Question on possible overtorque on head bolt

#1

Junior Member

Thread Starter

Join Date: Nov 2014

Posts: 53

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

Just a quick question on a clearwater head install that I did on my 2001 XJ last night. Went through the proper torque procedure, 22, 45 (x2), then 110 on all bolts except 11 (drivers side front), which was 100 with thread sealant.

I went through and checked them all again at 110, but on the front passengers side (#12 I guess it would be) the wrench didn't click. I think it got hung up internally, and then popped free. The bolt turned probably another 10-15 degrees or so before this happened.

So I guess my worry is overtorque now. Should I pull that bolt and install a new one? Or leave it? Will that likely cause any issues down the line?

If it needs to be replaced, can I purchase just one bolt? Or will I need the set?

**Also, on the rear drivers side bolt (the one that needs to be installed when the head goes in), I could not fit the deep well socket, and the torque wrench in there. It was too tall to clear, so I used a 3/8 ratchet wrench and 1/2 socket and just did it "by feel" using how tight the torqued bolts "felt" as my gauge. I think it is pretty close. How did you guys do this?**

Thanks

I went through and checked them all again at 110, but on the front passengers side (#12 I guess it would be) the wrench didn't click. I think it got hung up internally, and then popped free. The bolt turned probably another 10-15 degrees or so before this happened.

So I guess my worry is overtorque now. Should I pull that bolt and install a new one? Or leave it? Will that likely cause any issues down the line?

If it needs to be replaced, can I purchase just one bolt? Or will I need the set?

**Also, on the rear drivers side bolt (the one that needs to be installed when the head goes in), I could not fit the deep well socket, and the torque wrench in there. It was too tall to clear, so I used a 3/8 ratchet wrench and 1/2 socket and just did it "by feel" using how tight the torqued bolts "felt" as my gauge. I think it is pretty close. How did you guys do this?**

Thanks

#2

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Just a quick question on a clearwater head install that I did on my 2001 XJ last night. Went through the proper torque procedure, 22, 45 (x2), then 110 on all bolts except 11 (drivers side front), which was 100 with thread sealant.

I went through and checked them all again at 110, but on the front passengers side (#12 I guess it would be) the wrench didn't click. I think it got hung up internally, and then popped free. The bolt turned probably another 10-15 degrees or so before this happened.

So I guess my worry is overtorque now. Should I pull that bolt and install a new one? Or leave it? Will that likely cause any issues down the line?

If it needs to be replaced, can I purchase just one bolt? Or will I need the set?

**Also, on the rear drivers side bolt (the one that needs to be installed when the head goes in), I could not fit the deep well socket, and the torque wrench in there. It was too tall to clear, so I used a 3/8 ratchet wrench and 1/2 socket and just did it "by feel" using how tight the torqued bolts "felt" as my gauge. I think it is pretty close. How did you guys do this?**

Thanks

I went through and checked them all again at 110, but on the front passengers side (#12 I guess it would be) the wrench didn't click. I think it got hung up internally, and then popped free. The bolt turned probably another 10-15 degrees or so before this happened.

So I guess my worry is overtorque now. Should I pull that bolt and install a new one? Or leave it? Will that likely cause any issues down the line?

If it needs to be replaced, can I purchase just one bolt? Or will I need the set?

**Also, on the rear drivers side bolt (the one that needs to be installed when the head goes in), I could not fit the deep well socket, and the torque wrench in there. It was too tall to clear, so I used a 3/8 ratchet wrench and 1/2 socket and just did it "by feel" using how tight the torqued bolts "felt" as my gauge. I think it is pretty close. How did you guys do this?**

Thanks

I would replace that bolt. But you'll have to buy a new set in order to get another bolt.

As far as torqueing #14, use a double box end wrench, one end fitting the head bolt and the other end (?). Use a hex bit socket to fit the (?) box end attached to the torque wrench. Use the torque correction in the following link.

http://www.freeinfostuff.com/TorqueE...eExtension.htm

Edit: If the link won't open, copy and paste it to your browser window. Go to Brian's info page.

