Thinkin of welding my spider gears. Any thoughts?

#46

CF Veteran

Join Date: Sep 2009

Location: Summerville, Ga

Posts: 6,322

Likes: 0

Received 5 Likes

on

5 Posts

Year: 1995

Model: Cherokee

Engine: 2.5 4 cyl.

#47

Seasoned Member

Join Date: Jun 2010

Location: Central Washington

Posts: 360

Likes: 0

Received 0 Likes

on

0 Posts

Year: 91 xj, 93 xj, 93 zj, 94 zj

Model: Cherokee

Engine: 2x I6, 2x v8

Still, of all the options, the d35 has the smallest shafts, tubes, AND ring gear of all the axles under XJs, therefore the most breakage and the worst rap. I just wish there was as much support for the 8.25 as the d35 or there would be no reason to keep one around.

#48

Thx guys for all the imput. Ill keep it all in mind. And as for down the road i have an ear to the ground for a 8.25, but ill probly be pulling and 8.8 at the jy this summer when my jeep can have alittle down time. But for the time being ill probly wait to weld up my 35 tell i can find an extra axle shaft to thro in the back of the jeep to take up to the trails with me. Im pretty confident in my welding abilitys. And i know that it all comes down to the axle strength. If i break an axle ill just have to take the timw to swap in the extra. And then ill know for sure then strength of the 35 and will have an great excuse to bring home a 8.8 or 8.25. But i dont plan on putting any money into my 35, just weld up the gears and rock it tell it breaks and upgrade.

But thx everyone for their input! I think ive made my decission to weld

It up, but not tell i get an extra shaft.

But thx everyone for their input! I think ive made my decission to weld

It up, but not tell i get an extra shaft.

#49

Seasoned Member

Join Date: Jun 2009

Location: Lancaster PA

Posts: 298

Likes: 0

Received 2 Likes

on

2 Posts

Year: 1988

Model: Cherokee

Engine: 4.0

welded my dana 35 up tonight. works pretty good the chirping and tires hopping around corners is gonna take some time to get use to. Time will tell of how it holds up

#50

Seasoned Member

Thread Starter

Join Date: Jun 2011

Location: in a small town named ...

Posts: 386

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0L

Originally Posted by 1988cherokee

welded my dana 35 up tonight. works pretty good the chirping and tires hopping around corners is gonna take some time to get use to. Time will tell of how it holds up

#53

I know this may be slightly off topic, but can any explain why the dana 35 in my 1992 xj has much larger axle tube dia. Then my buddies comanche and his 87 (i think) cherokee's dana 35? The tube on mine is the same dia. All the way from centure to outer backing plate, while his almost seem to get smaller the farther out from the centure. But slightly larger at outer end the the centure on the tube, (not centure of axle) if this makes any sense.....

I was just wondering why they are diffrent. Any info would be cool. Thx

I was just wondering why they are diffrent. Any info would be cool. Thx

#55

Seasoned Member

Join Date: Jun 2010

Location: Central Washington

Posts: 360

Likes: 0

Received 0 Likes

on

0 Posts

Year: 91 xj, 93 xj, 93 zj, 94 zj

Model: Cherokee

Engine: 2x I6, 2x v8

I know this may be slightly off topic, but can any explain why the dana 35 in my 1992 xj has much larger axle tube dia. Then my buddies comanche and his 87 (i think) cherokee's dana 35? The tube on mine is the same dia. All the way from centure to outer backing plate, while his almost seem to get smaller the farther out from the centure. But slightly larger at outer end the the centure on the tube, (not centure of axle) if this makes any sense.....

I was just wondering why they are diffrent. Any info would be cool. Thx

I was just wondering why they are diffrent. Any info would be cool. Thx

I would.suspect you have an 8.25, the tubes are larger.

#56

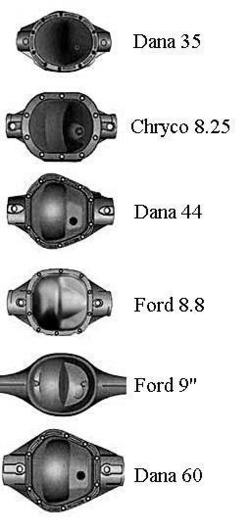

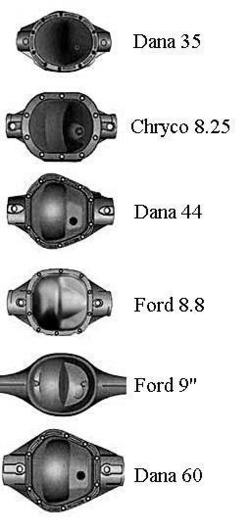

Trollhammer, i found this picture awhile back online,

And my axle centure looks more like the dana 35 then the 8.25.... But my jeeps axle does have deffinitly visable larger axle tubes. I would be extaticaly happy if i have the 8.25. Is there a way to tell for sure? If i pull the cover maybe..?

My jeep is a 1992 cherokee laredo, with the auto trans, and the HP 4.0, and the np231 tc. If any other info would help to figure out if it may have the 8.25. I would appreciate any help i can get or info to solve this question. I can post a pic of the axle housing if someone thinks they could

Tell by pic.

Thx

And my axle centure looks more like the dana 35 then the 8.25.... But my jeeps axle does have deffinitly visable larger axle tubes. I would be extaticaly happy if i have the 8.25. Is there a way to tell for sure? If i pull the cover maybe..?

My jeep is a 1992 cherokee laredo, with the auto trans, and the HP 4.0, and the np231 tc. If any other info would help to figure out if it may have the 8.25. I would appreciate any help i can get or info to solve this question. I can post a pic of the axle housing if someone thinks they could

Tell by pic.

Thx

#59

Ok trollhammer, i looked closly at my axle and i think i do have the 8.25 it has the chrysler emblem, and it has (a rough measurment) of 3 inch dia. Tubes. And i looked up some pics if both types of axles and it looks exaclty like almost every picture i found of the 8.25. The dana 35's look like they have a much rounder cover. While mine is rather olvel, with an almost flat bottom and top. Is there a way to compare the numbers on it to see if it is the 29 splin or the 27.

And now that i know i have a 8.25 whats ur opion on welding up the dif in that? I hear they are much much much stronger then the dana 35, even the 27 splin. So would u say im safer off with welding

It up now?

And now that i know i have a 8.25 whats ur opion on welding up the dif in that? I hear they are much much much stronger then the dana 35, even the 27 splin. So would u say im safer off with welding

It up now?

#60

Seasoned Member

Join Date: Jun 2009

Location: Lancaster PA

Posts: 298

Likes: 0

Received 2 Likes

on

2 Posts

Year: 1988

Model: Cherokee

Engine: 4.0

I welded the spiders together in each corner really good then I welded the spiders to the carrier If you do it just take your time and let it cool down. I had an extra housing laying around so I just put my carrier in that housing and slid the other axles I had laying around into the side gears so the spiders stayed centered If need be when I get some time I can write up a how to with pictures I have extra carriers laying around I can weld up to show you