Transmission will not mount back to Engine

#1

Junior Member

Thread Starter

Join Date: Feb 2012

Location: Englewood!

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1994

Model: Cherokee

Engine: 4.0

Hello all,

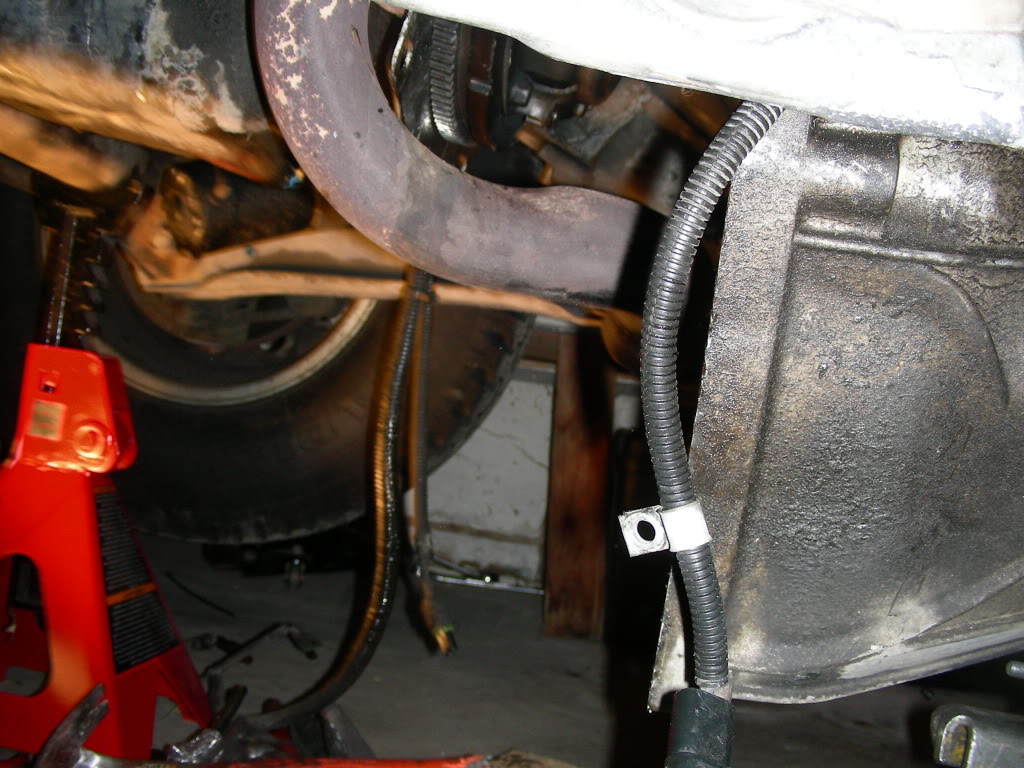

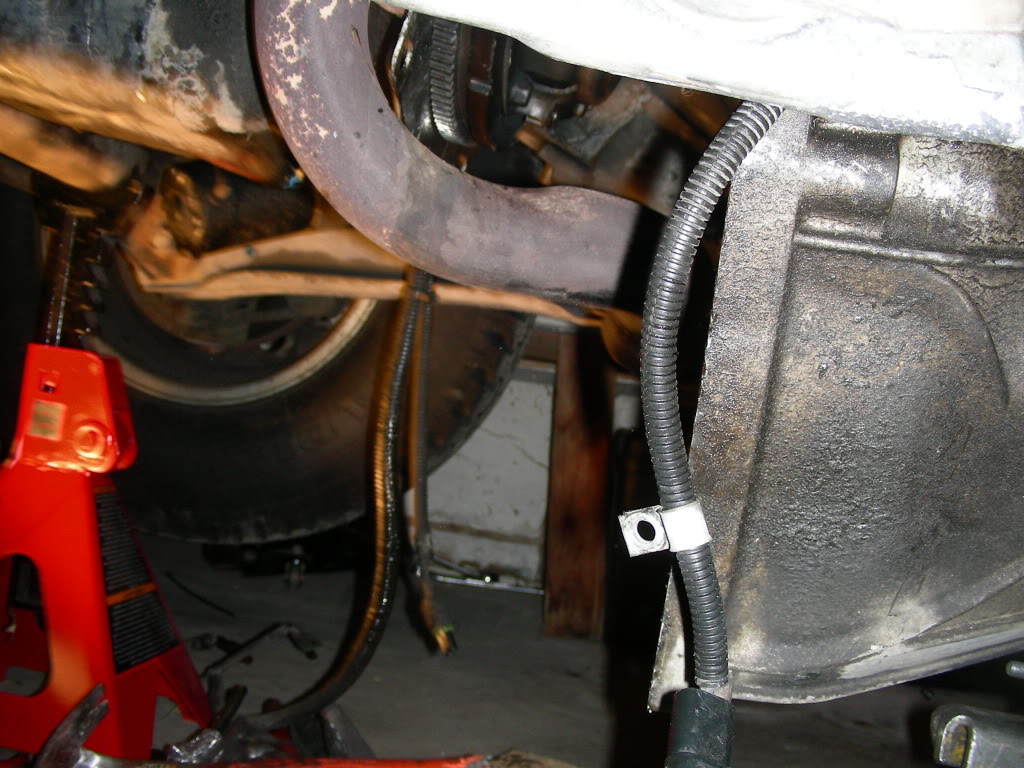

Thank you for reading this. I am having a transmission problem. I pulled my AX15 to put a new seal in. I have been trying to put it back into the engine but nothing will work. I have a transmission jack. No clutch work was done so the pillot bearing should still be centered. Is it possible for the clutch pate to move if it was not removed?

I removed the bell housing and tried to line up the splines without it on and after several hours I couldn't get the input shaft to go into the pilog bearing.

(Exaust was moved out of the way)

Here are some pics of my work.....

Thank you for reading this. I am having a transmission problem. I pulled my AX15 to put a new seal in. I have been trying to put it back into the engine but nothing will work. I have a transmission jack. No clutch work was done so the pillot bearing should still be centered. Is it possible for the clutch pate to move if it was not removed?

I removed the bell housing and tried to line up the splines without it on and after several hours I couldn't get the input shaft to go into the pilog bearing.

(Exaust was moved out of the way)

Here are some pics of my work.....

#2

Seasoned Member

Join Date: Jul 2010

Location: Mass.

Posts: 320

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Check and make sure the clutch plate is still centered. What year and where is the slave cylinder? Make sure the throw out bearing and arm are in the right place.

#4

Junior Member

Thread Starter

Join Date: Feb 2012

Location: Englewood!

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1994

Model: Cherokee

Engine: 4.0

Slave cylinder is almost brand new: Bought it in 2009. Same with throwout bearing. I made sure the throw out bearing is back far enough and not overly lubricated.

Have y'all ever heard of a clutch plate becoming misaligned during an uninstall without removing the pressure plate or clutch disk? I threw a socket in there and to the eye it looks centered.

Alnielsen,

Apparently in the Denver metro area it is illegal to have a clutch allignment tool because no one sells them (j/k). I am looking for one, but have had no luck yet. : (

