P1694 No CCD message from PCM- Aisin transmission

#1

Senior Member

Thread Starter

Join Date: May 2014

Location: Iroquois Ontario Canada

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

OK I had found a thread, some where, that explained how to check the PCM/TCM, but now I can't find it again

Yesterday after finally finishing up the transmission swap, and brake job I started up my XJ to move it out of the way. It ran like crap and the gauges were all over the place. With a little searching it looked like the problem was the CPS. At the same time a power steering line popped , so I ordered the parts I needed from Napa and picked them up and installed them today. Good news is the engine runs smoothly now and there are no leaks. Bad news is I am still getting the P1694 code

, so I ordered the parts I needed from Napa and picked them up and installed them today. Good news is the engine runs smoothly now and there are no leaks. Bad news is I am still getting the P1694 code Yes I did erase the code and it keeps coming back once I start the Jeep.

Yes I did erase the code and it keeps coming back once I start the Jeep.

I have checked all the extrernal wiring on the transmission and transfer case and everything looks OK. No corrosion and no pinched wires so now it is time to check for a short between the PCM and TCM and can't find what I am looking for.

If anyone knows of such a thread could you point me to it? It had proper instructions, with pictures. A second option would be if you actually know how to do what I want and are willing to explain it to me. I would be forever grateful for the help.

Added information. It is a 1998 Cherokee Sport 4X4 with a AW4 transmission and the replacement transmission came from another 98 Sport

Yesterday after finally finishing up the transmission swap, and brake job I started up my XJ to move it out of the way. It ran like crap and the gauges were all over the place. With a little searching it looked like the problem was the CPS. At the same time a power steering line popped

, so I ordered the parts I needed from Napa and picked them up and installed them today. Good news is the engine runs smoothly now and there are no leaks. Bad news is I am still getting the P1694 code

, so I ordered the parts I needed from Napa and picked them up and installed them today. Good news is the engine runs smoothly now and there are no leaks. Bad news is I am still getting the P1694 code Yes I did erase the code and it keeps coming back once I start the Jeep.

Yes I did erase the code and it keeps coming back once I start the Jeep.I have checked all the extrernal wiring on the transmission and transfer case and everything looks OK. No corrosion and no pinched wires so now it is time to check for a short between the PCM and TCM and can't find what I am looking for.

If anyone knows of such a thread could you point me to it? It had proper instructions, with pictures. A second option would be if you actually know how to do what I want and are willing to explain it to me. I would be forever grateful for the help.

Added information. It is a 1998 Cherokee Sport 4X4 with a AW4 transmission and the replacement transmission came from another 98 Sport

#3

Senior Member

Thread Starter

Join Date: May 2014

Location: Iroquois Ontario Canada

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

Thanks but those are not the thread I was looking for. They did how ever give me something simple to look at, the ground wire from the dipstick. I know mine is kind of cruddy and needs to be cleaned.

I also noticed that CCKen is the person with the most knowledgeable comments in the threads you linked to. If I can't track this down with the information in those threads I might just have to send him a PM for some one on one of him beating me over the head till I get it

I also noticed that CCKen is the person with the most knowledgeable comments in the threads you linked to. If I can't track this down with the information in those threads I might just have to send him a PM for some one on one of him beating me over the head till I get it

#4

Senior Member

Thread Starter

Join Date: May 2014

Location: Iroquois Ontario Canada

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

Nope wasn't the dipstick ground

I have been working long and hard on this thing for the last few weeks trying to get it on the road. I am now 12 days past my deadline ( when I parked my other car for the winter) and this is the last thing that I need to do before the safety check.

I will be honest, with the long hours put in on it and the pain meds I have been taking because of it, I have elbow problems and not a lot of tendon left in my elbows, I have having trouble understanding these simple instructions:

