Cherokee Won't Stay Running??

#1

Seasoned Member

Thread Starter

Join Date: Dec 2010

Location: So. California

Posts: 345

Likes: 0

Received 1 Like

on

1 Post

Year: 1991

Model: Cherokee

Engine: 4.0 HO

Just wondering if anyone has ever had this happen on their Jeep.

My nephew (Steven) has a 4.0L 90 XJ that I gave him a little over a year ago. Before I gave it to him I drove it daily for about 2 1/2 years, repairing the usual things as needed. It has been running great since he has had it up until now. The Jeep will start up fine but as soon as the engine drops down to an idle it shuts off. If you keep it reved up it will stay running.

Steven is a good kid but doesn't know a lot about engines so I am trying to help him figure this out. If the Jeep was near by it would be a lot easier for me to troubleshoot things, but he lives in Knoxville TN. and I live in California.

Do you guys have any ideas or know of any common causes for this that I can pass along to him? My first thought was that the coil it going bad.

Any help would be very much appreciated!!!!

Thank you guys!!

Dennis

My nephew (Steven) has a 4.0L 90 XJ that I gave him a little over a year ago. Before I gave it to him I drove it daily for about 2 1/2 years, repairing the usual things as needed. It has been running great since he has had it up until now. The Jeep will start up fine but as soon as the engine drops down to an idle it shuts off. If you keep it reved up it will stay running.

Steven is a good kid but doesn't know a lot about engines so I am trying to help him figure this out. If the Jeep was near by it would be a lot easier for me to troubleshoot things, but he lives in Knoxville TN. and I live in California.

Do you guys have any ideas or know of any common causes for this that I can pass along to him? My first thought was that the coil it going bad.

Any help would be very much appreciated!!!!

Thank you guys!!

Dennis

#2

CF Veteran

Join Date: Sep 2010

Location: Mercer County, NJ

Posts: 12,692

Likes: 0

Received 4 Likes

on

4 Posts

Year: 2001

Model: Cherokee

Engine: 4.0L I6 HO

Originally Posted by AMXJ

Just wondering if anyone has ever had this happen on their Jeep.

My nephew (Steven) has a 4.0L 90 XJ that I gave him a little over a year ago. Before I gave it to him I drove it daily for about 2 1/2 years, repairing the usual things as needed. It has been running great since he has had it up until now. The Jeep will start up fine but as soon as the engine drops down to an idle it shuts off. If you keep it reved up it will stay running.

Steven is a good kid but doesn't know a lot about engines so I am trying to help him figure this out. If the Jeep was near by it would be a lot easier for me to troubleshoot things, but he lives in Knoxville TN. and I live in California.

Do you guys have any ideas or know of any common causes for this that I can pass along to him? My first thought was that the coil it going bad.

Any help would be very much appreciated!!!!

Thank you guys!!

Dennis

My nephew (Steven) has a 4.0L 90 XJ that I gave him a little over a year ago. Before I gave it to him I drove it daily for about 2 1/2 years, repairing the usual things as needed. It has been running great since he has had it up until now. The Jeep will start up fine but as soon as the engine drops down to an idle it shuts off. If you keep it reved up it will stay running.

Steven is a good kid but doesn't know a lot about engines so I am trying to help him figure this out. If the Jeep was near by it would be a lot easier for me to troubleshoot things, but he lives in Knoxville TN. and I live in California.

Do you guys have any ideas or know of any common causes for this that I can pass along to him? My first thought was that the coil it going bad.

Any help would be very much appreciated!!!!

Thank you guys!!

