Gas gauge problems

#16

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

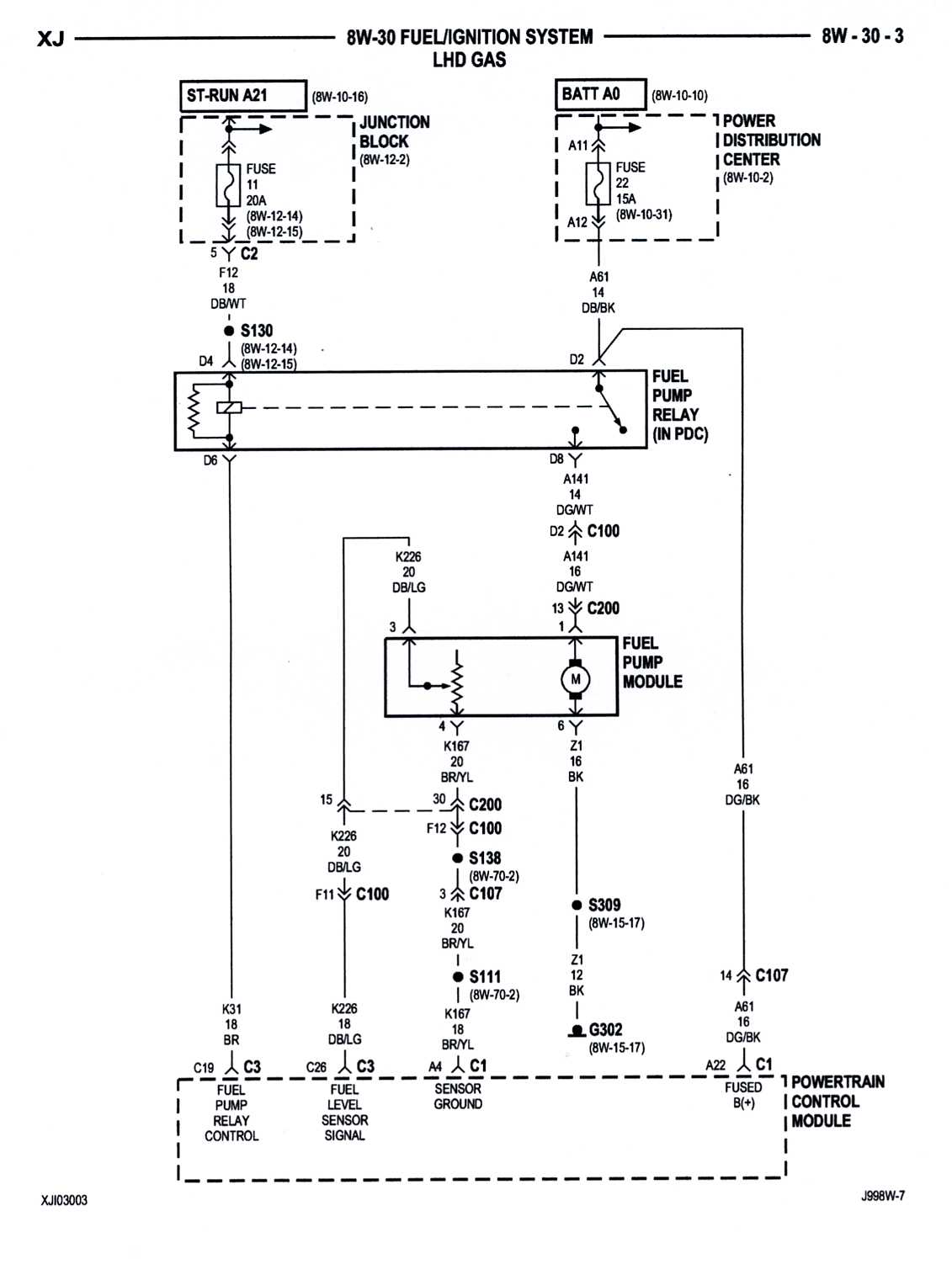

Just some FYI: The Power Train Control Module (PCM) receives signals from the various instrument sensors and sends the associated data to the instruments through the Chrysler Crash Detection (CDCD) Data Bus.

