rear shock relocation

#1

CF Veteran

Thread Starter

Join Date: Jul 2011

Location: northlake IL

Posts: 1,411

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0 I6

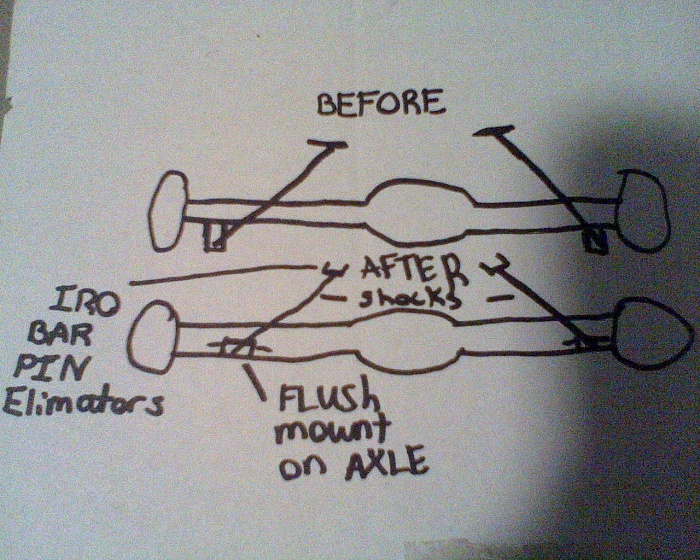

so today as i pulled out of my driveway i heard a pop so i went about my business thinking nothing of it and when i got home ( didnt even drive a mile) i started doing stuff and thought to check on my broken shock mount that the PO welded and did a s@@t job well here you go

so what i am looking to do about this is get these for the shock were it conects to the body i am going with the 1.5 in ones

http://detoursusa.com/xjstm.php

then i want to do this but with the cut part flush with the axle bottom like the pic down on the second page

https://www.cherokeeforum.com/f58/re...arance-105013/

and then to get new shocks i am going with the rc 9000 series

so anyone with any input on this please help i don't know really anything much about shock relocation i know there is a happy medium between were i can go with travel and size of shock

so what i am looking to do about this is get these for the shock were it conects to the body i am going with the 1.5 in ones

http://detoursusa.com/xjstm.php

then i want to do this but with the cut part flush with the axle bottom like the pic down on the second page

https://www.cherokeeforum.com/f58/re...arance-105013/

and then to get new shocks i am going with the rc 9000 series

so anyone with any input on this please help i don't know really anything much about shock relocation i know there is a happy medium between were i can go with travel and size of shock

#2

CF Veteran

Thread Starter

Join Date: Jul 2011

Location: northlake IL

Posts: 1,411

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0 I6

or may do this for the top to have more shock its less of a drop

http://www.ironrockoffroad.com/Merch..._Code=IR-SBPEK

http://www.ironrockoffroad.com/Merch..._Code=IR-SBPEK

#3

CF Veteran

Join Date: Oct 2011

Location: Hudsonville, MI

Posts: 1,630

Likes: 0

Received 3 Likes

on

2 Posts

Year: 1986

Model: Cherokee

Engine: 5.0

I used these bar pin eliminators. Knock out the bar pin and put the new sleeve in and install the shocks.

http://zoneoffroad.com/product-acc?ki=92&gr=1

http://zoneoffroad.com/product-acc?ki=92&gr=1

#4

CF Veteran

Thread Starter

Join Date: Jul 2011

Location: northlake IL

Posts: 1,411

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0 I6

so no one else has any ideas i took out my rear leaf blocks today they were a temp fix for leveling out the jeep going with 2'' shackles this coming week. as of now the axle is held to the jeep by its e brake and brake line

#5

CF Veteran

Join Date: Dec 2010

Location: Frankfort IL

Posts: 1,385

Likes: 0

Received 1 Like

on

1 Post

Year: 2000

Model: Cherokee

Engine: 4.0

This is what I did: Remove the carpet in the hatch, I cut square flaps into the floor around the shock mount leaving one side of the square not cut, that way it opens and closes. Then drilled through the bolt holes and I am using nuts and bolts instead to mount the shock. Next time I have to replace a shock I just lift the carpet to access the bolts. With the carpet over it you cannot tell its even cut. Lowering the shock mount sucks in my opinion as you have to use a shorter shock because with the new setup it will bottom out 1.5in sooner. people go through the floor and build mounts to use longer shocks, not the other way around. Same thing with th lower. I would like to relocate it too but that would make me have to use a shorter shock or bumpstop sooner and I rather just sacrifice some ground clearence then do either of those things.