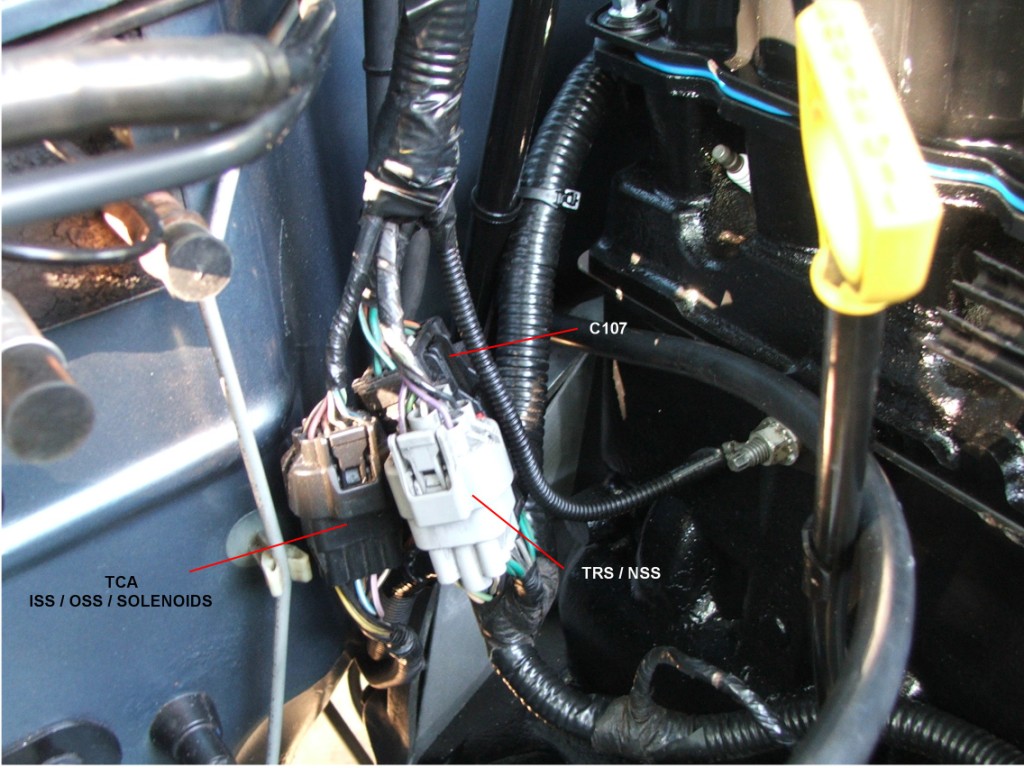

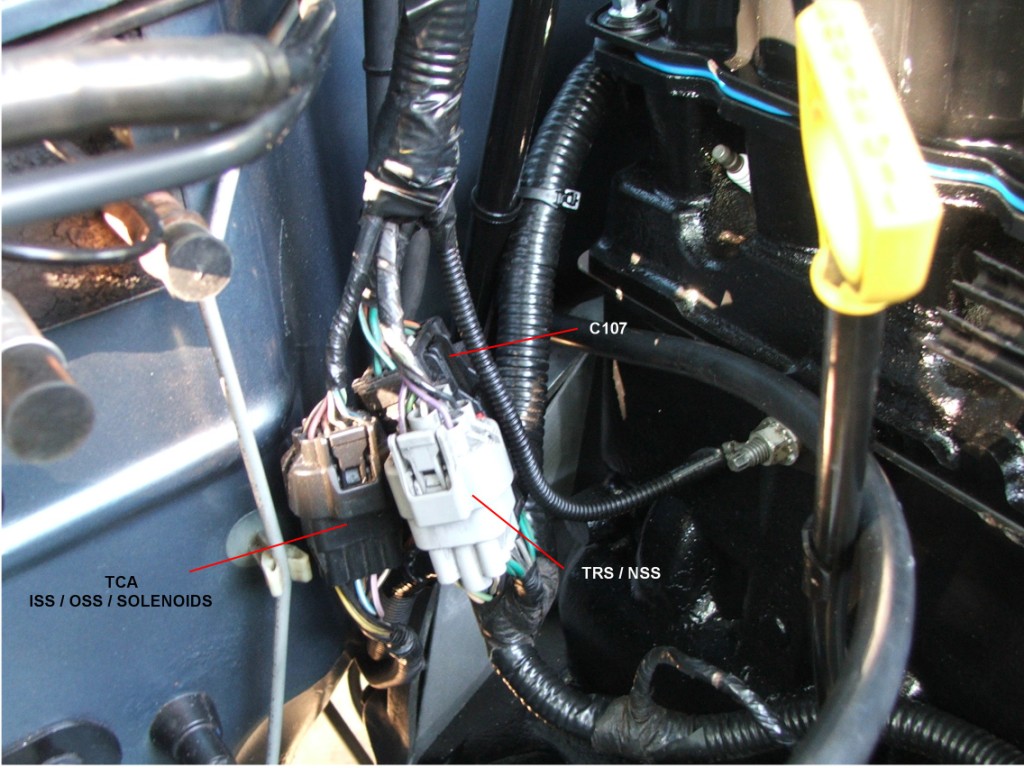

I understand that I am to check between the specified wires on the gray PCM connector and the TCM connector, but where the heck is the TCM connector?

