock air filter with a Rugged Ridge dry filter shortly. My effort to get away from the K&N oiled filter approach has succeeded.

YMMV

Today, I installed my version of the cowl intake. I cleaned and sealed the stock airbox, opened a 3" diameter hole in the side facing the firewall, and inserted and bonded a Spectre 3" adapter. I then cut a 3" diameter hole in the driver's side cowl and sealed another Spectre adapter to the cowl. I then connected the modified airbox to the cowl with Spectre 3" flexible intake hose.

The point of this post is that I carefully measured the intake air temperature before and after the modification. Before the modification, driving up to Lake Tahoe from Reno with outside temperature of 65 F, the intake temp ranged from 177 F to 192 F. After the cowl intake addition (same day, same course, several hours later) with an outside air temperature of 58 F, the intake air temperature ranged from 78 to 103 F. Idling for about 10 minutes (no movement) brought the intake air temp up to 138F. Engine off (shopping in Auto Parts store) with about a 10 minute heat soak brought the Intake air temp up to 146 F. In both of these latter instances, upon driving away, the intake temp quickly dropped to 78 F (about 5 minutes). Turning to the freeway at 65 mph, the intake air temp dropped to 65 F. The temperature drop was a function of vehicle speed consistent with a significant pressure build-up at the base of the windshield/cowl area.

As yet, I have made no additional mpg or power measurements, however, it is clear that this approach clearly generates a very effective cold air intake. I will replace the stock air filter with a Rugged Ridge dry filter shortly. My effort to get away from the K&N oiled filter approach has succeeded.

YMMV

#3

CF Veteran

Join Date: Nov 2011

Location: Las Vegas, NV - St. George, UT

Posts: 1,314

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1996

Model: Cherokee

Engine: 4.0

In for pics. I looked up the pricing for these parts too. Way less than the actual Spectre cowl intake. If you have part numbers can you post those too?

#4

CF Veteran

Join Date: Oct 2011

Location: South Mills, NC

Posts: 1,812

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: Rebuilt 4.0L I6

I have the same problem you had. I was getting 18 mpg now I'm getting 12. I used the same flex as you did and my intake temperatures are really high. I don't understand how you fixed it. I would greatly appreciate your help.

#5

Senior Member

Join Date: Mar 2012

Location: Bellevue, WA

Posts: 512

Likes: 0

Received 1 Like

on

1 Post

Year: 1998

Model: Cherokee

Engine: 4.0L

How do you deal with rain coming into your intake?

The full Spectre intake takes air from the passenger side, which is the dry side.

The air actually comes from the driver side, where the grill is open and can get moisture in..

The full Spectre intake takes air from the passenger side, which is the dry side.

The air actually comes from the driver side, where the grill is open and can get moisture in..

#7

Junior Member

Thread Starter

Join Date: Apr 2011

Location: Reno, NV

Posts: 47

Likes: 0

Received 5 Likes

on

4 Posts

Year: 1996

Model: Cherokee

Engine: 4.0 L

In my original post, I didn't include photos because there are so many excellent descriptions of this approach here on the forum. But some more detail is appropriate. I used 2 Spectre 8146 Intake Duct Mounting Plates, 1 Spectre 8741 3" Air Duct Hose and 2 Spectre 8703 T-bolt Clamps for a total of $50.12 including tax. To bond the mounting plate to the stock airbox, I used VersaChem 5 Minute Epoxy Part Number 46509, specifically because it is formulated to remain flexible and bond to both plastic and rubber. To seal the mounting plate to the cowl, I used VersaChem Mega Black High Temperature Silicone Gasket Maker. Before applying sealants and the epoxy, all surfaces were cleaned with hot water and Simple Green Cleaner, then rinsed with isopropyl alcohol and air dried.