Dennis

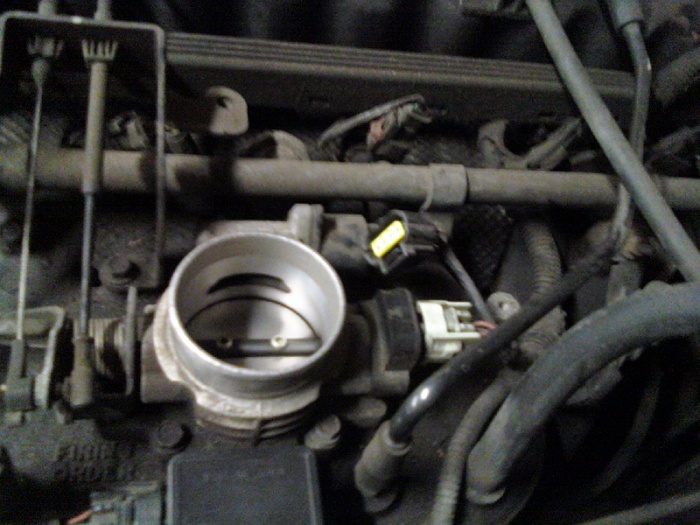

I have an 01 so yours Might be in a different location. If he is t good with cars then maybe a shop should replace it but if he can manage you can clean it with TB cleaner or replace it.

#3

CF Veteran

Join Date: Apr 2010

Location: knoxville, tn

Posts: 3,966

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2000

Model: Cherokee

Engine: 98 4.0 I6

im in knox, I dont know much about the earlier years but could be a number different things...i reccomend gillespie imports...they helped my xj alot when I was in highschool

#4

CF Veteran

Join Date: Nov 2010

Location: In the middle of Minnesota!

Posts: 5,805

Received 99 Likes

on

88 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

1. One of the biggest causes of stalling at idle is a "marginal battery". Have the battery LOAD TESTED at a parts store. It's free and you need to rule this in or out early in the troubleshooting process.And yes, you CAN have a battery that is strong enough to start the engine, but marginal enough to give the engine management system fits and create stalling. It is not at all uncommon.

2. Perform a "freshening" of all engine grounds. RENIX (87-90) are very susceptible to ground issues! More on that below.

3. Be sure tuneup hardware is solid. Fresh Champion copper plugs gapped to 035, new plug wires, distributor cap and rotor and fuel filter.

4. If all of the above is performed and you still have symptoms, I'd recommend a thorough cleaning of both the idle air control and throttle body. And I'd test and adjust the throttle position sensor. More on those two items below.

-------------------------------------------

The Idle Air Control (IAC) is mounted on the back of the throttle body. (front for 87-90) The valve controls the idle speed of the engine by controlling the amount of air flowing through the air control passage. It consists of a stepper motor that moves a pintle shaped plunger in and out of the air control passage. When the valve plunger is moved in, the air control passage flows more air which raises the idle speed. When the valve plunger is moved out, the air control passage flows less air which lowers the idle speed. Over time and miles, the IAC can get carboned up which can have an adverse affect on idle quality. Cleaning the IAC may restore proper function and is an easy procedure to perform and good preventive maintenance so it is never a bad idea.

CLEANING THE JEEP 4.0 IDLE AIR CONTROL

Remove the air filter cover, associated hoses and the rubber boot that goes from the air filter cover to the throttle body. Remove the IAC with a torx driver (2 bolts; one can be kind of hard to get to)

“Gently” wiggle out the IAC from the throttle body. Gasket on the IAC can be re-used if it is not damaged

Clean the IAC with a spray can of throttle body cleaner; inexpensive and available at any place that sells auto parts. Throttle body cleaner is recommended rather than carburetor cleaner as it is less harsh, safe for throttle body coatings and is best for this task. Use cleaner, a rag and a toothbrush and or Q-Tips. Be gentle; don’t twist or pull on the pintle that protrudes from the IAC as it is fragile and you could damage it.

Thoroughly spray clean and flush where the IAC seats in the throttle body with the same spray cleaner

It is also a good idea to clean the entire throttle body itself, the butterfly valve inside of the throttle body and all associated linkage as long as you have things disassembled

Reinstall IAC and check idle quality

-------------------------------------------------

RENIX TPS ADJUSTMENT

Before attempting to adjust your TPS be sure the throttle body has been recently cleaned.

It's especially important that the edges of the throttle butterfly are free of any carbon build-up.

IMPORTANT NOTE: Using one lead of your ohmmeter, probe the B terminal of the flat 3 wire connector

of the TPS . The letters are embossed on the connector itself.

Touch the other lead of your meter to the negative battery post.

If you see more than 1 ohm of resistance some modifications to the sensor ground harness will be

necessary. The harness repair must be performed before proceeding.