I have been working long and hard on this thing for the last few weeks trying to get it on the road. I am now 12 days past my deadline ( when I parked my other car for the winter) and this is the last thing that I need to do before the safety check.

I will be honest, with the long hours put in on it and the pain meds I have been taking because of it, I have elbow problems and not a lot of tendon left in my elbows, I have having trouble understanding these simple instructions:

DTC P1694 will set if no CCD bus messages are received from PCM for 20 seconds or invalid messages are received for 20 seconds.

Possible Causes

CCD Bus (-) circuit open between PCM and TCM.

CCD Bus (+) circuit open between PCM and TCM.

Transmission CCD bus wiring damaged.

Faulty TCM.

Diagnostic Procedure

1. Using scan tool, clear TCM DTCs. Start engine and let idle for at least 2 minutes. Using scan tool, retrieve TCM DTCs. If DTC P1694 returns, go to next step. If DTC P1694 does not return, go to step 5.

2. Check instrument cluster gauges for proper operation. If fuelgauge and speedometer operate properly, go to next step. If fuel gauge and speedometer do not operate properly, see appropriate INSTRUMENT PANELS article.

3. Turn ignition off. Disconnect Gray PCM harness connector. PCM is located at left front of engine compartment. Disconnect TCM harness connector. Measure resistance of CCD BUS (-) circuit (White/Black wire) between TCM harness connector and Gray PCM harness connector. If resistance is more than 5 ohms, repair open in CCd BUS (-) circuit (White/Black wire). If resistance is 5 ohms or less, go to next step.

4. Measure resistance of CCD BUS (+) circuit (Violet/Brown wire) between TCM harness connector and Gray PCM harness connector. If resistance is more than 5 ohms, repair open in CCd BUS (+) circuit (Violet/Brown wire). If resistance is 5 ohms or less, replace TCM.

5. Conditions necessary to set DTC P1694 are currently not present. Inspect related wiring and harness connectors. See WIRING DIAGRAMS. Repair as necessary. If no problem is found, check for broken, bent, backed-out or corroded terminal pins. Check for chafed, pierced or partially broken wires inside insulation. Repair as necessary.

Possible Causes

CCD Bus (-) circuit open between PCM and TCM.

CCD Bus (+) circuit open between PCM and TCM.

Transmission CCD bus wiring damaged.

Faulty TCM.

Diagnostic Procedure

1. Using scan tool, clear TCM DTCs. Start engine and let idle for at least 2 minutes. Using scan tool, retrieve TCM DTCs. If DTC P1694 returns, go to next step. If DTC P1694 does not return, go to step 5.

2. Check instrument cluster gauges for proper operation. If fuelgauge and speedometer operate properly, go to next step. If fuel gauge and speedometer do not operate properly, see appropriate INSTRUMENT PANELS article.

3. Turn ignition off. Disconnect Gray PCM harness connector. PCM is located at left front of engine compartment. Disconnect TCM harness connector. Measure resistance of CCD BUS (-) circuit (White/Black wire) between TCM harness connector and Gray PCM harness connector. If resistance is more than 5 ohms, repair open in CCd BUS (-) circuit (White/Black wire). If resistance is 5 ohms or less, go to next step.

4. Measure resistance of CCD BUS (+) circuit (Violet/Brown wire) between TCM harness connector and Gray PCM harness connector. If resistance is more than 5 ohms, repair open in CCd BUS (+) circuit (Violet/Brown wire). If resistance is 5 ohms or less, replace TCM.

5. Conditions necessary to set DTC P1694 are currently not present. Inspect related wiring and harness connectors. See WIRING DIAGRAMS. Repair as necessary. If no problem is found, check for broken, bent, backed-out or corroded terminal pins. Check for chafed, pierced or partially broken wires inside insulation. Repair as necessary.

#5

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Why did you change the transmission to begin with?

