Dee Dee

#31

Member

Thread Starter

Join Date: Apr 2012

Location: ri

Posts: 212

Likes: 0

Received 1 Like

on

1 Post

Year: 1996

Model: Cherokee

Engine: 4.0 HO

I was searching for cheap stuff do do with my time off so I replaced the rear brake lines all the way to the master cylinder with epoxy coated lines. (But can't figure out what happened to the pictures.)

Then I started picking away at the cargo area project again.

I had some industrial carpet and some pllywood hanging around and some spare cargo netting from a project on the boat.

A little sawing and gluing and some trimming with the disk grinder on the sheet metal and I had 3 boxes in place.

On the passenger side I laced some bungee cord into the netting and tacked it right to the boxes, then carpeted it, which was a pain in the butt. It looked okay, but not great.

On the drivers side pocket I just tacked the carpet onto to the box and cut a hole for the pocket. It was much quicker and will look a lot better if I take it to the upholstery guy and have the hole for the pocked edged, I'll probably have the edge that goes over the wheel well done at the same time.

I like that you can see the stuff in the bottom of the pocket thru the net but it really doesn't look that great so I may cut a new passenger side and dump the net idea.

So this whole project, pulling the back seat and replacing it with a flip-up extension for the rear deck, making the wooden pockets and doing a lot of fussy cuts to the sheet metal and some really heavy carpet was a pain, and took maybe 30 hours.

The pockets are nice, I've got someplace to stash the trailer hitch ball, a rain coat, the ratchet straps, stuff like that, but I only picked up about 3" in width and 6" in length in the cargo area. The couple of inches I picked up under the back seat really aren't good for much.

Over all I've got to say the project really wasn't worth the trouble and I still need to fabricate some sort of a window sill.

Then I started picking away at the cargo area project again.

I had some industrial carpet and some pllywood hanging around and some spare cargo netting from a project on the boat.

A little sawing and gluing and some trimming with the disk grinder on the sheet metal and I had 3 boxes in place.

On the passenger side I laced some bungee cord into the netting and tacked it right to the boxes, then carpeted it, which was a pain in the butt. It looked okay, but not great.

On the drivers side pocket I just tacked the carpet onto to the box and cut a hole for the pocket. It was much quicker and will look a lot better if I take it to the upholstery guy and have the hole for the pocked edged, I'll probably have the edge that goes over the wheel well done at the same time.

I like that you can see the stuff in the bottom of the pocket thru the net but it really doesn't look that great so I may cut a new passenger side and dump the net idea.

So this whole project, pulling the back seat and replacing it with a flip-up extension for the rear deck, making the wooden pockets and doing a lot of fussy cuts to the sheet metal and some really heavy carpet was a pain, and took maybe 30 hours.

The pockets are nice, I've got someplace to stash the trailer hitch ball, a rain coat, the ratchet straps, stuff like that, but I only picked up about 3" in width and 6" in length in the cargo area. The couple of inches I picked up under the back seat really aren't good for much.

Over all I've got to say the project really wasn't worth the trouble and I still need to fabricate some sort of a window sill.

#32

Member

Thread Starter

Join Date: Apr 2012

Location: ri

Posts: 212

Likes: 0

Received 1 Like

on

1 Post

Year: 1996

Model: Cherokee

Engine: 4.0 HO

I tow a boat with my Cherokee and the 9" brakes have always been an issue.

A couple of years ago a friend of mine had a set of 10" xj "Police" drums hanging around

and I bought them for $40. I figured there had to be a way to upgrade the "Chubby Girl on High Heels"

but I blew it off and the drums ended up in the shed.

A coupe of months ago I started on a brake job and found way too much play in the drivers side rear axle,

...and a mess of gear oil in the passenger side drum.

So it was time (220k mi) for bearings and seals and a little experimenting.

There's a nice write-up on pulling the half-shafts here by a member named 99slcherokee.

The only thing I have to add to his write-up is:

Definately don't try to change the bearings without a slide hammer type puller.

Don't bother with a seal puller, yank the seal and bearing at the same time with the slide hammer.

I did some searching and it turns out the 97-99 Dakota used the same 29 spline 'Corporate'

rear end as the '96 SE, but I couldn't find a decent Dakota donor.

Between the road salt and the sea air up here in New England, you may as well be cruising around

in an acid bath.

I ended springing for a mess of new parts. But it was worth it, I'm really happy with the way it turned out.

Everything but the arms for the emergency brakes is still available in factory parts or after-market kits.

I found an '88 Dakota with 10" brakes with what I believe was an 8.25 and I was able to use parts from

that as well, but I can't swear all the parts from an '88 will be interchangeable.

It should work but all I know for sure is the parts listed in this post will fit the 'corporate' 8.25 that came in the '96.

I bought the factory backer plates from a local dealership for under $90, they're seriously heavy duty

and bolt right up to the '96 29 spline 8.25 with no modification.

There's a 5 th hole at the bottom of the backer plate, but no 5th stud on my flange .