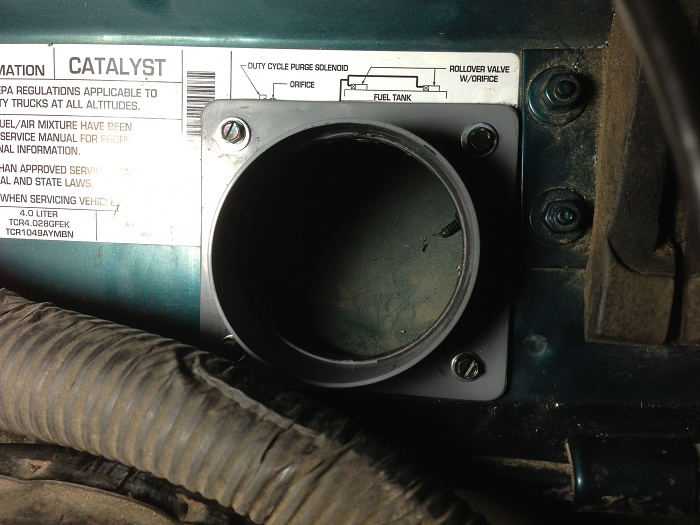

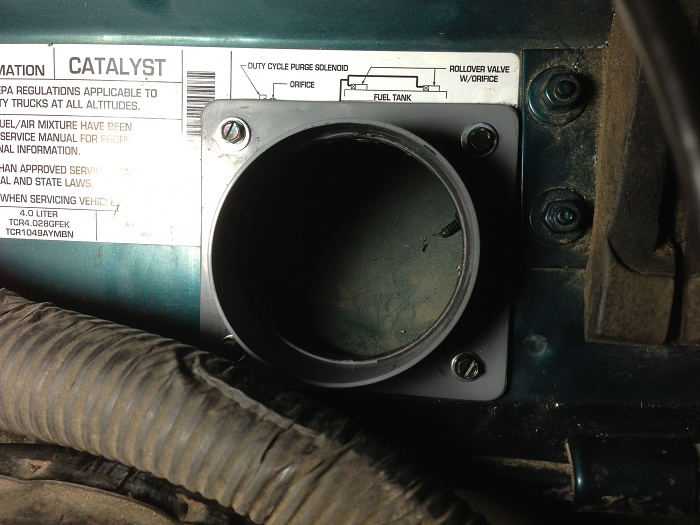

In the following are pictures of the install including an overview of the system, a view of the hose coupling to the airbox, a view of the hose coupling to the cowl, a picture of the adapter mounted to the cowl and one of the adapter mounted to the airbox. A few other detailed comments could prove helpful. As one can see, the adapter to the cowl is mechanically reinforced with 4 sheet metal screws. The seal is established with the silicone seal under the surface of the adapter. I used the Spectre adapters because they only required 3" diameter holes to be cut as opposed to the 3.5" diameter that would be required by ABS drain pipe used by others.

The placement of the adapter in the airbox was really facilitated by the Spectre mounting plate. As one can see from the accompanying image, I cut a 3" diameter hole through the airbox located to clear the air cleaner insert and only penetrate the flat surface of the airbox face. Using a Dremel tool, I shaped the flat surface of the mounting plate to clear the internal shape of the airbox. When finished, I could inset the modified mounting plate through the hole from the inside and press it flush to the airbox interior surface. After cleaning, I liberally applied the epoxy to the surface of the mounting plate, wiped away the excess polymer and clamped it in place for a 30 minute cure. After it had set, I drilled three holes and added the three sheet metal screws to add mechanical strength. I then used the Dremel tool to cut off the threads projecting into the airbox and added a thin layer of the epoxy as a sealant. I also closed off the drain holes in the otherwise stock airbox using the epoxy and Painter's Tape to provide a closed-off mold. When bolting the stock box in place, the fasteners were sealed with the silicone gasket material. The original air inlet to the airboc was sealed with a piece of flexible plastic cut from a splash guard and bonded with the epoxy. When finished the fill area of the airbox used by the stock air filter was clear of any obstruction.

In using the Spectre air duct hose, I was concerned about the internal surface of the hose impeding airflow. However after studying the number of 90 degree bends in the route from cowl to airbox, I concluded that the resulting airflow impedance would be dominated by those bends. The air duct hose material is well designed for the underhood temperatures that will be encountered. I had considered reflective insulation wrap but the anticipated airflow rates of 50 to 400 cfm suggested that there was little time in the induction tract for thermal equilibration, so this was rejected for the sake of simplicity.

I had considered the full Spectre cowl intake, but rejected this on the basis of the small oil-wetted filter. From similar considerations, I have never been impressed with the K&N filter approach. At best, they provide short term (until clogged) high air flow capacity (irrelevant to the operational utility of the Jeep 4.0L) with troubling filtration capability. My requirements were threefold: Reliability, fuel economy and engine longevity. Lowering intake air temperature arguably impacts all three considerations. The high surface area stock air filter approach provides the best particulate protection with no impact on required air flow.

I really appreciate the insight of those Forum members who came up with this cowl approach. And for the snorkel perspective, I plan to keep all immersions at or below the middle of my headlights!

Hope this helps someone.