I can provide an instruction sheet for that if needed.

MANUAL TRANSMISSION:

RENIX manual transmission equipped XJs have a three-wire TPS mounted on the throttle body.

This manual transmission vehicle TPS provides data input to the ECU. The manual transmission

TPS has three wires in the connector and they're clearly embossed with the letters A,B, and C.

Wire "A" is positive.

Wire "B" is ground.

Key ON, measure voltage from "A" positive to "B" ground by back-probing the connectors..

Note the voltage reading--this is your REFERENCE voltage.

Key ON, back-probe the connector at wires "B" and "C". Measure the voltage. This is your

OUTPUT voltage.

Your OUTPUT voltage needs to be seventeen percent of your REFERENCE voltage. For

example: 4.82 volts X .17=.82 volts. Adjust the TPS until you have achieved this percentage. If

you can't achieve the correct output voltage replace the TPS and start over.

AUTOMATIC TRANSMISSION:

RENIX automatic transmission equipped XJs have a TPS with two connectors. There is a three-

wire connector, same as the manual transmission vehicles have, and it is tested the same as the

manual transmission equipped vehicles--FOR ENGINE MANAGEMENT RELATED ISSUES.

However, the automatic TPS also has a four-wire connector clearly embossed with the letters

A,B,C, and D.. For the automatic transmission equipped vehicles the four-wire connector

provides data to the TCU.

Key ON, measure voltage between "A" positive and "D" ground. Note the voltage. This is your

REFERENCE voltage.

Back-probe the connector at wires "B" and "D". Measure the voltage. This is your OUTPUT

voltage. Your OUTPUT voltage needs to be eighty-three percent of your REFERENCE voltage.

For example 4.8 volts X .83=3.98 volts. Adjust the TPS until you have achieved this percentage.

If you can't, replace the TPS and start over.

So, if you have an automatic equipped XJ your TPS has two sides--one side feeds the ECU, and

the other side feeds the TCU. If you have TRANSMISSION issues check the four-wire

connector side of the TPS. If you have ENGINE issues check the three-wire connector side of

the TPS.

For those with a MANUAL TRANSMISSION--the TPS for the manual transmission XJs is

stupid expensive. You can substitute the automatic transmission TPS which is reasonably priced.

-------------------------------------

Renix Ground Refreshing

The Renix era XJs and MJs were built with an under-engineered grounding system for the engine/transmission electronics. One problem in particular involves the multiple ground connection at the engine dipstick tube stud. A poor ground here can cause a multitude of driveabililty issues, wasted time, and wasted money replacing unnecessary components.

The components grounding at the dipstick tube stud are:

Distributor Sync Sensor, TCU main ground, TCU “Shift Point Logic”, Ignition control Module, Injectors, ECU main ground which other engine sensors ground through, Oxygen sensor, Knock Sensor, Cruise Control, and Transmission Sync signal. All extremely important stuff.

The factory was aware of the issues with this ground point and addressed it by suggesting the following:

Remove the nut holding the wire terminals to the stud. Verify that the stud is indeed tightened securely into the block. Scrape any and all paint from the stud’s mounting surface where the wires will attach. Must be clean, shiny and free of any oil, grease, or paint.

Inspect the wire terminals. Check to see that none of the terminals are crimped over wire insulation instead of bare wire. Be sure the crimps are tight. It wouldn’t hurt to re-crimp them just as a matter of course. Sand and polish the wire terminals until clean and shiny on both sides. Reinstall all the wires to the stud and tighten the nut down securely.

While you’re in that general area, locate the battery negative cable which is fastened to the engine block just forward of the dipstick stud. Remove the bolt, scrape the block to bare metal, clean and polish the cable terminal, and reattach securely.

Another area where the grounding system on Renix era Jeeps was lacking is the engine to chassis ground. There is a braided cable from the back of the cylinder head that also attaches to the driver’s side of the firewall. This cable is undersized for it’s intended use and subject to corrosion and poor connections at each end.

First off, remove the cable end from the firewall using a 15mm wrench or socket. Scrape the paint off down to bare metal and clean the wire terminal. Reattach securely.