Open this link and scroll down to post #49. It shows the ground points in the engine bay.

https://www.cherokeeforum.com/f2/gre...e-6558/index4/

Note that the TCM is grounded at G101.

It is essential that G100 is very clean, both the ring terminal and the fender surface. This is the main battery to chassis ground.

There have been a few CEL issues cleared by disassembling, cleaning, and securing these grounds.

Do this first before chasing your tail reading out PCM/TCM wires.

Also, there are transmission connectors near the trans dipstick. If these connectors are loose, corroded, or dirty, or have bent pins, it may cause an issue. Inspect them.

Open this link and scroll down to post #49. It shows the ground points in the engine bay.

https://www.cherokeeforum.com/f2/gre...e-6558/index4/

Note that the TCM is grounded at G101.

It is essential that G100 is very clean, both the ring terminal and the fender surface. This is the main battery to chassis ground.

There have been a few CEL issues cleared by disassembling, cleaning, and securing these grounds.

Do this first before chasing your tail reading out PCM/TCM wires.

Also, there are transmission connectors near the trans dipstick. If these connectors are loose, corroded, or dirty, or have bent pins, it may cause an issue. Inspect them.

Last edited by CCKen; 11-12-2014 at 12:15 PM.

#6

Senior Member

Thread Starter

Join Date: May 2014

Location: Iroquois Ontario Canada

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

I was hoping you would chime in and that i wouldn't have to go harass you for help

I changed the transmission because I broke the threaded part off the manual shift valve shaft while changing a damaged flex plate. Unfortunately that part is not available for purchase anymore with out getting a full used transmission. Since I found a transmission from another 98 Sport it was easier to just put the new used transmission in.

while changing a damaged flex plate. Unfortunately that part is not available for purchase anymore with out getting a full used transmission. Since I found a transmission from another 98 Sport it was easier to just put the new used transmission in.

I am going out to check and clean the rest of the grounds right now. I have already scrubbed and cleaned G102. The firewall to cylinder head strap was badly corroded and I replaced that yesterday. Only problem is that the only strap I could find didn't have a large enough eyelet to go back to the original cylinder head bolt so I put it to the intake manifold where the bracket to the CPS is. Should I go out and buy a larger eyelet and get that strap back to its original location?

I changed the transmission because I broke the threaded part off the manual shift valve shaft

while changing a damaged flex plate. Unfortunately that part is not available for purchase anymore with out getting a full used transmission. Since I found a transmission from another 98 Sport it was easier to just put the new used transmission in.

while changing a damaged flex plate. Unfortunately that part is not available for purchase anymore with out getting a full used transmission. Since I found a transmission from another 98 Sport it was easier to just put the new used transmission in.I am going out to check and clean the rest of the grounds right now. I have already scrubbed and cleaned G102. The firewall to cylinder head strap was badly corroded and I replaced that yesterday. Only problem is that the only strap I could find didn't have a large enough eyelet to go back to the original cylinder head bolt so I put it to the intake manifold where the bracket to the CPS is. Should I go out and buy a larger eyelet and get that strap back to its original location?

#7

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

I was hoping you would chime in and that i wouldn't have to go harass you for help

I changed the transmission because I broke the threaded part off the manual shift valve shaft while changing a damaged flex plate. Unfortunately that part is not available for purchase anymore with out getting a full used transmission. Since I found a transmission from another 98 Sport it was easier to just put the new used transmission in.

while changing a damaged flex plate. Unfortunately that part is not available for purchase anymore with out getting a full used transmission. Since I found a transmission from another 98 Sport it was easier to just put the new used transmission in.

I am going out to check and clean the rest of the grounds right now. I have already scrubbed and cleaned G102. The firewall to cylinder head strap was badly corroded and I replaced that yesterday. Only problem is that the only strap I could find didn't have a large enough eyelet to go back to the original cylinder head bolt so I put it to the intake manifold where the bracket to the CPS is. Should I go out and buy a larger eyelet and get that strap back to its original location?

I changed the transmission because I broke the threaded part off the manual shift valve shaft

while changing a damaged flex plate. Unfortunately that part is not available for purchase anymore with out getting a full used transmission. Since I found a transmission from another 98 Sport it was easier to just put the new used transmission in.

while changing a damaged flex plate. Unfortunately that part is not available for purchase anymore with out getting a full used transmission. Since I found a transmission from another 98 Sport it was easier to just put the new used transmission in.I am going out to check and clean the rest of the grounds right now. I have already scrubbed and cleaned G102. The firewall to cylinder head strap was badly corroded and I replaced that yesterday. Only problem is that the only strap I could find didn't have a large enough eyelet to go back to the original cylinder head bolt so I put it to the intake manifold where the bracket to the CPS is. Should I go out and buy a larger eyelet and get that strap back to its original location?