There are two CCD Data Bus wires that go from the PCM to the instrument cluster that accomplishes the data transfer from the PCM to the instruments in the instrument cluster. For the Voltmeter, Oil Pressure, Coolant Temperature, and Fuel Quantity, there are no seperate wires going to the instrument cluster.

There is a test that can be performed from the driver's seat that will show if an instrument in the cluster is faulty. Do this test before changing sensors or pulling the instrument cluster out.

Instrument Cluster Actuator Test

(1) Begin the test with the ignition switch in the Off position.

(2) Depress the trip odometer reset button.

(3) While holding the trip odometer reset button depressed, turn the ignition switch to the On position, but do not start the engine.

(4) Release the trip odometer reset button.

(5) The gauges should cycle through their ranges, stopping at intermediate readings, going up and going down, at two second intervals. The indicator lamps should cycle on and off.

(6) The instrument cluster will automatically exit the self-diagnostic mode and return to normal operation at the completion of the test, if the ignition switch is turned to the Off position during the test, or if a vehicle speed message indicating that the vehicle is moving is received from the PCM on the CCD data bus during the test.

There are two CCD Data Bus wires that go from the PCM to the instrument cluster that accomplishes the data transfer from the PCM to the instruments in the instrument cluster. For the Voltmeter, Oil Pressure, Coolant Temperature, and Fuel Quantity, there are no seperate wires going to the instrument cluster.

There is a test that can be performed from the driver's seat that will show if an instrument in the cluster is faulty. Do this test before changing sensors or pulling the instrument cluster out.

Instrument Cluster Actuator Test

(1) Begin the test with the ignition switch in the Off position.

(2) Depress the trip odometer reset button.

(3) While holding the trip odometer reset button depressed, turn the ignition switch to the On position, but do not start the engine.

(4) Release the trip odometer reset button.

(5) The gauges should cycle through their ranges, stopping at intermediate readings, going up and going down, at two second intervals. The indicator lamps should cycle on and off.

(6) The instrument cluster will automatically exit the self-diagnostic mode and return to normal operation at the completion of the test, if the ignition switch is turned to the Off position during the test, or if a vehicle speed message indicating that the vehicle is moving is received from the PCM on the CCD data bus during the test.

#17

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

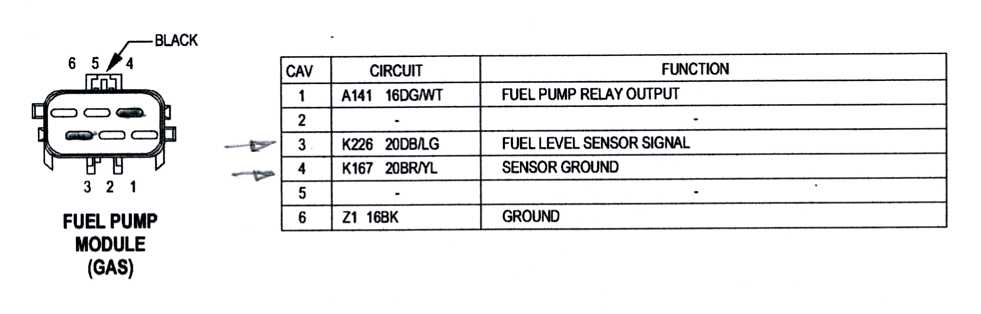

The fuel level indication system does not have a seperate ground. There are two wires in the fuel pump module connector that carries the fuel level data to the PCM, neither of which is a ground.

#18

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

My girlfriend has a 98 xj with the 4.0 with aw4. 158k miles on the clock. From the beginning, the gas gauge has not been displaying properly. When the tank is full, it would function normally, until it get to between 1/4 to 3/8 full, then it would drop down beyond E and get the light to turn on. Sometimes she would have to turn off and turn it back on and it would function normally.

Her dad bought new fuel pump and sending unit brand new and installed it, and we both saw the old sending unit, it was really bad. We thought it solved the problem.

The gauge still has not improved. It still display that the tank is empty but we know there's still some gas left. I m wondering if there's problems with the gauge cluster or a connection somewhere?