Remove the other end of the cable from the rear of the head using a 3’4” socket. Clean all the oil, paint and crud from the stud. Clean the wire terminal of the cable and reattach securely.

A suggestion regarding the braided cable:

I prefer to add a #4 Gauge cable from the firewall to a bolt on the rear of the intake manifold, either to a heat shield bolt or fuel rail bolt. A cable about 18” long with a 3/8” lug on each end works great and you can get one at any parts store already made up. Napa has them as part number 781116.

A further improvement to the grounding system can be made using a #4 cable, about 10” long with 3/8” terminals at each end. Attach one end of this cable to the negative battery bolt and the other end under the closest 10mm headed bolt on the radiator support just forward of the battery. Napa part number 781115.

If you want to upgrade your grounds and battery cables in general, contact Jon at www.kelleyswip.com. He makes an incredible cable upgrade for a very reasonable price.

2. Perform a "freshening" of all engine grounds. RENIX (87-90) are very susceptible to ground issues! More on that below.

3. Be sure tuneup hardware is solid. Fresh Champion copper plugs gapped to 035, new plug wires, distributor cap and rotor and fuel filter.

4. If all of the above is performed and you still have symptoms, I'd recommend a thorough cleaning of both the idle air control and throttle body. And I'd test and adjust the throttle position sensor. More on those two items below.

-------------------------------------------

The Idle Air Control (IAC) is mounted on the back of the throttle body. (front for 87-90) The valve controls the idle speed of the engine by controlling the amount of air flowing through the air control passage. It consists of a stepper motor that moves a pintle shaped plunger in and out of the air control passage. When the valve plunger is moved in, the air control passage flows more air which raises the idle speed. When the valve plunger is moved out, the air control passage flows less air which lowers the idle speed. Over time and miles, the IAC can get carboned up which can have an adverse affect on idle quality. Cleaning the IAC may restore proper function and is an easy procedure to perform and good preventive maintenance so it is never a bad idea.

CLEANING THE JEEP 4.0 IDLE AIR CONTROL

Remove the air filter cover, associated hoses and the rubber boot that goes from the air filter cover to the throttle body. Remove the IAC with a torx driver (2 bolts; one can be kind of hard to get to)

“Gently” wiggle out the IAC from the throttle body. Gasket on the IAC can be re-used if it is not damaged

Clean the IAC with a spray can of throttle body cleaner; inexpensive and available at any place that sells auto parts. Throttle body cleaner is recommended rather than carburetor cleaner as it is less harsh, safe for throttle body coatings and is best for this task. Use cleaner, a rag and a toothbrush and or Q-Tips. Be gentle; don’t twist or pull on the pintle that protrudes from the IAC as it is fragile and you could damage it.

Thoroughly spray clean and flush where the IAC seats in the throttle body with the same spray cleaner

It is also a good idea to clean the entire throttle body itself, the butterfly valve inside of the throttle body and all associated linkage as long as you have things disassembled

Reinstall IAC and check idle quality

-------------------------------------------------

RENIX TPS ADJUSTMENT

Before attempting to adjust your TPS be sure the throttle body has been recently cleaned.

It's especially important that the edges of the throttle butterfly are free of any carbon build-up.

IMPORTANT NOTE: Using one lead of your ohmmeter, probe the B terminal of the flat 3 wire connector

of the TPS . The letters are embossed on the connector itself.

Touch the other lead of your meter to the negative battery post.

If you see more than 1 ohm of resistance some modifications to the sensor ground harness will be

necessary. The harness repair must be performed before proceeding.

I can provide an instruction sheet for that if needed.

MANUAL TRANSMISSION:

RENIX manual transmission equipped XJs have a three-wire TPS mounted on the throttle body.

This manual transmission vehicle TPS provides data input to the ECU. The manual transmission

TPS has three wires in the connector and they're clearly embossed with the letters A,B, and C.

Wire "A" is positive.

Wire "B" is ground.

Key ON, measure voltage from "A" positive to "B" ground by back-probing the connectors..

Note the voltage reading--this is your REFERENCE voltage.

Key ON, back-probe the connector at wires "B" and "C". Measure the voltage. This is your

OUTPUT voltage.