Have y'all ever heard of a clutch plate becoming misaligned during an uninstall without removing the pressure plate or clutch disk? I threw a socket in there and to the eye it looks centered.

Alnielsen,

Apparently in the Denver metro area it is illegal to have a clutch allignment tool because no one sells them (j/k). I am looking for one, but have had no luck yet. : (

#5

Junior Member

Thread Starter

Join Date: Feb 2012

Location: Englewood!

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1994

Model: Cherokee

Engine: 4.0

UPDATE:

I took off the cross member for better leverage and exaust is completely out of the way. Still no luck after another 3 hours today. That makes about 30 hours of attempting to get the trans back into the engine.

I took off the cross member for better leverage and exaust is completely out of the way. Still no luck after another 3 hours today. That makes about 30 hours of attempting to get the trans back into the engine.

#6

Junior Member

Thread Starter

Join Date: Feb 2012

Location: Englewood!

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1994

Model: Cherokee

Engine: 4.0

One other question....I am about to go buy the 1 ton $140 trans jack from Harbor Freight. Does anyone know if it works well? I did read the other posts on here for tricks on getting the trans and engine to marry, but no joy on any strategy.

Trending Topics

#8

Senior Member

Join Date: Jul 2011

Location: Red Lion, PA

Posts: 675

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1991

Model: Cherokee(XJ)

Engine: 4.0

one thing ive found that really helps is to put the transmission in gear then turn the output shaft while your trying to slide the tranny in. That way if your having a problem with splines lining up they will usually slip together.

#9

Seasoned Member

Join Date: Jan 2012

Location: Smithfield, VA

Posts: 401

Likes: 0

Received 1 Like

on

1 Post

Year: 1997

Model: Cherokee

Engine: 4.0

A broom handle or a wooden dowel thats very close to the size of the shaft will do just fine. As suggested, put tranny in gear so you can turn the shaft to align the splines. If it came out it has to go back. Obvisouly something has gotten out of alignment for some reason. Maybe just pull the clutch and see exaclty whats in your way.