Is there a computer that controls the gauge cluster somewhere? I want to be able to check the ground connections on that module. U know how Cruiser54 always say RCBRC.

I noticed that there's a computer module mounted right behind the emergency brake lever on the center console. Do that have anything to do with the gauge cluster?

Any input would be greatly appreciated.

Her dad bought new fuel pump and sending unit brand new and installed it, and we both saw the old sending unit, it was really bad. We thought it solved the problem.

The gauge still has not improved. It still display that the tank is empty but we know there's still some gas left. I m wondering if there's problems with the gauge cluster or a connection somewhere?

Is there a computer that controls the gauge cluster somewhere? I want to be able to check the ground connections on that module. U know how Cruiser54 always say RCBRC.

I noticed that there's a computer module mounted right behind the emergency brake lever on the center console. Do that have anything to do with the gauge cluster?

Any input would be greatly appreciated.

I take it that it was the module assembly and not just the fuel pump and a sending unit...correct?

#19

CF Veteran

Thread Starter

Join Date: Jan 2013

Location: west chester, pa

Posts: 19,216

Likes: 0

Received 39 Likes

on

35 Posts

Year: 1999

Engine: 4.0

Yes I performed the self diagnostic test three separate occasions prior to the removal of the cluster. Everything indicated that each gauge worked properly like it should be.

#20

CF Veteran

Thread Starter

Join Date: Jan 2013

Location: west chester, pa

Posts: 19,216

Likes: 0

Received 39 Likes

on

35 Posts

Year: 1999

Engine: 4.0

Her dad installed brand new Bosch fuel pump assembly with new filter and level sensor from napa. So basically everything that goes inside the tank is replaced.