That firewall to cylinder head bolt is an alternate ground path from the battery to the chassis, via the engine, as well as its intended purpose. If G100 is compromised this alternate ground path is the only link from the battery to the chassis. But if G101 is corroded this path is compromised. Every ground path in the Jeep is important.

Myself, I fabricated a new cable using AWG 8 wire and suitable terminal ends and ran it from the firewall down to the a bellhousing spacer bolt. No radio interference so far.

Trending Topics

#9

Senior Member

Thread Starter

Join Date: May 2014

Location: Iroquois Ontario Canada

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

I reused the original wire harnesses and NSS, I didn't think it was a problem when I started this thread since they have never been cut it was the ones on the replacement transmission that were cut. I did inspect all of the connectors before plugging things together.

The nuts on G101 are so corroded that I can get them off the studs with just wrenches and PB Blaster. The other grounds were good, but I still sanded to shinny metal and applied some dielectric grease.

The nuts on G101 are so corroded that I can get them off the studs with just wrenches and PB Blaster. The other grounds were good, but I still sanded to shinny metal and applied some dielectric grease.

#10

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

I reused the original wire harnesses and NSS, I didn't think it was a problem when I started this thread since they have never been cut it was the ones on the replacement transmission that were cut. I did inspect all of the connectors before plugging things together.

The nuts on G101 are so corroded that I can get them off the studs with just wrenches and PB Blaster. The other grounds were good, but I still sanded to shinny metal and applied some dielectric grease.

The nuts on G101 are so corroded that I can get them off the studs with just wrenches and PB Blaster. The other grounds were good, but I still sanded to shinny metal and applied some dielectric grease.

Those Kepps nuts used on G101 are a ********. Be very careful getting them off. You stand a chance of twisting the ring terminals and the wires. If you can, hold the ring terminals using needle nose pliers while you turn the nuts. Go back on with new 5/16" free spinning washer nuts (Lowe's), not Kepps nuts..

#11

Senior Member

Thread Starter

Join Date: May 2014

Location: Iroquois Ontario Canada

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

There is no chance of getting the nuts off except with maybe a nut breaker. I have tried everything in my arsenal and get the exact same result, everything tries to spin out of the block. The nuts below the ring terminals are rounded and the ones on top have been corroded into some odd size that is not metric or SAE. My rounded bolt/nut removers will grab them, but there is no way to hold the stud from spinning.

I removed the grease and washed things down with electric cleaner then re-installed the grounds I could do, but I fear i did some damage trying to get the grounds off of G101. Before it would start and run smoothly, now as soon as the key is moved to the on position I get a fast ticking noise coming from the front passenger side and it will only turn over with out starting.

For the record all electrical work is done with the battery completely disconnected so I am positive that nothing has been shorted or burned out

I removed the grease and washed things down with electric cleaner then re-installed the grounds I could do, but I fear i did some damage trying to get the grounds off of G101. Before it would start and run smoothly, now as soon as the key is moved to the on position I get a fast ticking noise coming from the front passenger side and it will only turn over with out starting.

For the record all electrical work is done with the battery completely disconnected so I am positive that nothing has been shorted or burned out

#12

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

There is no chance of getting the nuts off except with maybe a nut breaker. I have tried everything in my arsenal and get the exact same result, everything tries to spin out of the block. The nuts below the ring terminals are rounded and the ones on top have been corroded into some odd size that is not metric or SAE. My rounded bolt/nut removers will grab them, but there is no way to hold the stud from spinning.

I removed the grease and washed things down with electric cleaner then re-installed the grounds I could do, but I fear i did some damage trying to get the grounds off of G101. Before it would start and run smoothly, now as soon as the key is moved to the on position I get a fast ticking noise coming from the front passenger side and it will only turn over with out starting.

You'll have to address the G101 connections. You cannot half-vast the job.