#10

Senior Member

Join Date: Jan 2012

Location: DuPage County, IL

Posts: 701

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1994

Model: Cherokee

Engine: 4.0L I6 HO

I've just used a regular cheap floor jack when I had to remove/install a trans.

#11

CF Veteran

Join Date: Nov 2011

Location: Edmonton

Posts: 2,322

Likes: 0

Received 1 Like

on

1 Post

Year: 1990

Model: Cherokee

Engine: 4.0

in the second pic, your angles are way off. i had to do this myself recently as well. i got it close and then eyeballed my gap all the way around making sure it was even. i never had to put it in gear...once it gets close it will turn itself into alignment. thats why its beveled on the end. the only way the clutch would come out of alignment is if you hit it really hard somehow, or youve got loose bolts to begin with. i found it worked better to "twist" the tranny on axis with the motor, with the motor tilted pretty far down. (i know its a lot of stress on the mounts but it worked for me lol) hope this helps, i know what youre going through. the first time i did it i had my brother helping me, the second time was to do that stupid internal slave, and i had no help.

go to a tranny shop, tell them what you have and they might lend you an old cut off input shaft for alignment. nothing less is acceptable here, you already know this because of your difficulty.

go to a tranny shop, tell them what you have and they might lend you an old cut off input shaft for alignment. nothing less is acceptable here, you already know this because of your difficulty.

Last edited by hankthetank; 02-14-2012 at 08:32 AM.

#12

Seasoned Member

Join Date: Jul 2010

Location: Mass.

Posts: 320

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

in the second pic, your angles are way off. i had to do this myself recently as well. i got it close and then eyeballed my gap all the way around making sure it was even. i never had to put it in gear...once it gets close it will turn itself into alignment. thats why its beveled on the end. the only way the clutch would come out of alignment is if you hit it really hard somehow, or youve got loose bolts to begin with. i found it worked better to "twist" the tranny on axis with the motor, with the motor tilted pretty far down. (i know its a lot of stress on the mounts but it worked for me lol) hope this helps, i know what youre going through. the first time i did it i had my brother helping me, the second time was to do that stupid internal slave, and i had no help.

go to a tranny shop, tell them what you have and they might lend you an old cut off input shaft for alignment. nothing less is acceptable here, you already know this because of your difficulty.

go to a tranny shop, tell them what you have and they might lend you an old cut off input shaft for alignment. nothing less is acceptable here, you already know this because of your difficulty.

#13

Junior Member

Thread Starter

Join Date: Feb 2012

Location: Englewood!

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1994

Model: Cherokee

Engine: 4.0

Update: I took VD off to spend time with my Wife. Back at it today, I am taking y'alls advice and removed the clutch and Fly Wheel. If you're in the Denver area, check out Clutch Doctor. They are selling me a clutch for145 and machining the flywheel for 25.

9440: I agree that replacing the clutch is my best bet.

Jeep19xj91: I do have it in first or 3rd. I also have it in 4WD so I can turn the front driveshafe connect with a pry bar

jpeade: I used a socket and it looked pretty centered. I really didn't want to pull the clutch but you have to do what you have to do.

Alnielsen: I am not as brave as you. I will probably get there. A professional isn't graded by what they can do, but what they can do without. I hope to be at your level one day.

Hank The Tank: I twisted it about 40 degrees and no joy. I also agree that the angle was off. I losened the straps and used my arms to twist it in every direction. I also found the jack I was using was dragging instead of rolling so most of my energy was spent on dragging it forward.

Leecarr: I agree that it just needs to be muscled. Monday night I spent three hours using force instead of the jack to maneuver it in all directions. One reason this may not work is because I have my front on 6 ton jacks and high enough that I can sit cross legged where the trans should be.

9440: I agree that replacing the clutch is my best bet.

Jeep19xj91: I do have it in first or 3rd. I also have it in 4WD so I can turn the front driveshafe connect with a pry bar

jpeade: I used a socket and it looked pretty centered. I really didn't want to pull the clutch but you have to do what you have to do.

Alnielsen: I am not as brave as you. I will probably get there. A professional isn't graded by what they can do, but what they can do without. I hope to be at your level one day.

Hank The Tank: I twisted it about 40 degrees and no joy. I also agree that the angle was off. I losened the straps and used my arms to twist it in every direction. I also found the jack I was using was dragging instead of rolling so most of my energy was spent on dragging it forward.