#21

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

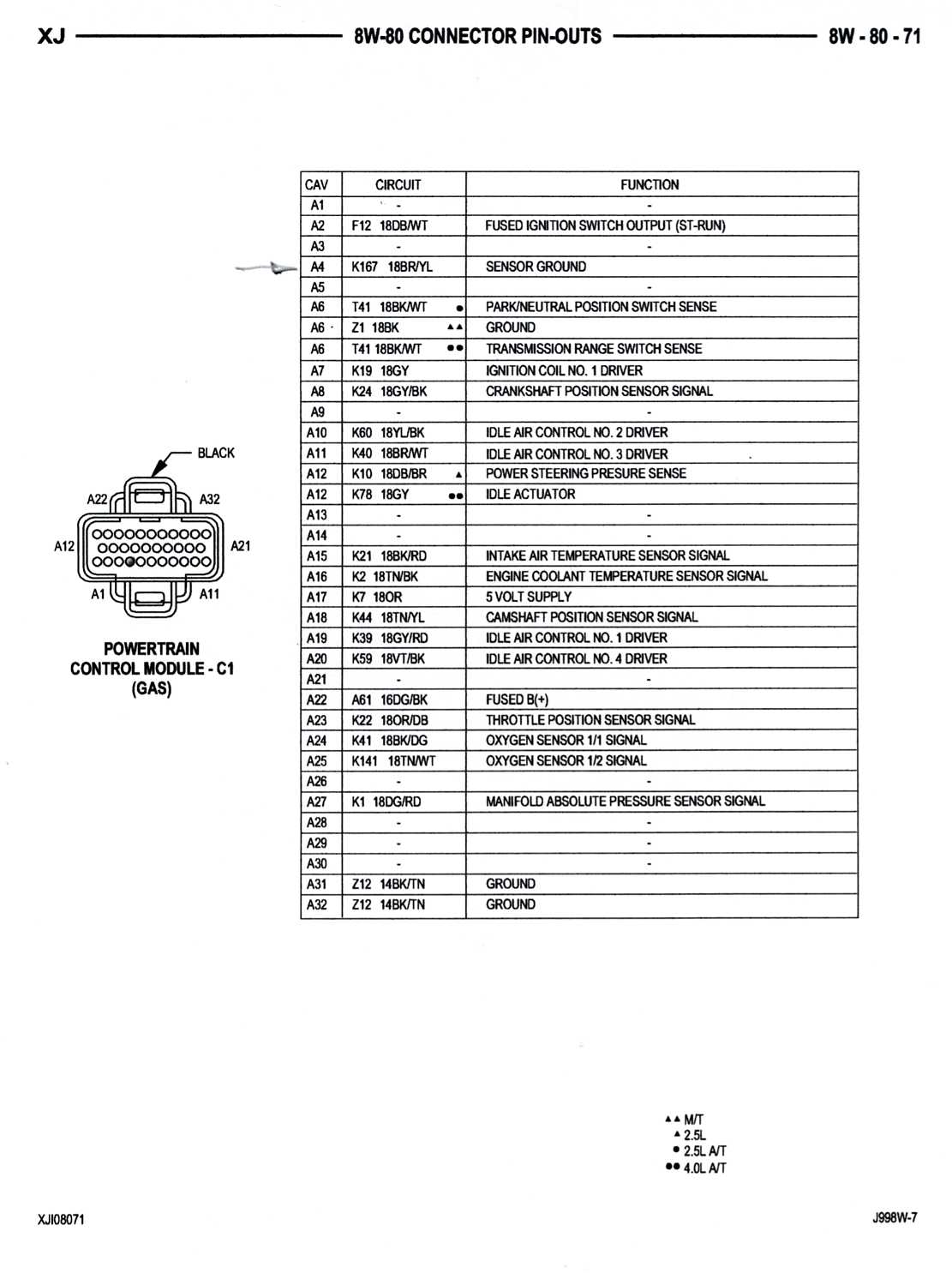

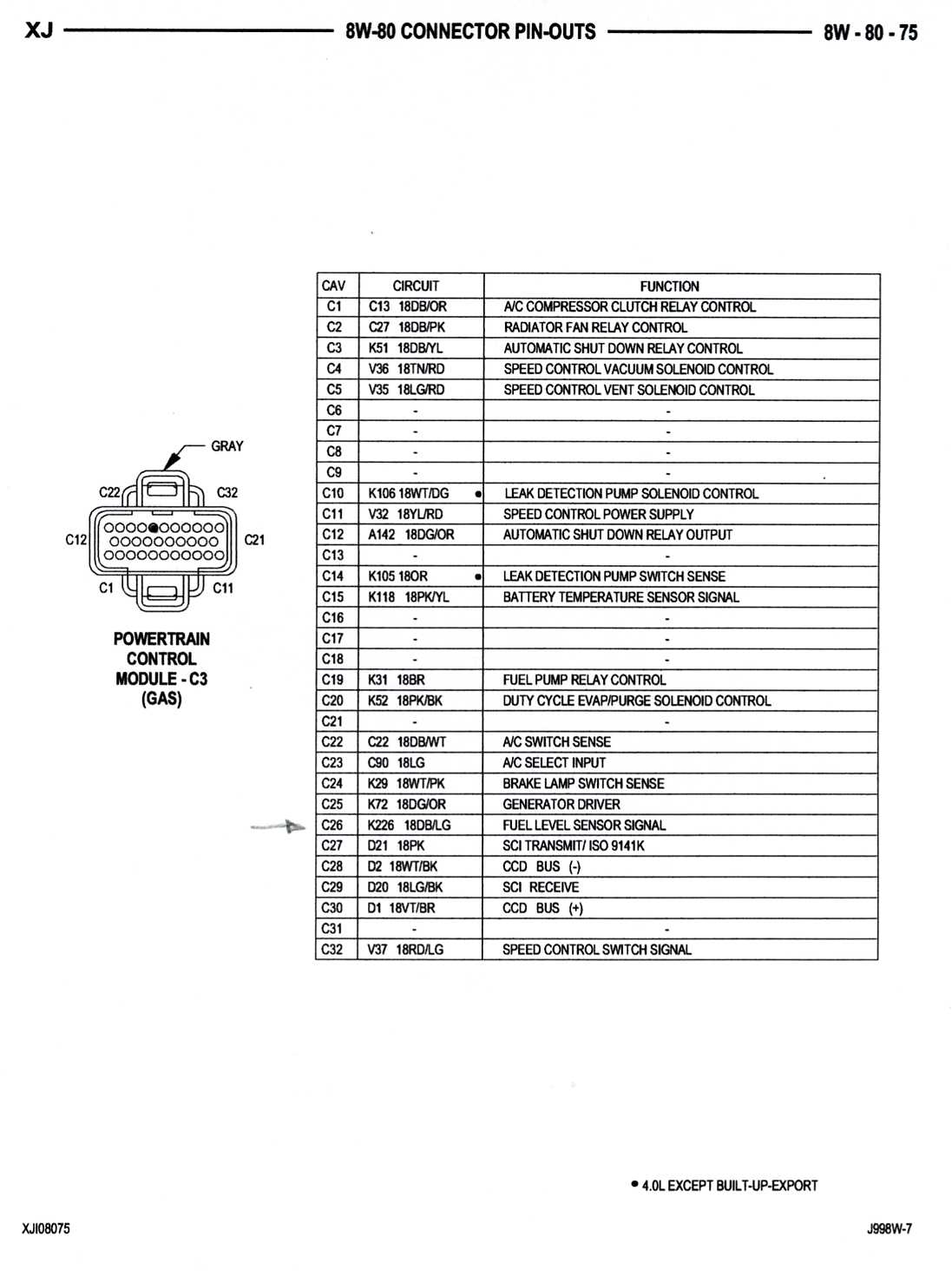

If you feel venturesome and have a digital Ohmmeter I will post the connector pinouts for the PCM and the fuel pump module connector so you can check the wires for high resistance.

Note that the fuel level sender variable resistor generates 20 ohms +/- 5% with the float full up and 270 ohms +/- 1.2 % with the float full down.

#22

CF Veteran

Thread Starter

Join Date: Jan 2013

Location: west chester, pa

Posts: 19,216

Likes: 0

Received 39 Likes

on

35 Posts

Year: 1999

Engine: 4.0

It would appear then that the problem exists between the fuel pump module connector (body harness side of the connector) to the PCM. The circuit is running accross high resistance somewhere. Unfortunately, the fuel level sensor signal and sensor return wires go through three connectors and two spices between the pump connector and the PCM.

If you feel venturesome and have a digital Ohmmeter I will post the connector pinouts for the PCM and the fuel pump module connector so you can check the wires for high resistance.

Note that the fuel level sender variable resistor generates 20 ohms +/- 5% with the float full up and 270 ohms +/- 1.2 % with the float full down.

#23

CF Veteran

Join Date: Dec 2012

Location: York, PA

Posts: 4,169

Likes: 0

Received 6 Likes

on

6 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

CCKen, thanks for the great information! I haven't done the cluster test yet for my problem, but I certainly will when I have the chance. Interested to see what you find, XJwonders!

#24

Member

Join Date: Sep 2012

Location: HBG, PA