Your OUTPUT voltage needs to be seventeen percent of your REFERENCE voltage. For

example: 4.82 volts X .17=.82 volts. Adjust the TPS until you have achieved this percentage. If

you can't achieve the correct output voltage replace the TPS and start over.

AUTOMATIC TRANSMISSION:

RENIX automatic transmission equipped XJs have a TPS with two connectors. There is a three-

wire connector, same as the manual transmission vehicles have, and it is tested the same as the

manual transmission equipped vehicles--FOR ENGINE MANAGEMENT RELATED ISSUES.

However, the automatic TPS also has a four-wire connector clearly embossed with the letters

A,B,C, and D.. For the automatic transmission equipped vehicles the four-wire connector

provides data to the TCU.

Key ON, measure voltage between "A" positive and "D" ground. Note the voltage. This is your

REFERENCE voltage.

Back-probe the connector at wires "B" and "D". Measure the voltage. This is your OUTPUT

voltage. Your OUTPUT voltage needs to be eighty-three percent of your REFERENCE voltage.

For example 4.8 volts X .83=3.98 volts. Adjust the TPS until you have achieved this percentage.

If you can't, replace the TPS and start over.

So, if you have an automatic equipped XJ your TPS has two sides--one side feeds the ECU, and

the other side feeds the TCU. If you have TRANSMISSION issues check the four-wire

connector side of the TPS. If you have ENGINE issues check the three-wire connector side of

the TPS.

For those with a MANUAL TRANSMISSION--the TPS for the manual transmission XJs is

stupid expensive. You can substitute the automatic transmission TPS which is reasonably priced.

-------------------------------------

Renix Ground Refreshing

The Renix era XJs and MJs were built with an under-engineered grounding system for the engine/transmission electronics. One problem in particular involves the multiple ground connection at the engine dipstick tube stud. A poor ground here can cause a multitude of driveabililty issues, wasted time, and wasted money replacing unnecessary components.

The components grounding at the dipstick tube stud are:

Distributor Sync Sensor, TCU main ground, TCU “Shift Point Logic”, Ignition control Module, Injectors, ECU main ground which other engine sensors ground through, Oxygen sensor, Knock Sensor, Cruise Control, and Transmission Sync signal. All extremely important stuff.

The factory was aware of the issues with this ground point and addressed it by suggesting the following:

Remove the nut holding the wire terminals to the stud. Verify that the stud is indeed tightened securely into the block. Scrape any and all paint from the stud’s mounting surface where the wires will attach. Must be clean, shiny and free of any oil, grease, or paint.

Inspect the wire terminals. Check to see that none of the terminals are crimped over wire insulation instead of bare wire. Be sure the crimps are tight. It wouldn’t hurt to re-crimp them just as a matter of course. Sand and polish the wire terminals until clean and shiny on both sides. Reinstall all the wires to the stud and tighten the nut down securely.

While you’re in that general area, locate the battery negative cable which is fastened to the engine block just forward of the dipstick stud. Remove the bolt, scrape the block to bare metal, clean and polish the cable terminal, and reattach securely.

Another area where the grounding system on Renix era Jeeps was lacking is the engine to chassis ground. There is a braided cable from the back of the cylinder head that also attaches to the driver’s side of the firewall. This cable is undersized for it’s intended use and subject to corrosion and poor connections at each end.

First off, remove the cable end from the firewall using a 15mm wrench or socket. Scrape the paint off down to bare metal and clean the wire terminal. Reattach securely.

Remove the other end of the cable from the rear of the head using a 3’4” socket. Clean all the oil, paint and crud from the stud. Clean the wire terminal of the cable and reattach securely.

A suggestion regarding the braided cable:

I prefer to add a #4 Gauge cable from the firewall to a bolt on the rear of the intake manifold, either to a heat shield bolt or fuel rail bolt. A cable about 18” long with a 3/8” lug on each end works great and you can get one at any parts store already made up. Napa has them as part number 781116.

A further improvement to the grounding system can be made using a #4 cable, about 10” long with 3/8” terminals at each end. Attach one end of this cable to the negative battery bolt and the other end under the closest 10mm headed bolt on the radiator support just forward of the battery. Napa part number 781115.