I was tempted to drill out the flange and add the 5 th stud, but I wasn't sure this project was going

to fly at the time I mounted the backing plate.

If you're going to go for the mod, definitely add the extra stud. Mount the plate and use it as a guide

to drill the flange on the differential.

I used the '97-'99 shoes and everything went right together without a hitch.

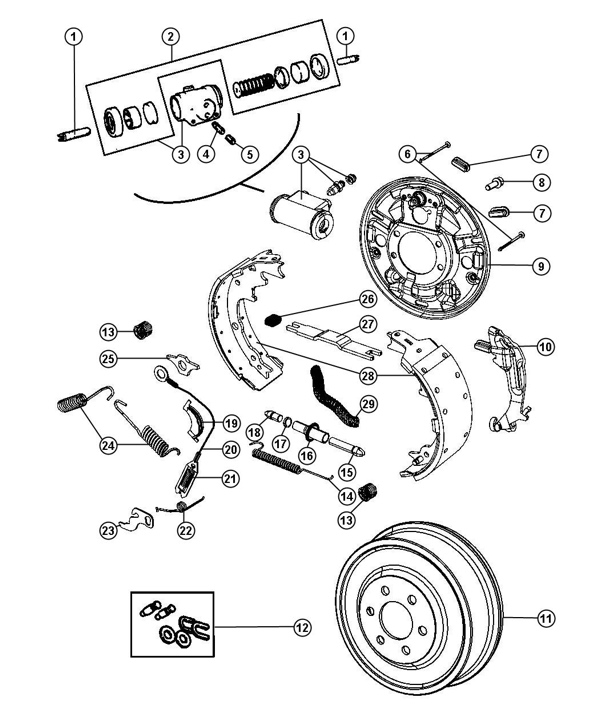

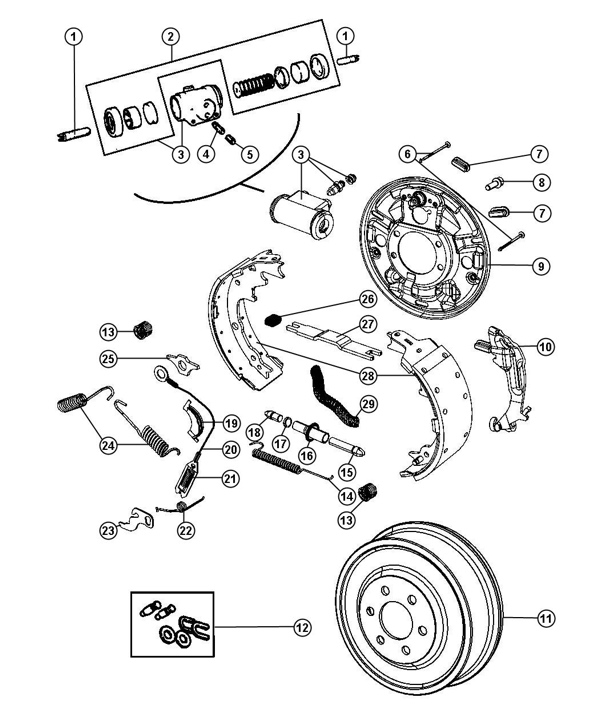

Parts:

Nearly everything is stock parts for a 1998 Dakota 5.2L w/ a 5 speed, but you need top specify

10" brakes when your ordering.

The backerplate (#9) is available from the dealer.

The springs, cables, adjusters etc come in 2 master kits.

The wheel cylinder (#3) is available, as is a re-build kit (#2) if you find a used cylinder.

I hit a couple of minor snags.

The brake cylinder piston rods (#1) are seriously over-priced, but all the used ones I found were rusted

to spit so I threw the extra $ and bought the OEM new.

The arms for the parking brake (#10) are no longer available.

I found a 1988 Dakota with a 6 cyl and 10" drums in the junk yard and grabbed the arms from that.

The gold colored strut (#27) in the picture below is supposed to be what goes on the '98, but they won't

work with the parking brake arms from the '88.

I'm not sure if the '98 arms are radically different from the '88s or the parts catalog was messed up,

but when you find the donor parking brake arms, grab the struts too.

I never actually saw a '97-'99 strut or parking brake lever, so I can't say for sure if they will work or not,

But everything else worked so I can't see why they wouldn't.

I couldn't find a wheel cylinder worth rebuilding so I bought one new.

It's only slightly larger then the one from the 9" and will work just fine with the existing master cylinder.

There's also no problem getting the factory rims over the 10" drums.

So I get this all assembeled...

...slap on my "Police" drums and go for a test drive.

and I'm getting this scraping noise.

Long story short, The Cherokee Police drum set up is 10 x 2" and the Dakota is 10 x 2 1/2.

So it's back to the parts place for another set of drums.

(Note that the '98 drums are 6 lug, you'll need to order drums for an '88)

If you don't count the $40 I spent on the police drums, the whole project only cost me $150 more

then the major brake overhaul I was going to do anyway.

and I picked up almost 16 extra square inches of braking surface on the drums and 17.5 square inches

of brake pad. Plus a lot more surface area to dissipate heat.

