Can't get UCA bolts to move.

#1

Member

Thread Starter

How did you guys get that hard to reach pass side UCA bolt out up in the frame? After contorting myself to breack the nut loose (no room for impact wrench or even socket....all box wrench). Now I got the nut off, and can't get the bolt to slide out. Can't even get in there to get an air hammer on it.

btw - I am trying to remove the upper control arm to replace the bushings on a 99 XJ Sport

edit- Ok, now I am . I can't get the axle end bolt out either. It won't budge. What is the deal? I am not going to even attemp the drivers side if the pass side is this hard.

. I can't get the axle end bolt out either. It won't budge. What is the deal? I am not going to even attemp the drivers side if the pass side is this hard.

btw - I am trying to remove the upper control arm to replace the bushings on a 99 XJ Sport

edit- Ok, now I am

. I can't get the axle end bolt out either. It won't budge. What is the deal? I am not going to even attemp the drivers side if the pass side is this hard.

. I can't get the axle end bolt out either. It won't budge. What is the deal? I am not going to even attemp the drivers side if the pass side is this hard.

#3

CF Veteran

From this bracket? Spray PB on it and get it in there good. You should be able to get a socket on it thru the hole in the frame and break it loose.

#4

Member

Thread Starter

I got the nut off, but I can't get the bolt out. And I can't spin the bolt.....there is a flat oblong "flange" tack welded to it so that it won't spin. I am guessing this is so that you can tighten the nut without having to get into the frame.

Here is the axle end. This bolt won't budge either.

Here is the axle end. This bolt won't budge either.

Last edited by Mudshack; 04-10-2010 at 05:45 PM.

#5

CF Veteran

I got mine out by tapping them out with a hammer. But in the bolt is rusted right inside the bushing and won't budge. That was the problem I had with my rear springs I ended up cutting the bolt on both sides of the bushing with a sawzall on the inside of the bracket. It's sucks but sometimes thats the last resort.

#6

Member

Thread Starter

I have avoided buying a sawzall for so long. And I figured this would be a simple afternoon job (with a ball joint press from O'Reillys). This is so frustrating. Ever time I touch this XJ, the simple jobs turn into EPIC WRENCH-A-THONS!

#7

CF Veteran

AHHH one thing!! Do you have all the pressure off the bolts? Idk how you have it jacked up. But May have to support the body on jack stands and use a floor jack under the axle to get the pressure off because those don't even look as bad as mine were.

Trending Topics

#8

Member

Thread Starter

I just was going to ask the same question. I have the body up on stands. And I have tried the jack under the axle with it raised high....and with it lowered all the way down.

Now...update. I pounded the crud out of the axel side bolt. I got it to moved to the point that I can no longer hit it (the tip is inside the control arm). I can't get it to pull through anymore by prying, and worse yet. It looks like it is not lined up to be pushed back through. I am pounding the snot out of it to try and get it back through but it is binding on the the inside of the control arm.

Do I have to have the axel jacked up high or low to release the bind?

Now...update. I pounded the crud out of the axel side bolt. I got it to moved to the point that I can no longer hit it (the tip is inside the control arm). I can't get it to pull through anymore by prying, and worse yet. It looks like it is not lined up to be pushed back through. I am pounding the snot out of it to try and get it back through but it is binding on the the inside of the control arm.

Do I have to have the axel jacked up high or low to release the bind?

#9

Senior Member

Join Date: Jul 2009

Location: Yelm Wa

Posts: 822

Likes: 0

Received 1 Like

on

1 Post

Year: 1990

Model: Cherokee

Engine: 4.0

After you have the nut off put vise grips on the bolt head and tap with a punch and pull with the vise grips works. As for the axle end, i gave up on it am going to have to cut mine off with my mini cut off wheel.

#10

Seasoned Member

Join Date: Aug 2009

Location: DeKalb, IL

Posts: 262

Likes: 0

Received 1 Like

on

1 Post

Year: 2008 JKU (my XJ is long gone)

Engine: 3.8

if you are going to replace the bushings why not use some good heat and burn out the old ones. Then get the bolts out. Mine sucked too but I used a beefy impact and just worked it until they came loose from the sleeves.

#11

Member

Thread Starter

Well, I got the bolt back through using a ball joint press. And I torqued everything down tight all around. Upper control arms are going to have to stay. I will replace the lower control arms when the Ironman Adjustables come in. I will replace a torn drivers side tie end rod and get a professional alignment. If this doesn't cure my death wobble, I will attack the Upper Control Arms again. But not worth our only vehicle undrivable.

Thanks for your help, guys.

Thanks for your help, guys.

#12

Senior Member

Join Date: May 2009

Location: Middlesex County CT

Posts: 559

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1993

Model: Cherokee

Engine: 4.0 H.O

I would just have cut off the bolt on either side of the bushing. Drop the CA out and then pound out the remaining bolt pieces.

If my Jeep has taught me anything it's that it's better to just cut off any stubborn rusty bolts. I'd rather spend a few bucks on new bolts than spend a few hours trying to get the old ones out.

If my Jeep has taught me anything it's that it's better to just cut off any stubborn rusty bolts. I'd rather spend a few bucks on new bolts than spend a few hours trying to get the old ones out.

#14

CF Veteran

lol and a torch and grinder cutoff wheels...and patience. One thing when I reasemble everything I put generous amounts of antiseize or axle grease on all the nuts and bolts for down the line when you have to take it apart again cuz you know you will.

#15

Now...update. I pounded the crud out of the axel side bolt. I got it to moved to the point that I can no longer hit it (the tip is inside the control arm). I can't get it to pull through anymore by prying, and worse yet. It looks like it is not lined up to be pushed back through. I am pounding the snot out of it to try and get it back through but it is binding on the the inside of the control arm.

Do I have to have the axel jacked up high or low to release the bind?

Do I have to have the axel jacked up high or low to release the bind?

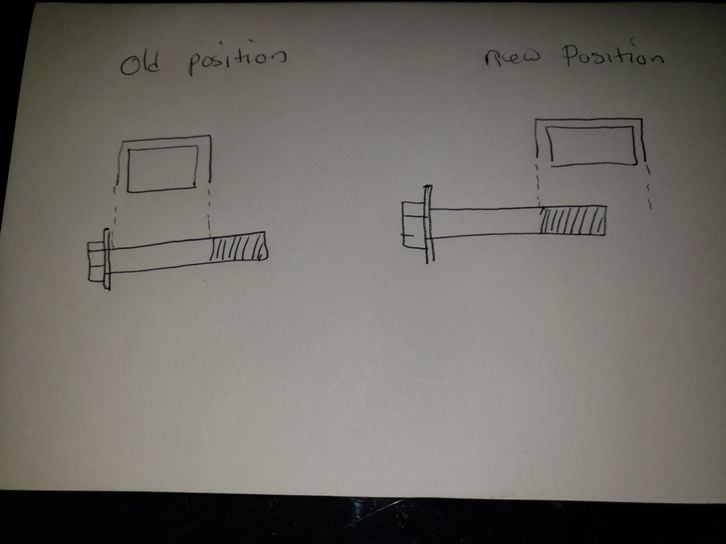

Mine are not rusted at all really. The bolt was sliding free with a few love taps from the hammer, and the nut came off cleanly with no struggle. Now that the bolt is inside the control arm, it stopped moving where it sits in the photo.

Honestly, it feels like once the thread hit the inside edge of the control arm, it can't slide as freely, and now it's stuck.

I'd really appreciate any tips short of cutting the bolt.