For the record all electrical work is done with the battery completely disconnected so I am positive that nothing has been shorted or burned out

I removed the grease and washed things down with electric cleaner then re-installed the grounds I could do, but I fear i did some damage trying to get the grounds off of G101. Before it would start and run smoothly, now as soon as the key is moved to the on position I get a fast ticking noise coming from the front passenger side and it will only turn over with out starting.

You'll have to address the G101 connections. You cannot half-vast the job.

For the record all electrical work is done with the battery completely disconnected so I am positive that nothing has been shorted or burned out

You're not the first person to face this problem.

#13

Senior Member

Thread Starter

Join Date: May 2014

Location: Iroquois Ontario Canada

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

I will give it another go tomorrow, it is dark here now and getting cold. Not that tomorrow is going to be any better, calling for a high of 39 and the temps drop off from there fro the rest of the week and snow by Sunday

If I don't get it solved by tomorrow I will just break down and have it towed to the shop and pay someone else to work on it Saying that really hurts because I have always been one to do my own work

Saying that really hurts because I have always been one to do my own work

I just really need this thing on the road asap. If it hadn't taken 5 weeks for my quarter panels to come it I would have had more time to work on this.

If I don't get it solved by tomorrow I will just break down and have it towed to the shop and pay someone else to work on it

Saying that really hurts because I have always been one to do my own work

Saying that really hurts because I have always been one to do my own work

I just really need this thing on the road asap. If it hadn't taken 5 weeks for my quarter panels to come it I would have had more time to work on this.

#14

Senior Member

Thread Starter

Join Date: May 2014

Location: Iroquois Ontario Canada

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

OK after some PM advice from CCKen , I really need to buy this man a beer or two maybe more if I ever meet him in person, I have managed to get the G101 grounds out. I did have to cut the heaviest ground wire and replace that ring terminal, along with the ring terminals on the 4 smaller wires. I was able to save and clean up the other heavier ground wire.

, I really need to buy this man a beer or two maybe more if I ever meet him in person, I have managed to get the G101 grounds out. I did have to cut the heaviest ground wire and replace that ring terminal, along with the ring terminals on the 4 smaller wires. I was able to save and clean up the other heavier ground wire.

As it sits right now I have all the G101 terminals cleaned up or replaced, the studs that they mount to have been made shiny again, and all the other grounds have been cleaned up. I still need to put G101 back together, along with the wires to the alternator and starter. I took them off so I could get the G101 wires high enough to work on from the top. Right now I am typing this then walking to the other end of town in hopes that the local lumber store has a pair of 5/16-18 nuts to replace the ones that cause the extra work in the first place.

I think I found the cause of the sudden no start too. The two small wires going to the front of G101 had snapped off in my efforts to get things free yesterday. I will find out in about 2 hours, the time it takes me to walk to the store and back, and the time to get everything back together.

, I really need to buy this man a beer or two maybe more if I ever meet him in person, I have managed to get the G101 grounds out. I did have to cut the heaviest ground wire and replace that ring terminal, along with the ring terminals on the 4 smaller wires. I was able to save and clean up the other heavier ground wire.

, I really need to buy this man a beer or two maybe more if I ever meet him in person, I have managed to get the G101 grounds out. I did have to cut the heaviest ground wire and replace that ring terminal, along with the ring terminals on the 4 smaller wires. I was able to save and clean up the other heavier ground wire.As it sits right now I have all the G101 terminals cleaned up or replaced, the studs that they mount to have been made shiny again, and all the other grounds have been cleaned up. I still need to put G101 back together, along with the wires to the alternator and starter. I took them off so I could get the G101 wires high enough to work on from the top. Right now I am typing this then walking to the other end of town in hopes that the local lumber store has a pair of 5/16-18 nuts to replace the ones that cause the extra work in the first place.

I think I found the cause of the sudden no start too. The two small wires going to the front of G101 had snapped off in my efforts to get things free yesterday. I will find out in about 2 hours, the time it takes me to walk to the store and back, and the time to get everything back together.

#15

Senior Member

Thread Starter

Join Date: May 2014

Location: Iroquois Ontario Canada

Posts: 946

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

And it runs again I need to find my scanner now and clear any codes then let it run for a bit and rescan to see what all pops up.

I need to find my scanner now and clear any codes then let it run for a bit and rescan to see what all pops up.

I need to find my scanner now and clear any codes then let it run for a bit and rescan to see what all pops up.

I need to find my scanner now and clear any codes then let it run for a bit and rescan to see what all pops up.