I'll post a shorter version of this in the tech section later today.

A couple of years ago a friend of mine had a set of 10" xj "Police" drums hanging around

and I bought them for $40. I figured there had to be a way to upgrade the "Chubby Girl on High Heels"

but I blew it off and the drums ended up in the shed.

A coupe of months ago I started on a brake job and found way too much play in the drivers side rear axle,

...and a mess of gear oil in the passenger side drum.

So it was time (220k mi) for bearings and seals and a little experimenting.

There's a nice write-up on pulling the half-shafts here by a member named 99slcherokee.

The only thing I have to add to his write-up is:

Definately don't try to change the bearings without a slide hammer type puller.

Don't bother with a seal puller, yank the seal and bearing at the same time with the slide hammer.

I did some searching and it turns out the 97-99 Dakota used the same 29 spline 'Corporate'

rear end as the '96 SE, but I couldn't find a decent Dakota donor.

Between the road salt and the sea air up here in New England, you may as well be cruising around

in an acid bath.

I ended springing for a mess of new parts. But it was worth it, I'm really happy with the way it turned out.

Everything but the arms for the emergency brakes is still available in factory parts or after-market kits.

I found an '88 Dakota with 10" brakes with what I believe was an 8.25 and I was able to use parts from

that as well, but I can't swear all the parts from an '88 will be interchangeable.

It should work but all I know for sure is the parts listed in this post will fit the 'corporate' 8.25 that came in the '96.

I bought the factory backer plates from a local dealership for under $90, they're seriously heavy duty

and bolt right up to the '96 29 spline 8.25 with no modification.

There's a 5 th hole at the bottom of the backer plate, but no 5th stud on my flange .

I was tempted to drill out the flange and add the 5 th stud, but I wasn't sure this project was going

to fly at the time I mounted the backing plate.

If you're going to go for the mod, definitely add the extra stud. Mount the plate and use it as a guide

to drill the flange on the differential.

I used the '97-'99 shoes and everything went right together without a hitch.

Parts:

Nearly everything is stock parts for a 1998 Dakota 5.2L w/ a 5 speed, but you need top specify

10" brakes when your ordering.

The backerplate (#9) is available from the dealer.

The springs, cables, adjusters etc come in 2 master kits.

The wheel cylinder (#3) is available, as is a re-build kit (#2) if you find a used cylinder.

I hit a couple of minor snags.

The brake cylinder piston rods (#1) are seriously over-priced, but all the used ones I found were rusted

to spit so I threw the extra $ and bought the OEM new.

The arms for the parking brake (#10) are no longer available.

I found a 1988 Dakota with a 6 cyl and 10" drums in the junk yard and grabbed the arms from that.

The gold colored strut (#27) in the picture below is supposed to be what goes on the '98, but they won't

work with the parking brake arms from the '88.

I'm not sure if the '98 arms are radically different from the '88s or the parts catalog was messed up,

but when you find the donor parking brake arms, grab the struts too.

I never actually saw a '97-'99 strut or parking brake lever, so I can't say for sure if they will work or not,

But everything else worked so I can't see why they wouldn't.

I couldn't find a wheel cylinder worth rebuilding so I bought one new.

It's only slightly larger then the one from the 9" and will work just fine with the existing master cylinder.

There's also no problem getting the factory rims over the 10" drums.

So I get this all assembeled...

...slap on my "Police" drums and go for a test drive.

and I'm getting this scraping noise.

Long story short, The Cherokee Police drum set up is 10 x 2" and the Dakota is 10 x 2 1/2.

So it's back to the parts place for another set of drums.

(Note that the '98 drums are 6 lug, you'll need to order drums for an '88)

If you don't count the $40 I spent on the police drums, the whole project only cost me $150 more

then the major brake overhaul I was going to do anyway.

and I picked up almost 16 extra square inches of braking surface on the drums and 17.5 square inches

of brake pad. Plus a lot more surface area to dissipate heat.

I'll post a shorter version of this in the tech section later today.

Last edited by Marcucco; 10-20-2013 at 10:26 AM. Reason: typo

#33

Member

So I started on the "Up Country" leaf spring package this afternoon......

Even after spraying the leaf spring bolts twice a week for a month, everything's still frozen solid, so Im not going to waste a lot of time.

The grinder and sawzall are going to earn their keep tomorrow, then were gong to introduce DeeDee to the "blue wrench".

Got my fingers crossed.....

Even after spraying the leaf spring bolts twice a week for a month, everything's still frozen solid, so Im not going to waste a lot of time.

The grinder and sawzall are going to earn their keep tomorrow, then were gong to introduce DeeDee to the "blue wrench".

Got my fingers crossed.....

Just so I'm clear... you used a grinder to cut away the springs and the bushings around those front bilts so that you could apply heat directly to the bolt/nut/frame area?

Last edited by Bucko; 10-21-2017 at 05:16 PM.