Last edited by CCKen; 12-13-2015 at 12:14 PM.

#3

Bolt 11-

If you snapped the bolt or ripped the threads on the block.....you are screwed anyway.

But I doubt that happened at 100lbs.

My guess is the sealant had begun to set up and what you heard/felt was the sealant letting loose.

As for 14-

By the time you torqued all the other bolts you should know the amount of muscle is took, using a breaker bar of the same length or a box end with cheater of the same length you would have gotten near dead on without the torque wrench.

You could have cut the stud off the bolt and used short socket.....moving your ground cable elsewhere.

If you snapped the bolt or ripped the threads on the block.....you are screwed anyway.

But I doubt that happened at 100lbs.

My guess is the sealant had begun to set up and what you heard/felt was the sealant letting loose.

As for 14-

By the time you torqued all the other bolts you should know the amount of muscle is took, using a breaker bar of the same length or a box end with cheater of the same length you would have gotten near dead on without the torque wrench.

You could have cut the stud off the bolt and used short socket.....moving your ground cable elsewhere.

#4

BTW,

Using a jack......you could have removed the bolt at the passenger side motor mount and lowered the engine an inch or so, this may have changed the angle of the bolt enough to get the socket and torque wrench on.

More than one was to solve a problem.

Using a jack......you could have removed the bolt at the passenger side motor mount and lowered the engine an inch or so, this may have changed the angle of the bolt enough to get the socket and torque wrench on.

More than one was to solve a problem.

#5

CF Veteran

Join Date: Jul 2013

Location: Monett, MO.

Posts: 7,554

Likes: 0

Received 14 Likes

on

14 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

I would replace that bolt. But you'll have to buy a new set in order to get another bolt.

As far as torqueing #14, use a double box end wrench, one end fitting the head bolt and the other end (?). Use a hex bit socket to fit the (?) box end attached to the torque wrench. Use the torque correction in the following link.

http://www.freeinfostuff.com/TorqueE...eExtension.htm

Edit: If the link won't open, copy and paste it to your browser window. Go to Brian's info page.

As far as torqueing #14, use a double box end wrench, one end fitting the head bolt and the other end (?). Use a hex bit socket to fit the (?) box end attached to the torque wrench. Use the torque correction in the following link.

http://www.freeinfostuff.com/TorqueE...eExtension.htm

Edit: If the link won't open, copy and paste it to your browser window. Go to Brian's info page.

Yes this is the correct way to do this I have had to do this exact thing over the last 40-50 yrs a lot of times. Things don't always fit like they should and this is either learned from doing it wrong more than once like me or in a lot of cases from schooling.

With the investment you have a complete set of head bolts are cheap for the amount of time they could last if done properly. Ken has given you information that you will use all your life priceless!

#6

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

This is the way I did #14 (after removing and reinstalling my head the second time).

Cut off the threaded portion of the #14 bolt before installation. You can get a shallow socket on it for proper torqueing. The threaded portion of the left hand bolts were used at the factory for lifting the engine, using a special lifting device. The treaded portion of these bolts are not needed in the #14 position. See pic.

This is the way I addressed the bonding strap from #14 to the firewall. With the threaded portion of #14 removed I had to find another firewall to engine bonding strap place to secure it.