Posts: 230

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0L

I think that the light will come on when there is 3 gallons or so left. Is that what you mean? Since the replacement, has the other problem gone away? It was very common for 97 and above sending units to fail...my '98 is doing the exact same thing. After a half tank, it jumps to E and back all the time. I never really know how much gas I have, lol

Someone find a fix for this asap!!!

#25

Junior Member

Join Date: Jun 2013

Location: NE Missouri

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

Our 01 Sport gas gauge has a different problem; when you fill it up it only goes to 3/4 full and when it's down to a quarter it still has about 8 gallons left .

.

.

.

#26

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Your meter should have a feature to read resistance (Ohms). The meter may have an Omega symble on it with various ranges. If you see it, select 20K (20,000 Ohms) and touch both leads together, then release them. You'll see the meter react. When they are touched together that would be full continuity, when they are apart, that would be full resistance, or infinity.

You'll need a length of 18 gauge wire that will reach from the fuel pump connector to the PCM in the engine bay. This will be the long arm of one of your meter leads. Make sure your meter has alligator clips for the leads (at least one).

Later.

#27

Yes please post findings! I think this is fairly common and there isn't much documented other than "replace everything". Is it possible to run a completely different fuel guage? I know it won't be in the dash, but it may be an easier solution. Kinda mount one on the dash or something?

