P0740 trans code + tests results

#1

Member

Thread Starter

Join Date: Jul 2009

Location: Los Angeles CA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0L 6 Cyl

Sorry, I already replied to a previous thread but decided to post my own...

Transmission was rebuilt after 90kmiles. Then rebuilt again (and torque converter changed) after another 100kmiles. Don't know what the codes were then - I was not working on my jeep at this time. The jeep is a 98 sport, AW4, with 334kmiles. Working great otherwise...

Well, so much for my "fix". I had the P0700 and P0740 come back for the past 2 months or so now.

I have used the method provided by Ken in quotes below.

Here are the results of the tests (all tests on TCM plug):

- TCM ground circuit at cavity 24: no resistance.

- Brake lamp switch: little resistance at about 2 ohms (tester fluctuating a lot before settling). No change when depressing the brake pedal.

- Solenoid circuits: 14 omhs on C. 15 ohms on the other 2.

- TPS: no checked. (replaced with a Mopar unit less than a year ago).

Again, the behavior is the following:

"Problem" going out of 1st when cold (it has been doing this for ever so I was led to think that it is normal...); it feels like the car doesn't want to shift out of 1st. It does this until temp reaches maybe 110 or so (or a few shifts) and then it shift out of 1st very well. No issue ever shifting to 3rd. Typically after several stop and go in traffic, it then looks like it doesn't shift into 4th. I can tell this issue is coming because the RPM drop from 1 to 2 and 2 to 3 is very minimal. A few stop and go later, while in 3rd, RPM keep going up. I can drive the jeep at almost 3k RPM for 60mph. I am not really sure if it is actually the torque converter not locking up or if it is not shifting into 4th.

I can tell several times that the converter doesn't lock up since removing my foot from the gas shows a significant and immediate drop in RPM. When the TC locks up, depressing the brake pedal increases slightly the RPM.

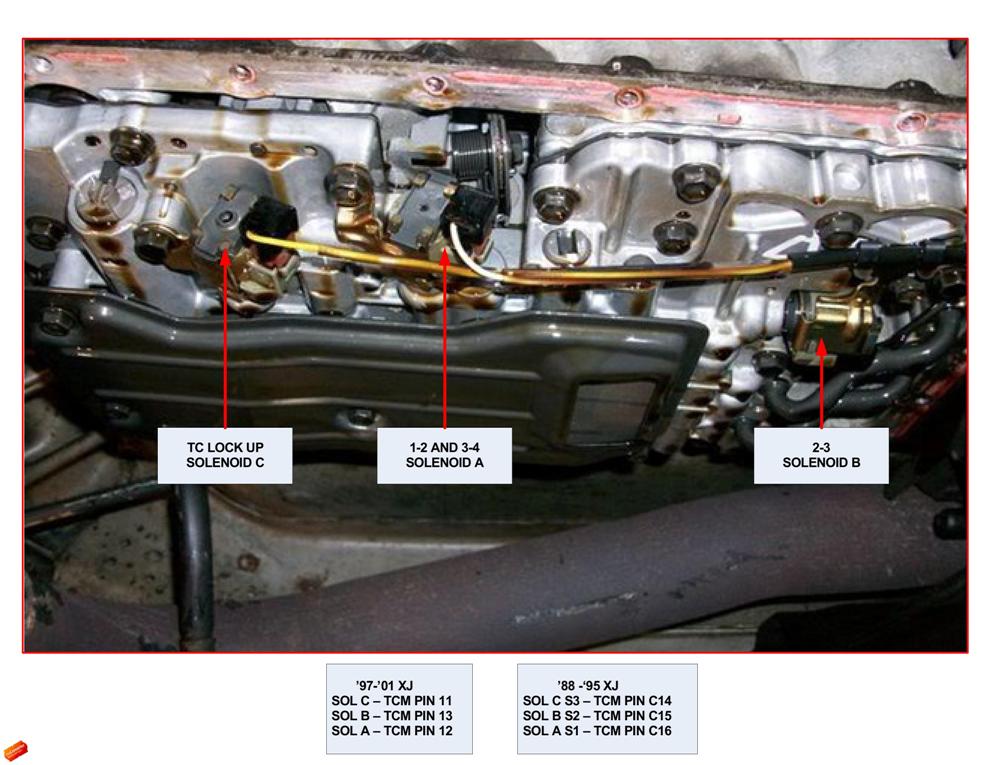

I changed the C solenoid about 2 years ago after getting a P0743.