Old spot:

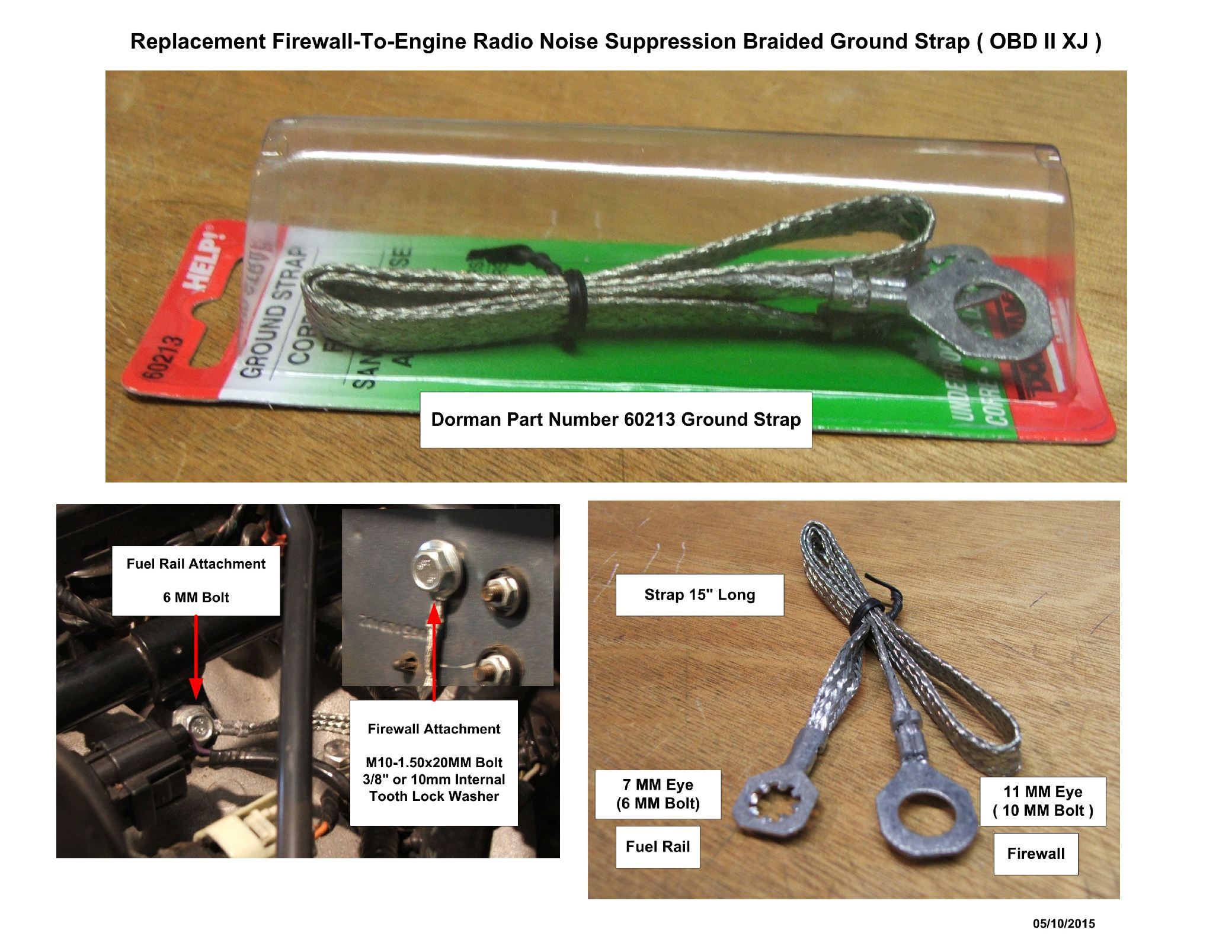

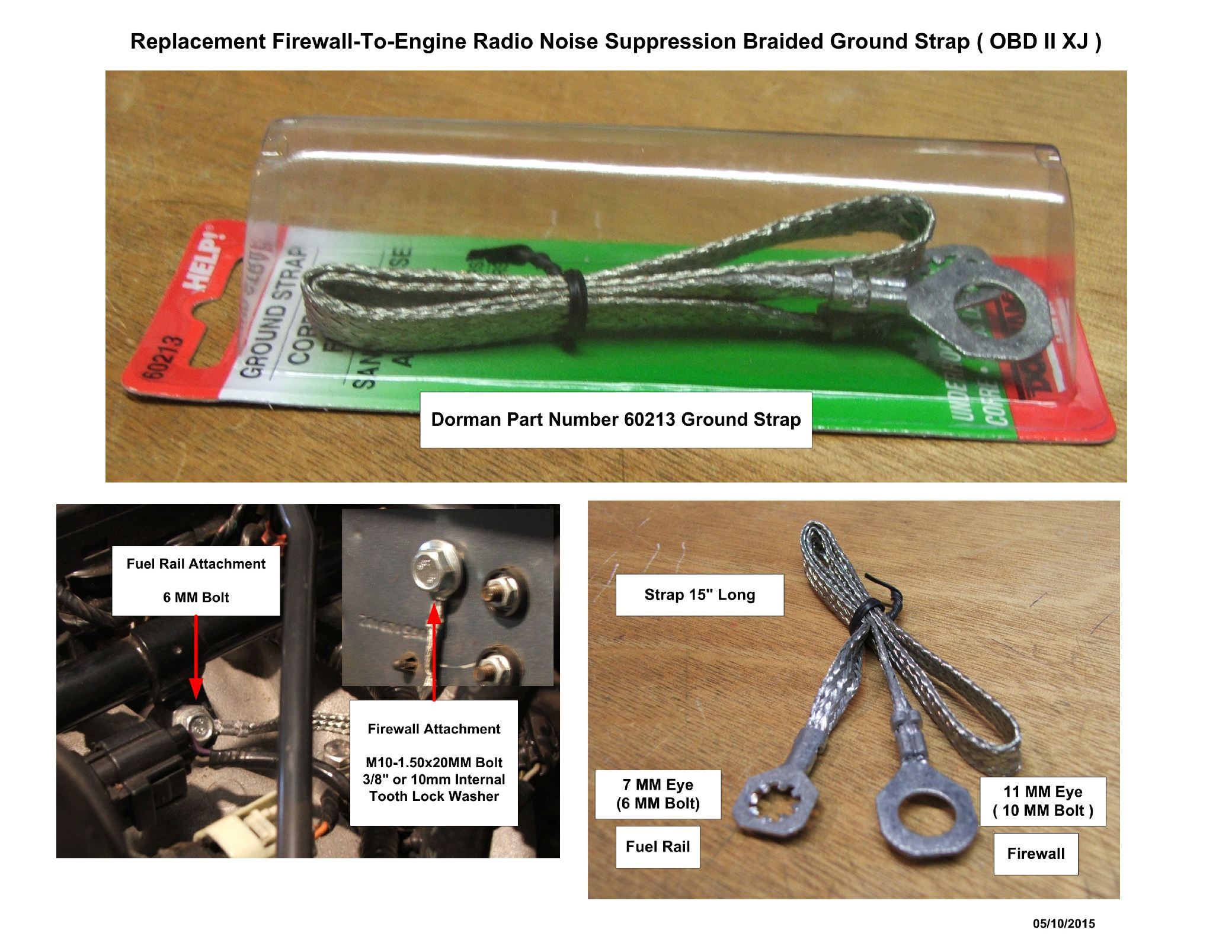

Revised spot with new bonding strap:

Cut off the threaded portion of the #14 bolt before installation. You can get a shallow socket on it for proper torqueing. The threaded portion of the left hand bolts were used at the factory for lifting the engine, using a special lifting device. The treaded portion of these bolts are not needed in the #14 position. See pic.

This is the way I addressed the bonding strap from #14 to the firewall. With the threaded portion of #14 removed I had to find another firewall to engine bonding strap place to secure it.

Old spot:

Revised spot with new bonding strap:

Thread

Thread Starter

Forum

Replies

Last Post

Sandyman

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

6

05-01-2016 05:44 PM

flashsplat

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

16

12-13-2015 02:18 PM

lhpdiver

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

1

11-30-2015 02:28 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)