#28

98 jeep cherokee sport - AT, 4.0 Liter, rebuilt engine ....

I have problem where fuel guage reads full when full & is empty when guage reads 1/2 full...

This was after new Airtech fuel pump with level assy was installed in an attempt to remedy low fuel pressure issue... also have intermittent guage /cluster failure, airbag light comes on and off, door locks work then don't work... & engine will not stay running when started...

All these issues occur intermitently except for fuel guage reading incorrect... everything fine for a few weeks then no start/run, no door locks, windows, guages go to zero.... so i give up.... come back later turn the key & everything is fine for a few days or weeks then... some magic occurs & it just turns off while dirving...

when it does not want to idle - if I hold down the accelerator a little bit- it will stay running & allow me to drive, but when the accelerator is fully released the engine dies...

I have taken it into the shop - no codes - and no problems - some majic happens & everything is ok... the mechanic has kept it for over 3 weeks on 2 different occasions and used it as a daily driver & for shop erands with no repeat problems ... this has happened twice now & the shop guys have no ideas...

could there be sensor issues where an intermittent break would cause a shutdown... i.e. bad connection or intermittent break in sensor wire/connection to temp sensor, crank position sensor, etc. would cause this... or would bad connection/ground to door locks, windows circuits be involved???? this is too bizarre... & a long standing issue...

I have problem where fuel guage reads full when full & is empty when guage reads 1/2 full...

This was after new Airtech fuel pump with level assy was installed in an attempt to remedy low fuel pressure issue... also have intermittent guage /cluster failure, airbag light comes on and off, door locks work then don't work... & engine will not stay running when started...

All these issues occur intermitently except for fuel guage reading incorrect... everything fine for a few weeks then no start/run, no door locks, windows, guages go to zero.... so i give up.... come back later turn the key & everything is fine for a few days or weeks then... some magic occurs & it just turns off while dirving...

when it does not want to idle - if I hold down the accelerator a little bit- it will stay running & allow me to drive, but when the accelerator is fully released the engine dies...

I have taken it into the shop - no codes - and no problems - some majic happens & everything is ok... the mechanic has kept it for over 3 weeks on 2 different occasions and used it as a daily driver & for shop erands with no repeat problems ... this has happened twice now & the shop guys have no ideas...

could there be sensor issues where an intermittent break would cause a shutdown... i.e. bad connection or intermittent break in sensor wire/connection to temp sensor, crank position sensor, etc. would cause this... or would bad connection/ground to door locks, windows circuits be involved???? this is too bizarre... & a long standing issue...

#29

98 jeep cherokee sport - AT, 4.0 Liter, rebuilt engine ....

I have problem where fuel guage reads full when full & is empty when guage reads 1/2 full...

This was after new Airtech fuel pump with level assy was installed in an attempt to remedy low fuel pressure issue... also have intermittent guage /cluster failure, airbag light comes on and off, door locks work then don't work... & engine will not stay running when started...

All these issues occur intermitently except for fuel guage reading incorrect... everything fine for a few weeks then no start/run, no door locks, windows, guages go to zero.... so i give up.... come back later turn the key & everything is fine for a few days or weeks then... some magic occurs & it just turns off while dirving...

when it does not want to idle - if I hold down the accelerator a little bit- it will stay running & allow me to drive, but when the accelerator is fully released the engine dies...

I have taken it into the shop - no codes - and no problems - some majic happens & everything is ok... the mechanic has kept it for over 3 weeks on 2 different occasions and used it as a daily driver & for shop erands with no repeat problems ... this has happened twice now & the shop guys have no ideas...

could there be sensor issues where an intermittent break would cause a shutdown... i.e. bad connection or intermittent break in sensor wire/connection to temp sensor, crank position sensor, etc. would cause this... or would bad connection/ground to door locks, windows circuits be involved???? this is too bizarre... & a long standing issue...

I have problem where fuel guage reads full when full & is empty when guage reads 1/2 full...

This was after new Airtech fuel pump with level assy was installed in an attempt to remedy low fuel pressure issue... also have intermittent guage /cluster failure, airbag light comes on and off, door locks work then don't work... & engine will not stay running when started...

