Welding thread!!!!

#2657

CF Veteran

Join Date: Oct 2018

Location: United Kingdom

Posts: 1,576

Received 278 Likes

on

242 Posts

Year: 1995 RHD

Model: Cherokee (XJ)

Engine: 4.0l

It was. The plan was to sort by the rear latch and paint the floor to prevent further damage. As I used a wire wheel to pull up surface rust it just started to make holes. It's better to find and remove rust then to paint over.

#2658

Senior Member

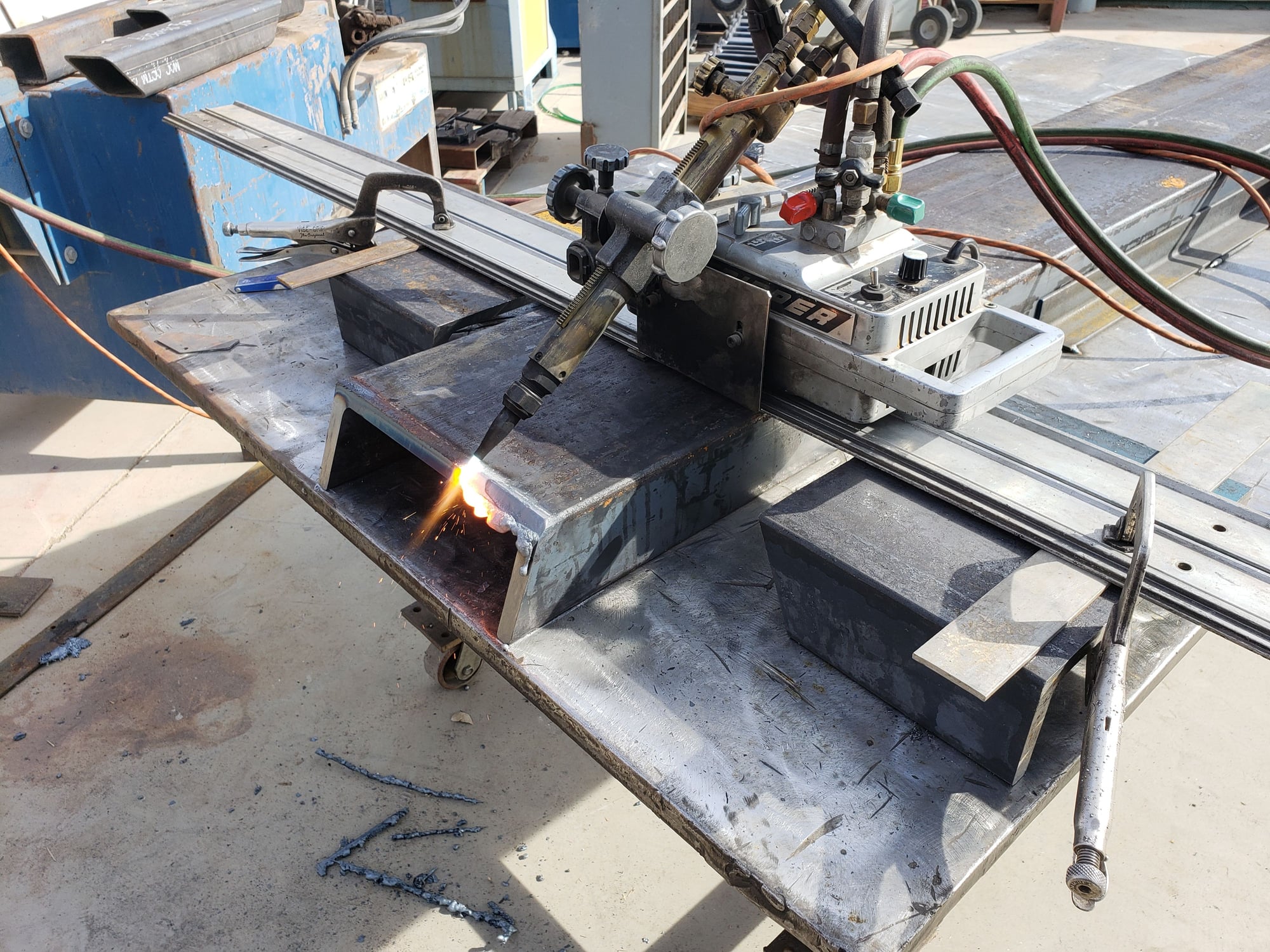

I made a drawer for my welding cart today and spot welded it together. I still have to put a handle on it and paint it.