In the following are pictures of the install including an overview of the system, a view of the hose coupling to the airbox, a view of the hose coupling to the cowl, a picture of the adapter mounted to the cowl and one of the adapter mounted to the airbox. A few other detailed comments could prove helpful. As one can see, the adapter to the cowl is mechanically reinforced with 4 sheet metal screws. The seal is established with the silicone seal under the surface of the adapter. I used the Spectre adapters because they only required 3" diameter holes to be cut as opposed to the 3.5" diameter that would be required by ABS drain pipe used by others.

The placement of the adapter in the airbox was really facilitated by the Spectre mounting plate. As one can see from the accompanying image, I cut a 3" diameter hole through the airbox located to clear the air cleaner insert and only penetrate the flat surface of the airbox face. Using a Dremel tool, I shaped the flat surface of the mounting plate to clear the internal shape of the airbox. When finished, I could inset the modified mounting plate through the hole from the inside and press it flush to the airbox interior surface. After cleaning, I liberally applied the epoxy to the surface of the mounting plate, wiped away the excess polymer and clamped it in place for a 30 minute cure. After it had set, I drilled three holes and added the three sheet metal screws to add mechanical strength. I then used the Dremel tool to cut off the threads projecting into the airbox and added a thin layer of the epoxy as a sealant. I also closed off the drain holes in the otherwise stock airbox using the epoxy and Painter's Tape to provide a closed-off mold. When bolting the stock box in place, the fasteners were sealed with the silicone gasket material. The original air inlet to the airboc was sealed with a piece of flexible plastic cut from a splash guard and bonded with the epoxy. When finished the fill area of the airbox used by the stock air filter was clear of any obstruction.

In using the Spectre air duct hose, I was concerned about the internal surface of the hose impeding airflow. However after studying the number of 90 degree bends in the route from cowl to airbox, I concluded that the resulting airflow impedance would be dominated by those bends. The air duct hose material is well designed for the underhood temperatures that will be encountered. I had considered reflective insulation wrap but the anticipated airflow rates of 50 to 400 cfm suggested that there was little time in the induction tract for thermal equilibration, so this was rejected for the sake of simplicity.

I had considered the full Spectre cowl intake, but rejected this on the basis of the small oil-wetted filter. From similar considerations, I have never been impressed with the K&N filter approach. At best, they provide short term (until clogged) high air flow capacity (irrelevant to the operational utility of the Jeep 4.0L) with troubling filtration capability. My requirements were threefold: Reliability, fuel economy and engine longevity. Lowering intake air temperature arguably impacts all three considerations. The high surface area stock air filter approach provides the best particulate protection with no impact on required air flow.

I really appreciate the insight of those Forum members who came up with this cowl approach. And for the snorkel perspective, I plan to keep all immersions at or below the middle of my headlights!

Hope this helps someone.

Trending Topics

#8

Junior Member

Thread Starter

Join Date: Apr 2011

Location: Reno, NV

Posts: 47

Likes: 0

Received 5 Likes

on

4 Posts

Year: 1996

Model: Cherokee

Engine: 4.0 L

This question has asked and well treated in virtually all discussions of the cowl intake approach. Its an important question to consider, but it has been thoroughly addressed. To recount, there are major drainage paths on either side of the cowl (driver's and passenger's); the area accessed by my approach on the drivers side is also fully shielded from direct access by rain; crossing to the passenger side from the stock airbox port would significantly increase the duct length causing unnecessary flow reduction; eliminating the stock airbox to shorten the access length would be an unacceptable system compromise. I say unacceptable because it would add the cost of a sealed filtration system at best, and at worst would require an oil based K&N technology filter approach.

Finally, for water to flow from the cowl to the duct to the airbox, it would have to be at a level more than 2 inches above the bottom surface of the cowl. Many individuals on this Forum have reported experiments ranging from flooding the cowl with a garden hose to driving through a monsoon with no water found in the bottom of the airbox.

Finally, for water to flow from the cowl to the duct to the airbox, it would have to be at a level more than 2 inches above the bottom surface of the cowl. Many individuals on this Forum have reported experiments ranging from flooding the cowl with a garden hose to driving through a monsoon with no water found in the bottom of the airbox.

The following users liked this post:

downs (06-16-2020)

#10

Junior Member

Thread Starter

Join Date: Apr 2011

Location: Reno, NV

Posts: 47

Likes: 0

Received 5 Likes

on

4 Posts

Year: 1996

Model: Cherokee

Engine: 4.0 L

I haven't analyzed mpg yet but I'll record some instantaneous readings today. So far, I only meant to say that the cold air intake aspect of the modification was clearly very effective.