Leecarr: I agree that it just needs to be muscled. Monday night I spent three hours using force instead of the jack to maneuver it in all directions. One reason this may not work is because I have my front on 6 ton jacks and high enough that I can sit cross legged where the trans should be.

#14

Junior Member

Thread Starter

Join Date: Feb 2012

Location: Englewood!

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1994

Model: Cherokee

Engine: 4.0

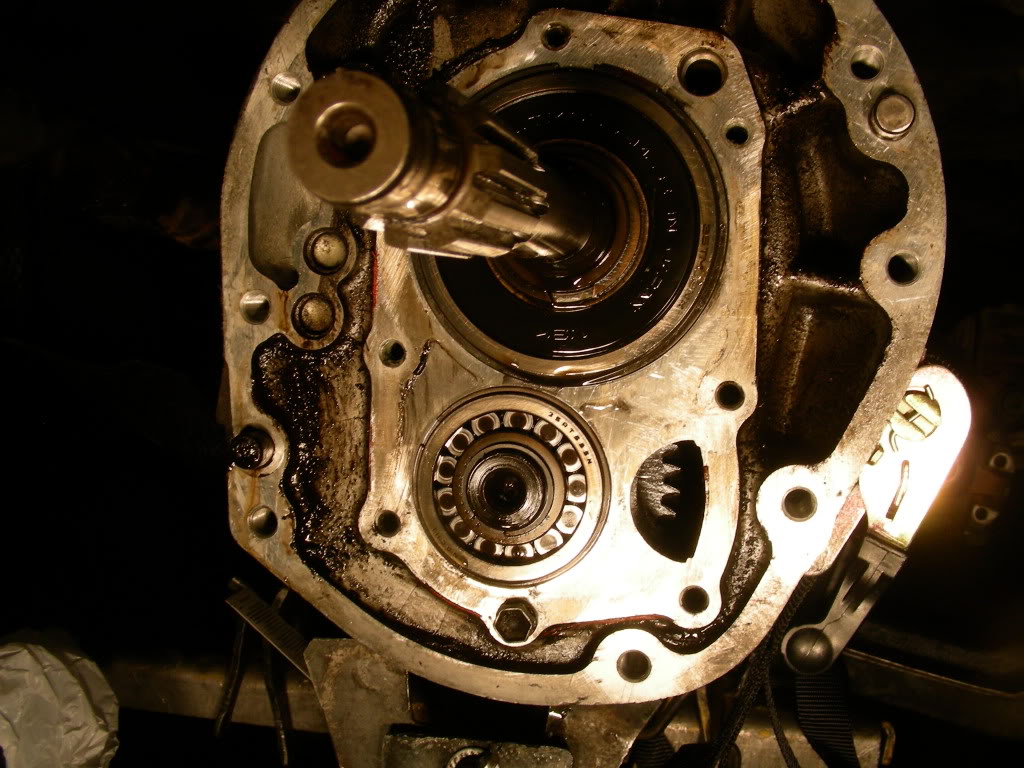