#6

CF Veteran

Join Date: Jun 2009

Location: Columbus, Ohio

Posts: 2,173

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0, comp cam, 99 intake, apn header, neon injectors, Thunderbolt 2.5" High Flow Cat

whao, put down the cutoff wheel! this one is simple! Go ahead and use the bar pin eliminator, but to bolt it in, do this... get your air hammer out, or a sledge with a center punch and hit the ends of the broken bolts to knock them out, leaving you with holes where the bolts were. Get new bolts, reach through the BIG TRIANGLE HOLES already THERE, and drop the bolts through the holes, put your bar pin eliminators up there, and put nuts on the bolts. Tighten em down, problem solved, took you all of 20 minutes, and you didn't have to go all michael meyers on your jeep with a cutoff wheel.

#7

Trending Topics

#8

CF Veteran

Join Date: Dec 2010

Location: Frankfort IL

Posts: 1,385

Likes: 0

Received 1 Like

on

1 Post

Year: 2000

Model: Cherokee

Engine: 4.0

whao, put down the cutoff wheel! this one is simple! Go ahead and use the bar pin eliminator, but to bolt it in, do this... get your air hammer out, or a sledge with a center punch and hit the ends of the broken bolts to knock them out, leaving you with holes where the bolts were. Get new bolts, reach through the BIG TRIANGLE HOLES already THERE, and drop the bolts through the holes, put your bar pin eliminators up there, and put nuts on the bolts. Tighten em down, problem solved, took you all of 20 minutes, and you didn't have to go all michael meyers on your jeep with a cutoff wheel.

#9

just punch the nuts off then run regular nuts and bolts.

works mint, takes no time to do, doesn't cost you anything.

you might need new bar pins or clean off all the booger welds, but those can be had cheap.

works mint, takes no time to do, doesn't cost you anything.

you might need new bar pins or clean off all the booger welds, but those can be had cheap.

#10

CF Veteran

Thread Starter

Join Date: Jul 2011

Location: northlake IL

Posts: 1,411

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0 I6

for one i not cutting open my floor bc i have no carpet in it it is bedlined and i am putting in a false floor so it wouldnt help. i am looking at the ones in the second post from iron rock i didn't do too much research when i posted this and i am still on the fence about the bottom mount. i have a good idea of what i want to do but i may do what the guy did in his post above on the link but move it to the inside about an inch from the u bolt and flush with the bottom of the axle and then weld tabs on eather side to support it and then put a plate on the bottom of the bracket. it sounds like alot but i have everything already measured just not cut yet i wanted to see what you guys will say about this idea.

Last edited by smeltmaster1; 09-17-2012 at 06:53 PM.

#11

for one i not cutting open my floor bc i have no carpet in it it is bedlined and i am putting in a false floor so it wouldnt help and i am looking at the ones in the second post no from iron rock i didn't do too much research when i posted this and i am still on the fence about the bottom mount i have a good idea of what i want to do and but i may do what the guy did in his but move it to the inside about an inch from the u bolt and flush with the bottom of the axle and then weld tabs on eather side to support it and then put a plate on the bottom of the bracket it sounds like alot but i have everything already measured just not cut yet i wanted to see what you guys will say about this idea

until then, what I said is a commonly accepted and easy to do method to fix the issue you are having.

#12

CF Veteran

Thread Starter

Join Date: Jul 2011

Location: northlake IL

Posts: 1,411

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0 I6

i am set on doing the tops with the IRO bracket and now i am looking for advice on the bottom bracket connected to the axle.

if you understand what i am talking about. the mount is 3 inchs long if you cut it at 2 inches and form the axle round shape on the cut piece and place it about 1-2 inches to the inside of the original mount weld it. then make gussets on each side to give it strength and add a bottom plate to keep it from catching stuff. now on the rear axle there is nothing lower then the diff that will catch anything and you can still have about the same amount of travel up and down

#13

CF Veteran

Thread Starter

Join Date: Jul 2011

Location: northlake IL

Posts: 1,411

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0 I6

#14

CF Veteran

Join Date: Oct 2010

Location: Ontario, Canada

Posts: 2,150

Likes: 0

Received 12 Likes

on

9 Posts

Year: 1989 Laredo

Model: Cherokee

Engine: 4.0 L 6 Renix

Cut your way in weld your way out, rear lower shock mounts, cut off with circular disc, raised and rewelded. In one pic you can see how much was cut back from the sides of the mount. Take your time, use jackstands, clean your areas prior to weld. Reduced snags on the axle.

#15

CF Veteran

Thread Starter

Join Date: Jul 2011

Location: northlake IL

Posts: 1,411

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0 I6

i am going to get all the measurements tomorrow on shock height and where the mounts will actually be. if i can get the axle mounted to the jeep again started raining on me today