All these issues occur intermitently except for fuel guage reading incorrect... everything fine for a few weeks then no start/run, no door locks, windows, guages go to zero.... so i give up.... come back later turn the key & everything is fine for a few days or weeks then... some magic occurs & it just turns off while dirving...

when it does not want to idle - if I hold down the accelerator a little bit- it will stay running & allow me to drive, but when the accelerator is fully released the engine dies...

I have taken it into the shop - no codes - and no problems - some majic happens & everything is ok... the mechanic has kept it for over 3 weeks on 2 different occasions and used it as a daily driver & for shop erands with no repeat problems ... this has happened twice now & the shop guys have no ideas...

could there be sensor issues where an intermittent break would cause a shutdown... i.e. bad connection or intermittent break in sensor wire/connection to temp sensor, crank position sensor, etc. would cause this... or would bad connection/ground to door locks, windows circuits be involved???? this is too bizarre... & a long standing issue...

Btw, the harsh idle, stalling etc, I had a similar issues. Codes would throw than clear. Ultimately ended up being two things. O2 sensor and I cleaned the throttle body. Problem hasn't come back.

#30

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

I'll have to scan the diagrams, etc., this evening and post them up.

Your meter should have a feature to read resistance (Ohms). The meter may have an Omega symble on it with various ranges. If you see it, select 20K (20,000 Ohms) and touch both leads together, then release them. You'll see the meter react. When they are touched together that would be full continuity, when they are apart, that would be full resistance, or infinity.

You'll need a length of 18 gauge wire that will reach from the fuel pump connector to the PCM in the engine bay. This will be the long arm of one of your meter leads. Make sure your meter has alligator clips for the leads (at least one).

Later.

Your meter should have a feature to read resistance (Ohms). The meter may have an Omega symble on it with various ranges. If you see it, select 20K (20,000 Ohms) and touch both leads together, then release them. You'll see the meter react. When they are touched together that would be full continuity, when they are apart, that would be full resistance, or infinity.

You'll need a length of 18 gauge wire that will reach from the fuel pump connector to the PCM in the engine bay. This will be the long arm of one of your meter leads. Make sure your meter has alligator clips for the leads (at least one).

Later.

The Chrysler diagnostics steps for various problems calls for less than .5 Ohms in the wiring being checked so I think .5 Ohms is a good number NOT to exceed when checking the resistance of the fuel level wiring.

If you're not familiar with the Power Train Module (PCM) connectors, connector C3 is the Gray connector nearest the firewall, C2 is the middle one, and C1 is closest to the radiator. To disconnect the PCM connectors depress the middle lock tab and pull the connector straight out. The two tabs on either side of the middle lock tab release the cover over the end of the connector.

Before starting any resistance readings with your Ohmmeter, disconnect and isolate the battery negative (-) connector.

Here's the images you'll be referring to. In the wiring diagram you can see the fuel level variable resistor in the fuel pump module. I've darkened the pin cavities in the connector that you will be using. The connector pinouts are the body harness end of the connector.

.Disconnect the fuel pump module connector and the PCM connectors C1 and C3. Examine the pins and pin cavities of these connectors for corrosion. Corrosion may appear as black or dark gray.

Read from the FP connector, pin cavity 3 to PCM connector C3, pin cavity C26 using the jumper I mentioned. Have a helper hold the jumper on the PCM pin cavity C3/C26 while you connect to the jumper with the (-) probe of the meter and (+) probe of the meter to FP pin cavity 3. Record the resistance you see on the Ohmmeter.

Repeat the process, going from PCM C1/A4 to FP 4. Record the resistance reading.

Any reading over .5 Ohms should be suspect as having too high of a resistance.

Tell us what you find.

Good luck.

Edit:

Note that the fuel level sender variable resistor generates 20 ohms +/- 5% with the float full up and 270 ohms +/- 1.2 % with the float full down.

If you want, you can reconnect the FP connector and read between PCM C3/26 and C1/A4 to see what resistance you get from the fuel level variable resistor in the FP module. Depending upon how much fuel you actully have in your tank, the resistance should fall within the values above.

Last edited by CCKen; 08-16-2013 at 09:05 AM.