Machinists Corner

#106

CF Veteran

Join Date: Sep 2010

Location: Warsaw, IN

Posts: 2,844

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2000,1990,1999

Model: Cherokee

Engine: 4.0

WOW! I just was doing some exploring and found this thread. I'm a retired toolmaker with about 50 years of experience building plastic injection molds. Most of our cavities were manually machined and/or ram EDM burned. The shop I retired from had just gotten a Haas CNC vertical mill, but the boss decided I was too old to bother teaching me. I'm basically an old Bridgeport guy with a lot of Cincinnati vertical mill time. I've made or modified lots of speed parts in my day, especially manifold adapters for carburetors.

I'd love to teach basic metalworking, but nobody cares anymore. I'd be perfect for the high school shop classes. I don't have any machines of my own and I get very frustrated using a hand drill and sawzall to do what would take me 10 minutes on a Bridgeport! The most sophisticated equipment I ever used was a DRO! OH...wait! Ram EDM, small 40 watt table-top machine.

There is one thing I'd like to make. That's a fixture for a floor jack to lift the front of a jeep by the D30 so it's balanced. If I ever get the time, I'll post a drawing.

I'd love to teach basic metalworking, but nobody cares anymore. I'd be perfect for the high school shop classes. I don't have any machines of my own and I get very frustrated using a hand drill and sawzall to do what would take me 10 minutes on a Bridgeport! The most sophisticated equipment I ever used was a DRO! OH...wait! Ram EDM, small 40 watt table-top machine.

There is one thing I'd like to make. That's a fixture for a floor jack to lift the front of a jeep by the D30 so it's balanced. If I ever get the time, I'll post a drawing.

#107

Old fart with a wrench

Yeah, I have another of those lost arts. Lacing and truing spoked motorcycle wheels. Everything is mags now. I did enduros, motocross and flat track bikes.

#108

CF Veteran

Join Date: Feb 2013

Location: Belton S.C.

Posts: 1,286

Likes: 0

Received 1 Like

on

1 Post

Year: 1998

Model: Cherokee

Engine: 4.0

Exactly. It is near impossible for us to hire an experienced manual machinist. Everyone is CNC, I don't understand why the tech schools put such an emphasis on CNC. So you can run production machinery, what happens when you need a one off custom part or the CNC breaks how ya gonna fix it? No one has the ability to figure out how to make things using only a mill and lathe. CNC has it's uses but too many people call themselves machinist when actually they are button pushers. Personally I love the days when I get an oddball part and have to figure it out. I don'ts need no stinkin CNC haha.

#109

Senior Member

Join Date: Nov 2013

Location: Vernon NJ

Posts: 616

Likes: 0

Received 3 Likes

on

3 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

Exactly. It is near impossible for us to hire an experienced manual machinist. Everyone is CNC, I don't understand why the tech schools put such an emphasis on CNC. So you can run production machinery, what happens when you need a one off custom part or the CNC breaks how ya gonna fix it? No one has the ability to figure out how to make things using only a mill and lathe. CNC has it's uses but too many people call themselves machinist when actually they are button pushers. Personally I love the days when I get an oddball part and have to figure it out. I don'ts need no stinkin CNC haha.

#110

CF Veteran

Join Date: Jul 2012

Location: Andover, VT

Posts: 2,982

Received 236 Likes

on

183 Posts

Year: 1999

Model: Cherokee (XJ)

Engine: 4.0 L

I happen to be one of those young people with manual experience. I took machine shop class 6 times in high school, as well as welding a couple times.

I traveled from NH to Missouri with my hop teacher to compete in SkillsUSA which is a national competition. I placed 24th out of 48. Guess which two categories I got last in; g-code for a milled part and a turned part. I easily would've been top 10 had I known g-code better.

Went on to do some more manual work at community college but focused more on the design side. Now I'm a teacher's assistant at the university teaching students to run old bridgeports.

Unfortunately manual machining is quickly becoming much more of a hobby than an industry. It's just so easy to draw a part in cad, set up a machine, and hit go.

I miss running that old Bridgeport with no DRO. Standing on a stool to tighten the drawbar with a wrench. Moving the belt to change speeds..

I traveled from NH to Missouri with my hop teacher to compete in SkillsUSA which is a national competition. I placed 24th out of 48. Guess which two categories I got last in; g-code for a milled part and a turned part. I easily would've been top 10 had I known g-code better.