#14

Junior Member

Thread Starter

Join Date: Apr 2011

Location: Reno, NV

Posts: 47

Likes: 0

Received 5 Likes

on

4 Posts

Year: 1996

Model: Cherokee

Engine: 4.0 L

Yes, as I tried to indicate in the detail post, I sealed off the original air entry to the stock airbox by cutting a piece of flexible plastic from a cheap splash guard (mudflap). I cut and trimmed it to a size that fit between the edge of the airbox and the molded rib near the original inlet. Still made sure the added material came below the ridge for the air filter. Then I lathered the inside surface of the airbox with the epoxy and clamped the new material to the airbox. After the epoxy had set, I drilled holes for two retaining sheet metal screws to reinforce the patch mechanically. As with the other sheet metal screws, I cut off the excess threads with the Dremel tool. After bolting the airbox in place, I tested the water tightness by filling it to the air filter line (using a 3" rubber cap seal on the new inlet) and let it sit overnight. Still full in the morning and no sign of wetness around the box. I'm certain the system is sealed at least to water at atmospheric pressure all the way to the cowl. Although my original intention was to fabricate a real cold air intake, I saw no reason not to treat it as a pseudo snorkel!

#15

Junior Member

Thread Starter

Join Date: Apr 2011

Location: Reno, NV

Posts: 47

Likes: 0

Received 5 Likes

on

4 Posts

Year: 1996

Model: Cherokee

Engine: 4.0 L

Today, I monitored the Instantaneous mpg numbers returned by the Ultra-Gauge monitor. But first I should say that when I purchased this Cherokee about 1 year ago, I replaced the speedometer gear to correct the speedo/odometer for the 33" tires I am running. I checked and calibrated the speedometer with a GPS system and found an error of less than 0.1%. I also calibrated the odometer using a tracking program locked to the GPS signal (iPhone extravagance). The odometer error was more like 0.3%.

Anyway, I did several runs on flat stretches of the freeway, averaged two directions. The results: 23.9 mpg @ 55 mph; 22.7 mpg @ 60 mph and 20.8 mpg @ 65 mph. This represents about 2 mpg better than my numbers before the install. I then did my standard run up through the mountains to home. This is a 1,200 foot elevation change over about 2.8 miles. I run this at 45 mph as the Jeep can stay in the same gear over this run and I'm looking for systematic changes in coolant temperature. Here I recorded 10.9 mpg vs. my typical value of 9.3 mpg before the install. From these results, I conclude that there is no mpg reduction, and quite possibly a 6 to 10% gain in fuel economy.

Of course, the picture is a little more complicated. The day I did the install, I did it just after changing the oil to 5W-30 Full Synthetic (Castrol Edge) and flushing and re-lubricating the rear differential. The differential fluid before the change had an disturbingly gritty feel! Also the previous hill climb numbers were with a quarter tank of fuel and this latter run was done with a full 20 gallons. Also, today it was about 4 degrees cooler than yesterday.

My 45 mph testing gave a coolant temperature at the turnoff of 221 F. The run today after the install and oil service gave a peak temperature of 203.

As a result of all of this, your mpg and temperature problem can't be related to the cowl intake install unless there is a major air leak or the installation inadvertently triggered an electrical control system problem. To the best I can tell from here, you should have the same results I have.

Nothing is ever as simple as it seems!

Anyway, I did several runs on flat stretches of the freeway, averaged two directions. The results: 23.9 mpg @ 55 mph; 22.7 mpg @ 60 mph and 20.8 mpg @ 65 mph. This represents about 2 mpg better than my numbers before the install. I then did my standard run up through the mountains to home. This is a 1,200 foot elevation change over about 2.8 miles. I run this at 45 mph as the Jeep can stay in the same gear over this run and I'm looking for systematic changes in coolant temperature. Here I recorded 10.9 mpg vs. my typical value of 9.3 mpg before the install. From these results, I conclude that there is no mpg reduction, and quite possibly a 6 to 10% gain in fuel economy.

Of course, the picture is a little more complicated. The day I did the install, I did it just after changing the oil to 5W-30 Full Synthetic (Castrol Edge) and flushing and re-lubricating the rear differential. The differential fluid before the change had an disturbingly gritty feel! Also the previous hill climb numbers were with a quarter tank of fuel and this latter run was done with a full 20 gallons. Also, today it was about 4 degrees cooler than yesterday.

My 45 mph testing gave a coolant temperature at the turnoff of 221 F. The run today after the install and oil service gave a peak temperature of 203.

As a result of all of this, your mpg and temperature problem can't be related to the cowl intake install unless there is a major air leak or the installation inadvertently triggered an electrical control system problem. To the best I can tell from here, you should have the same results I have.

Nothing is ever as simple as it seems!