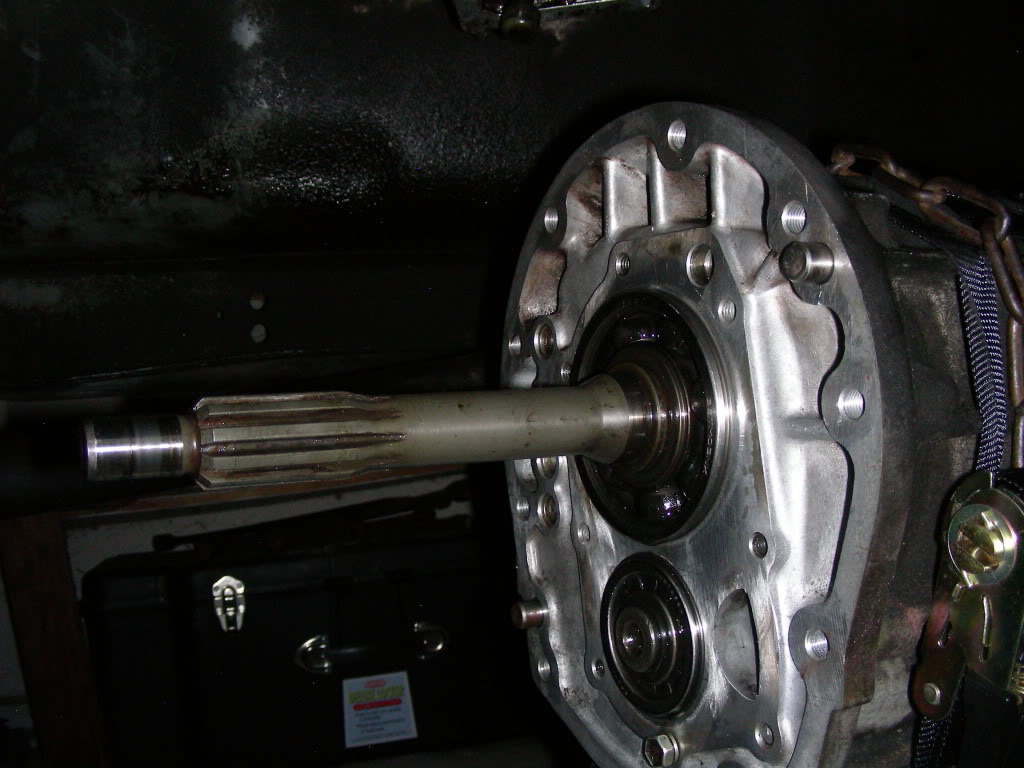

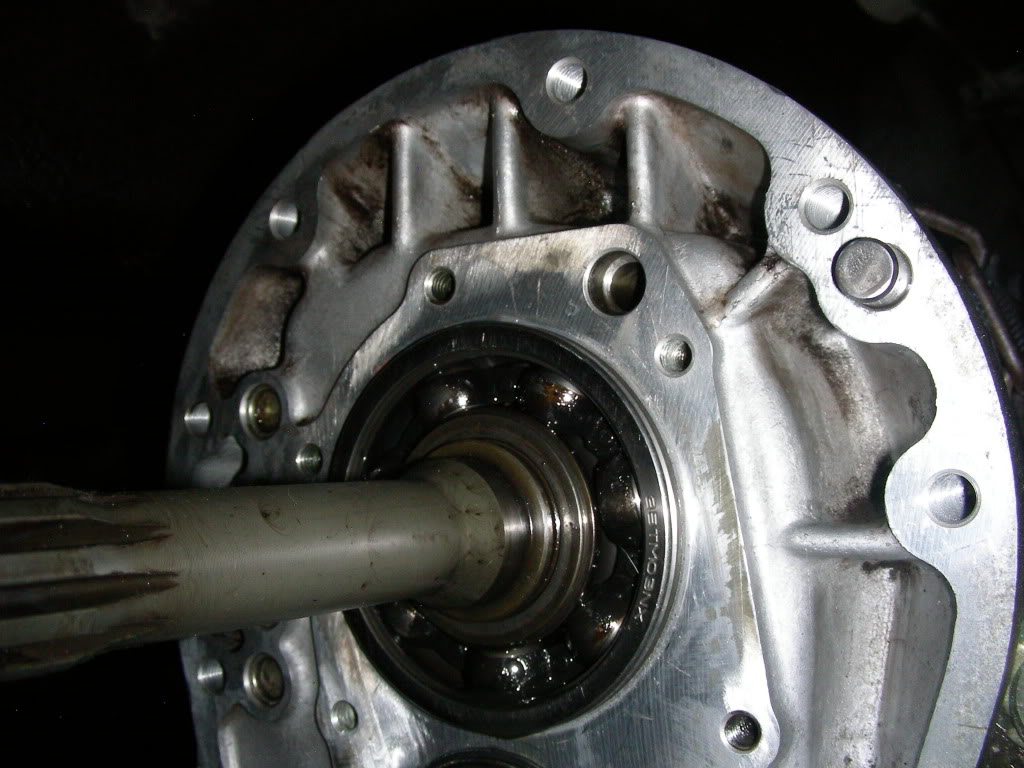

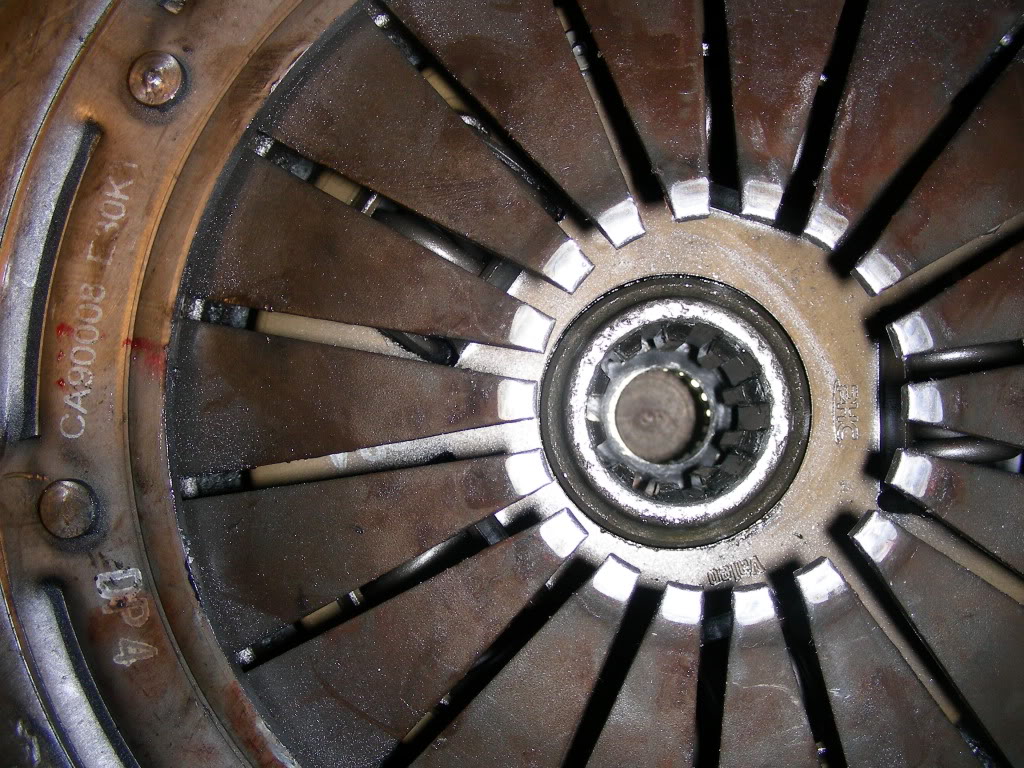

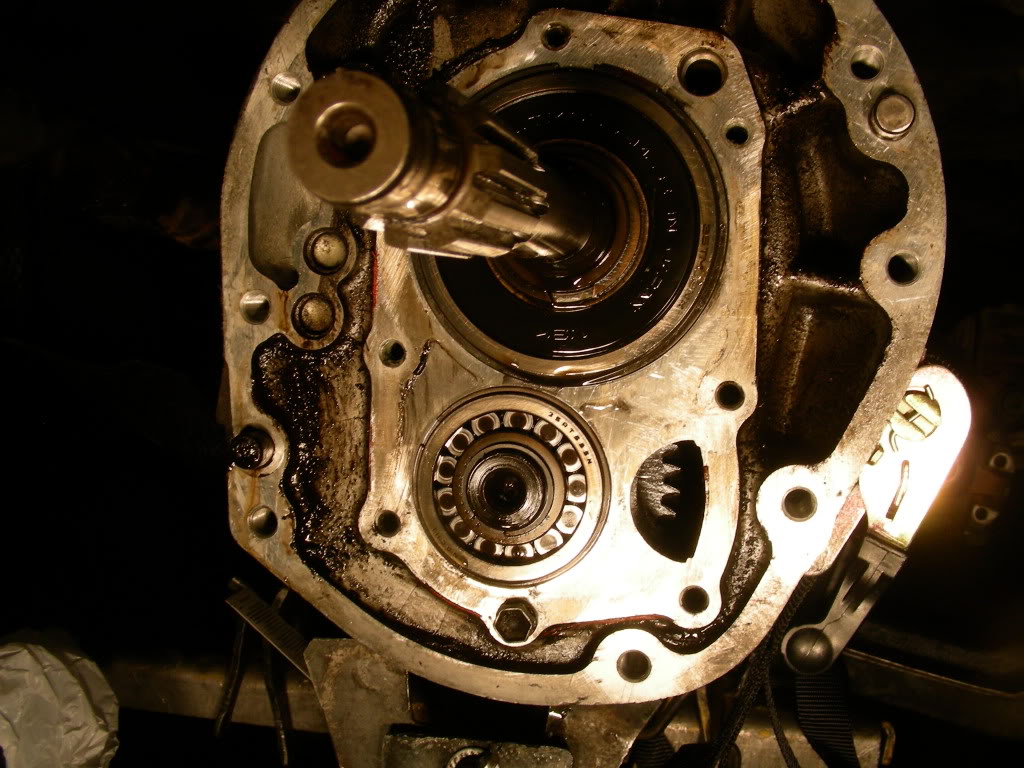

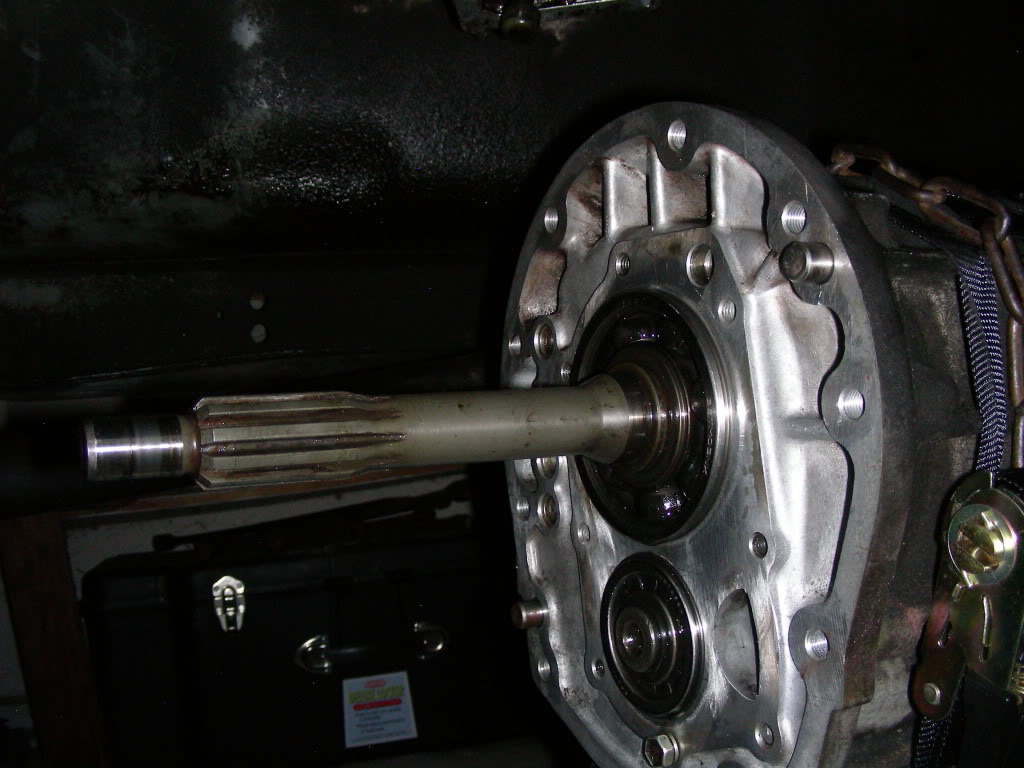

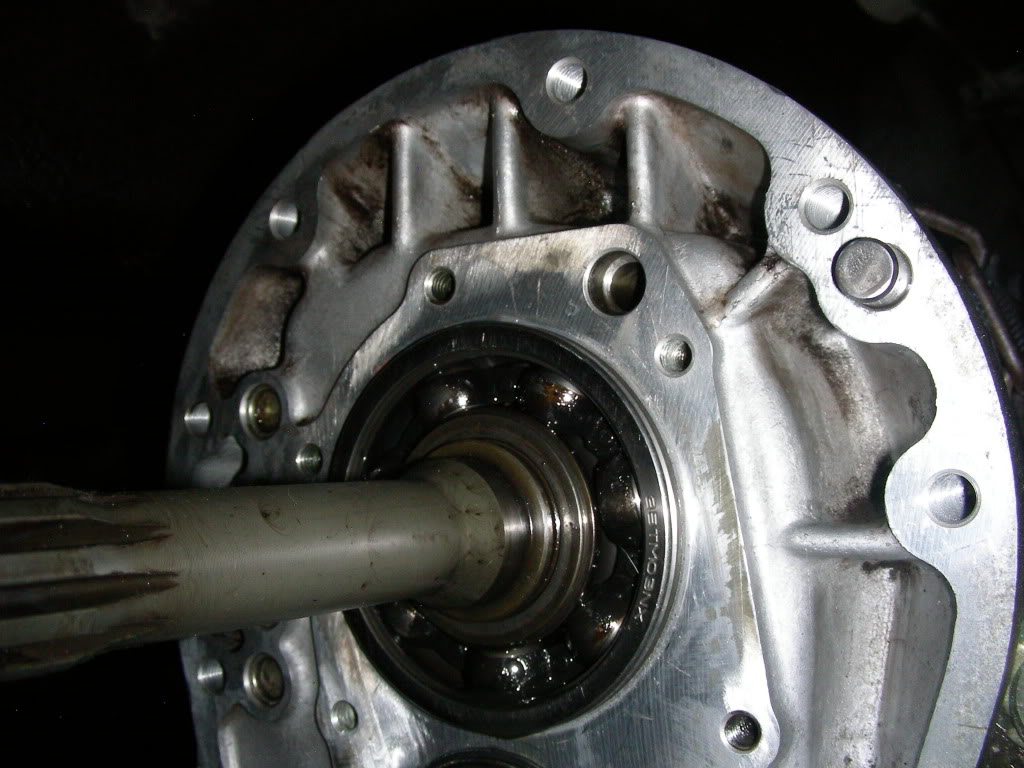

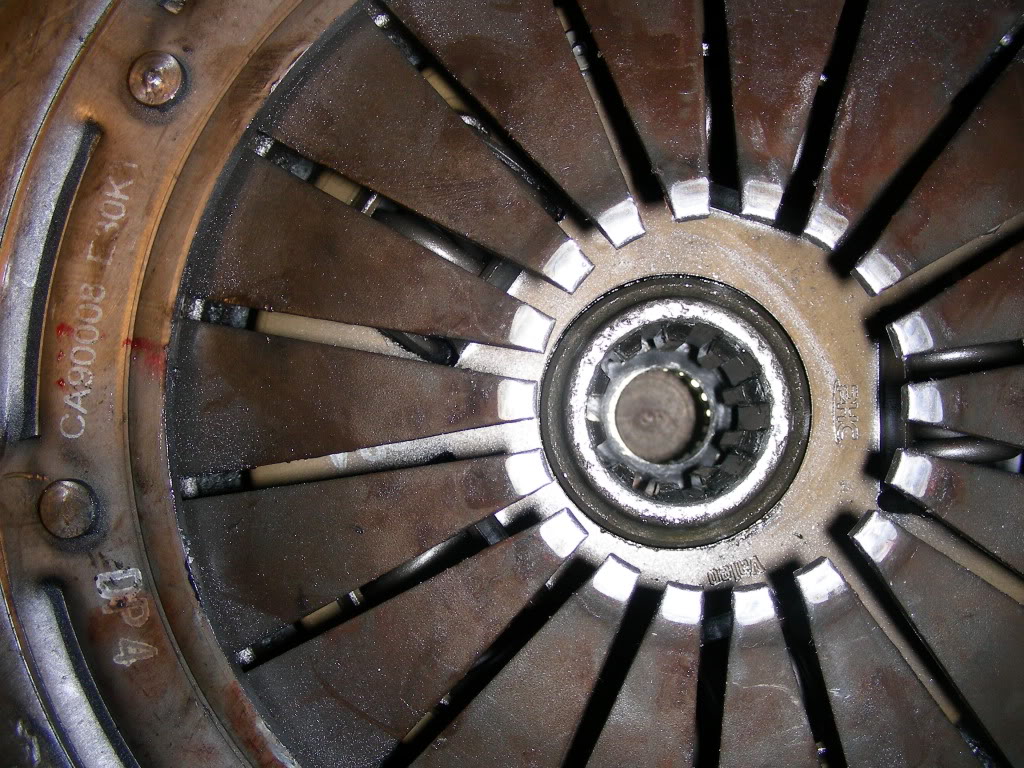

Here are more pictures from taking out the clutch:

When I dropped it:

Cleaned before the input shaft crown was installed:

Poor puppy had a hard day in the house waiting:

Clutch Pressure Plate

Pressure plate, clutch, and fly wheel out:

Rear of engine....I will be changing the rear main seal while this is out:

I feel like a piece of crap that my starter looks like this. I try to take care of the environment so I am motivated to make my jeep run better:

Flywheel cleaned after degreaser:

Poor person's degreaser:

Bell Housing degreased:

MOPAR RTV ($20 per bottle) added to input shaft crown:

Thanks for looking! Flywheel is being turned tomorrow: Trans will be in this weekend with the help of this community! Thank you all so very much! Hope you enjoy the pictures!

When I dropped it:

Cleaned before the input shaft crown was installed:

Poor puppy had a hard day in the house waiting:

Clutch Pressure Plate

Pressure plate, clutch, and fly wheel out:

Rear of engine....I will be changing the rear main seal while this is out:

I feel like a piece of crap that my starter looks like this. I try to take care of the environment so I am motivated to make my jeep run better:

Flywheel cleaned after degreaser:

Poor person's degreaser:

Bell Housing degreased:

MOPAR RTV ($20 per bottle) added to input shaft crown:

Thanks for looking! Flywheel is being turned tomorrow: Trans will be in this weekend with the help of this community! Thank you all so very much! Hope you enjoy the pictures!

#15

Senior Member

Join Date: Jul 2011

Location: Red Lion, PA

Posts: 675

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1991

Model: Cherokee(XJ)

Engine: 4.0

good choice on replacing the clutch, not one part of it really looks good. Always best to go new when doing a job like that