If you want to upgrade your grounds and battery cables in general, contact Jon at www.kelleyswip.com. He makes an incredible cable upgrade for a very reasonable price.

Last edited by tjwalker; 01-23-2012 at 07:37 AM.

#5

Seasoned Member

Thread Starter

Join Date: Dec 2010

Location: So. California

Posts: 345

Likes: 0

Received 1 Like

on

1 Post

Year: 1991

Model: Cherokee

Engine: 4.0 HO

Sycoglitch: Thanks for the input! I'll pass that along to him.

Jomps: I'll pass the name of that shop along to him, but right now I know money is tight for him so he is trying to do this himself if possible.

TJWalker: That is a lot of great information and ideas. I'll finish reading through it and have him check these things.

Here is a little background on the Jeep:

Right before giving Steven the Jeep I replaced the battery (new NAPA), battery cables, I cleaned, repaired and secured all of the grounds on the car, replaced spark plugs (Autolite platinum), wires, cap and rotor, air filter, and alternator, along with a lot of unrelated other worn parts. I'll have him go over the grounds and take the battery to get tested as it could be a bad one.

It sounds like the next things to check into will be the IAC and the TPS.

I really appreciate you guys helping us with this problem!!!!!!

Dennis

Jomps: I'll pass the name of that shop along to him, but right now I know money is tight for him so he is trying to do this himself if possible.

TJWalker: That is a lot of great information and ideas. I'll finish reading through it and have him check these things.

Here is a little background on the Jeep:

Right before giving Steven the Jeep I replaced the battery (new NAPA), battery cables, I cleaned, repaired and secured all of the grounds on the car, replaced spark plugs (Autolite platinum), wires, cap and rotor, air filter, and alternator, along with a lot of unrelated other worn parts. I'll have him go over the grounds and take the battery to get tested as it could be a bad one.

It sounds like the next things to check into will be the IAC and the TPS.

I really appreciate you guys helping us with this problem!!!!!!

Dennis

#6

Seasoned Member

Join Date: Jan 2012

Location: Massachusetts, southeast

Posts: 433

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1992

Model: Cherokee

Engine: 4.0L, brown dog mounts, spectre cowl intake, 10 series flowmaster

i had a similar problem with my 92 cherokee. it would start up but then start running iratic and shut off. it ended up being a ballast resistor for the fuel pump. its a white creramic looking thing with two wires going into it bolted to the drivers fender right under the hood. mine was broken into two pieces. all i did was by pass it with a piece of wire and now it runs as good as new.

the purpose of the resistor is to quiet down the fuel pump so by passing it isnt gonna hurt anything. i cant hear a difference in fuel pump noise either.

the purpose of the resistor is to quiet down the fuel pump so by passing it isnt gonna hurt anything. i cant hear a difference in fuel pump noise either.

Last edited by justin92xj; 01-23-2012 at 09:42 PM.

#7

Seasoned Member

Thread Starter

Join Date: Dec 2010

Location: So. California

Posts: 345

Likes: 0

Received 1 Like

on

1 Post

Year: 1991

Model: Cherokee

Engine: 4.0 HO

i had a similar problem with my 92 cherokee. it would start up but then start running iratic and shut off. it ended up being a ballast resistor for the fuel pump. its a white creramic looking thing with two wires going into it bolted to the drivers fender right under the hood. mine was broken into two pieces. all i did was by pass it with a piece of wire and now it runs as good as new.

the purpose of the resistor is to quiet down the fuel pump so by passing it isnt gonna hurt anything. i cant hear a difference in fuel pump noise either.

the purpose of the resistor is to quiet down the fuel pump so by passing it isnt gonna hurt anything. i cant hear a difference in fuel pump noise either.

Thank you again Justin, I hope I can return the favor someday!

Dennis

Thread

Thread Starter

Forum

Replies

Last Post

seansr

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

12

11-15-2022 06:08 AM

zumer715

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

18

07-08-2022 05:17 PM

Gtrsrlly

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

5

08-25-2015 11:50 AM

Brynjaminjones

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

2

08-22-2015 05:01 AM

schaferjeep

Stock Grand Cherokee Tech. All ZJ/WJ/WK Non-modified/stock questions go here!

5

08-21-2015 08:40 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)