Went on to do some more manual work at community college but focused more on the design side. Now I'm a teacher's assistant at the university teaching students to run old bridgeports.

Unfortunately manual machining is quickly becoming much more of a hobby than an industry. It's just so easy to draw a part in cad, set up a machine, and hit go.

I miss running that old Bridgeport with no DRO. Standing on a stool to tighten the drawbar with a wrench. Moving the belt to change speeds..

#115

Old fart with a wrench

Right there with you guys. I would rather chuck some thing in the manual engine lathe and set up some thing on the bridge port. It is more fun that way. I bored out my throttle body on the engine lathe here at work. I remember running a 31" diameter disk on an engine lathe at one shop I worked at. That was awesome.

Last edited by dave1123; 06-14-2016 at 01:18 PM.

#116

Senior Member

Join Date: Nov 2013

Location: Vernon NJ

Posts: 616

Likes: 0

Received 3 Likes

on

3 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

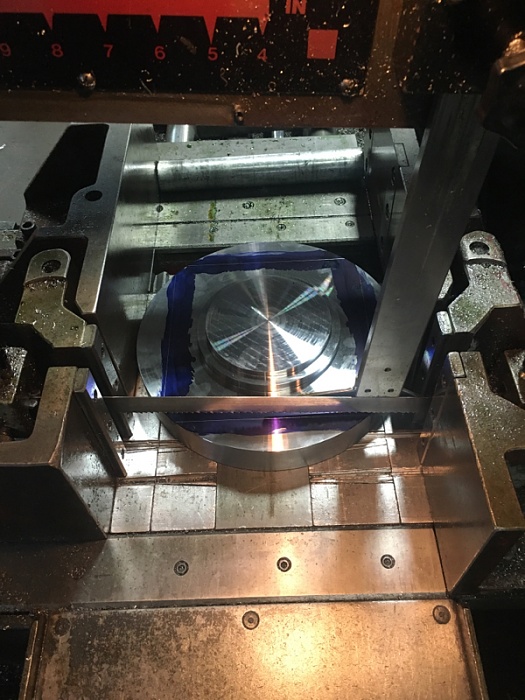

The disks I was machining were for a radar tower. I had to mount them with a crane to a custom made fixture on the lathe. Getting both sides flat and parallel with in .001 was fun, then putting grooves on both sides that were concentric to the center and to each other within .005 was interesting. Each one weighed about 60 pounds and were made from 11/16" think steel that I had to cut down to about 5/8". If that company had night time hours I would go back just to make those.

#117

Old fart with a wrench

The disks I was machining were for a radar tower. I had to mount them with a crane to a custom made fixture on the lathe. Getting both sides flat and parallel with in .001 was fun, then putting grooves on both sides that were concentric to the center and to each other within .005 was interesting. Each one weighed about 60 pounds and were made from 11/16" think steel that I had to cut down to about 5/8". If that company had night time hours I would go back just to make those.

Last edited by dave1123; 06-14-2016 at 06:22 PM.

#119

Senior Member

Join Date: Nov 2013

Location: Vernon NJ

Posts: 616

Likes: 0

Received 3 Likes

on

3 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

That is exactly what I was cutting. With the big whole and everything. There was a fixed ring and the rotating ring. Both had grooves that had to be concentric with each other once assembled. The grooves were for an electronics pack. These were for air traffic control radar systems. Once all of the turning and mill work was done they got copper plated and a black oxide coating.

#120

Old fart with a wrench

Yeah, I live here in Syracuse where GE built a lot of radar stuff. They had large bedspring mobile antennas for the Army rotating constantly to see how long they lasted without problems. I think they were for anti-aircraft rocket launchers. They used a lot of local job shops for some of their parts. Unfortunately GE, Carrier, Chrysler, Bristol Mayers, Syracuse China, and GM's Fisher Guide Div. have all left this place and the economy sucks. No manufacturing jobs and fewer job shops. It makes me think about Detroit. About the only thing left here is plastic molding and Anaren Microwave. Even the Phillips broadband plant moved out.

OH....wait! The New Process/New Venture plant has folded. I wonder how many transfer cases are still in stock?

OH....wait! The New Process/New Venture plant has folded. I wonder how many transfer cases are still in stock?

Last edited by dave1123; 06-16-2016 at 05:27 AM.