#2660

Senior Member

#2662

Senior Member

I am about to do an 8.8 swap and ordered a truss for my new axle. When welding on the axle how much can I do without risking bending the axle from the heat? would it be like weld two inches then let cool then two more? I am using a hobart 140 if that helps.

one other question, sometimes the wire hangs up in the tip and then backs up on the machine requiring me to cut the wire and re thread it. i usually take a piece of wire and push it back and forth in the tip to clean it out first. why does that happen and what can i do to prevent it?

thanks!

one other question, sometimes the wire hangs up in the tip and then backs up on the machine requiring me to cut the wire and re thread it. i usually take a piece of wire and push it back and forth in the tip to clean it out first. why does that happen and what can i do to prevent it?

thanks!

#2663

CF Veteran

as for welding the truss, start with some tacking and tack opposite to keep it as cool as you can. start in the middle and work your way out. i use an air nozzle to cool it slowly. wet rag works too, but i like using compressed air. i don't blow it directly on the welds, but around it on the base metal.

then start stitching in the same pattern, letting it cool off between welds. you should be fine. the axle tubes are much thicker and takes more to heat them up to warping stage.

as for your mig tip, i use tip gel of some sorts. any will work, some even use pam spray. you only need a bit, not a gooping amount. i tap my tip in the gel when it's hot. that's all you need. i can take a pic of my gel. it's not a large tub, it will last you a very long time.

then start stitching in the same pattern, letting it cool off between welds. you should be fine. the axle tubes are much thicker and takes more to heat them up to warping stage.

as for your mig tip, i use tip gel of some sorts. any will work, some even use pam spray. you only need a bit, not a gooping amount. i tap my tip in the gel when it's hot. that's all you need. i can take a pic of my gel. it's not a large tub, it will last you a very long time.

#2664

CF Veteran

Join Date: Oct 2018

Location: United Kingdom

Posts: 1,576

Received 278 Likes

on

242 Posts

Year: 1995 RHD

Model: Cherokee (XJ)

Engine: 4.0l

one other question, sometimes the wire hangs up in the tip and then backs up on the machine requiring me to cut the wire and re thread it. i usually take a piece of wire and push it back and forth in the tip to clean it out first. why does that happen and what can i do to prevent it?

thanks!

thanks!

#2665

Seasoned Member

^this

I have the same welder and it comes with the .030" wire. I went to the .035 wire and was having all sorts of issues. Switched to the correct tip, and was good to go. I was using flux wire though.

I have the same welder and it comes with the .030" wire. I went to the .035 wire and was having all sorts of issues. Switched to the correct tip, and was good to go. I was using flux wire though.

#2666

Senior Member

thanks guys. i am running .03 wire with matching tip. no gel or pam. how often do you apply the lube? before a welding event?

#2667

Seasoned Member

#2668

CF Veteran

i just dip my hot tip in the gel and good for a little while. if i notice more splatter sticking to the tip, i just dip it again.

#2669

Senior Member

I installed a LCA lowering kit and on my first attempt of joining .25" steel i burned a hole through the thin body metal. so what i did was turn down the heat and weld a few passes to the unibody itself next to the .25" metal. then i set the heat higher and joined the thicker metal to the frame over the preweld. is this how its normally done or is there a better better method?

BTW, i am not particularly proud of that weld it was rather difficult to do under the jeep and upside down. very little room especially with the hood, grounding clamp, and wand. I am open to any position sugestions as well. thanks guys!

#2670

Senior Member