This transmission issue seems to be reoccuring about every 6 months..

I am wondering if the solenoid (1 or 2 can't remember) that controls shifting 1 to 2 and 3 to 4 could be at fault. Again, resistance tested when cold is normal.

I use the correct fluid, which is bright red. Due to those issues in the past 2 years I have drained and refilled several times. Level may be slightly high.

Last (but maybe not least), the solenoid connectors are broken (at least 2 of the 3) and are held in place with zip ties (Yes I know... but last time I dropped the pan they were still holding the connectors very tight).

Besides testing the TPS (which I will do next week when getting an analog multitester), draining a little bit of fluid to put it at a lower level, what would you suggest I test next?

Sorry for the long post...

Many thanks.

Marc

<<

You may have a bad brake lamp switch, bad TPS signal to the TCM, or wiring from the TCM to the Lock-Up solenoid.

~~~~~~~~~~~

Tests:

You'll need a digital Volt/Ohmmeter.

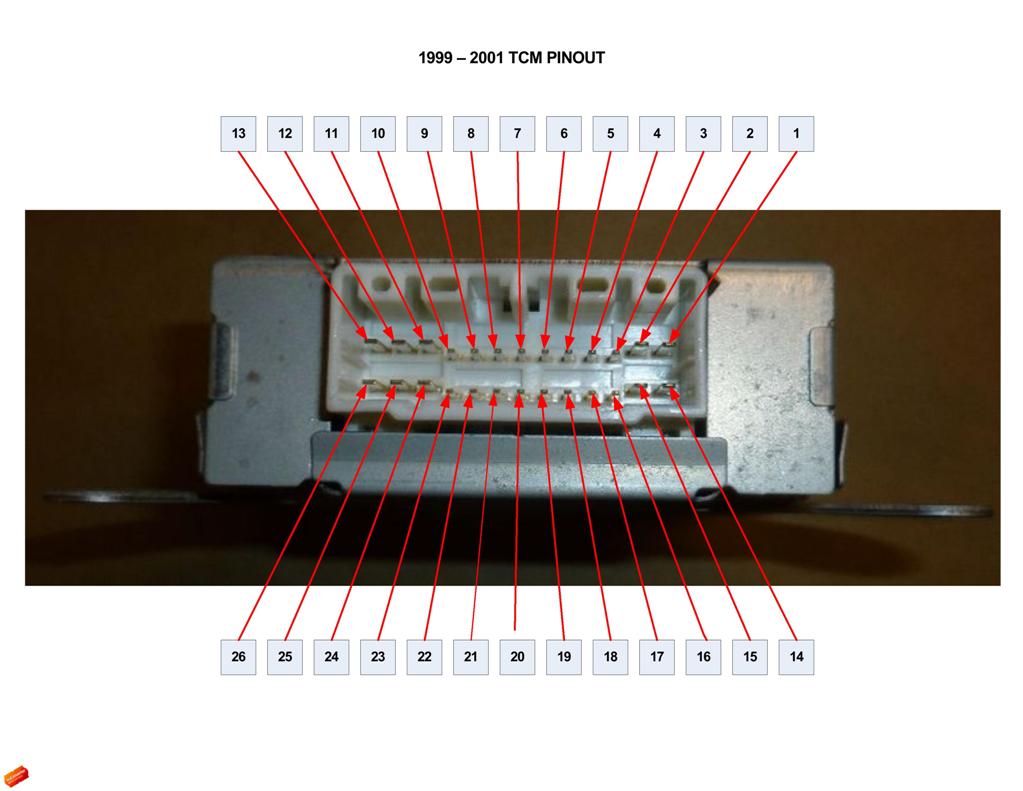

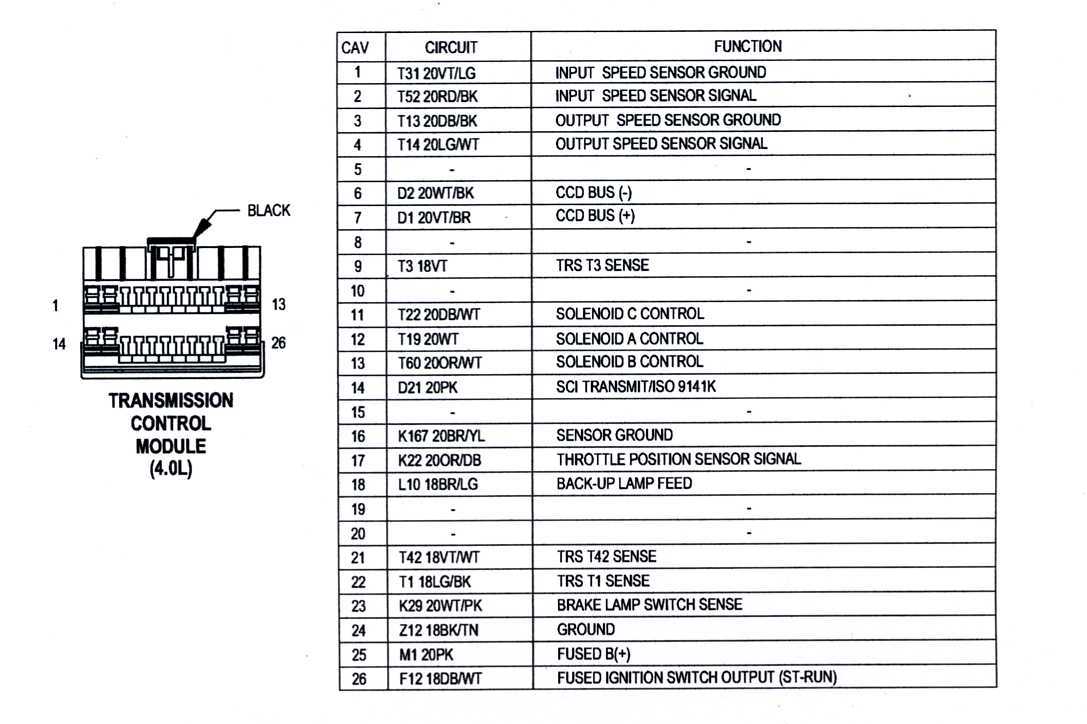

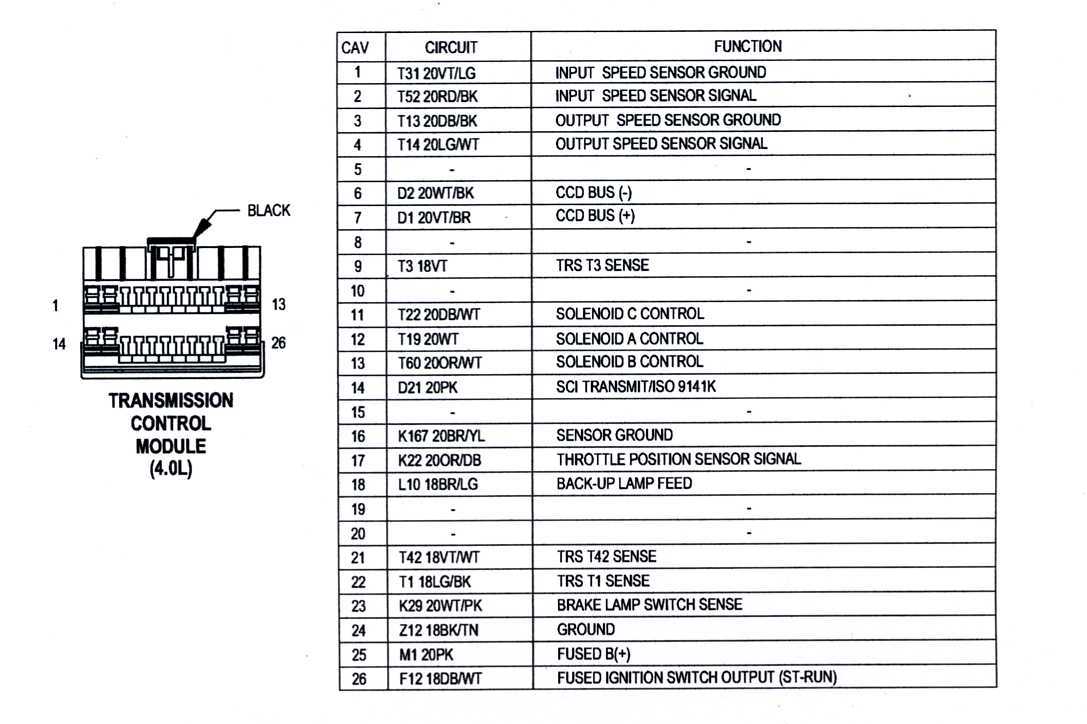

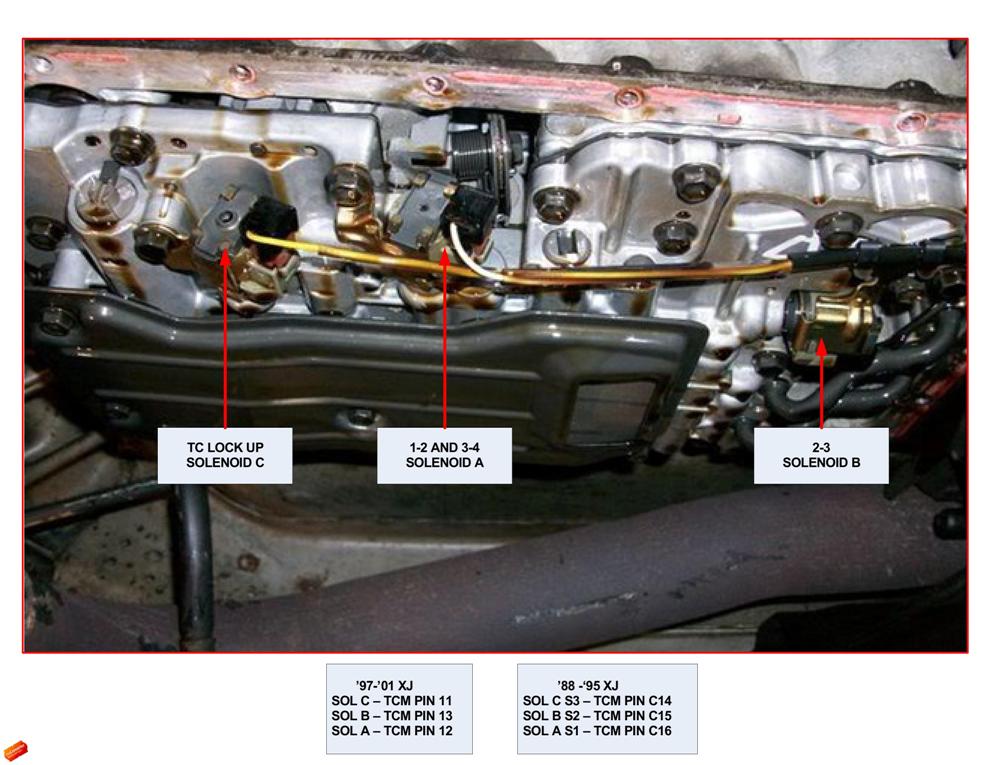

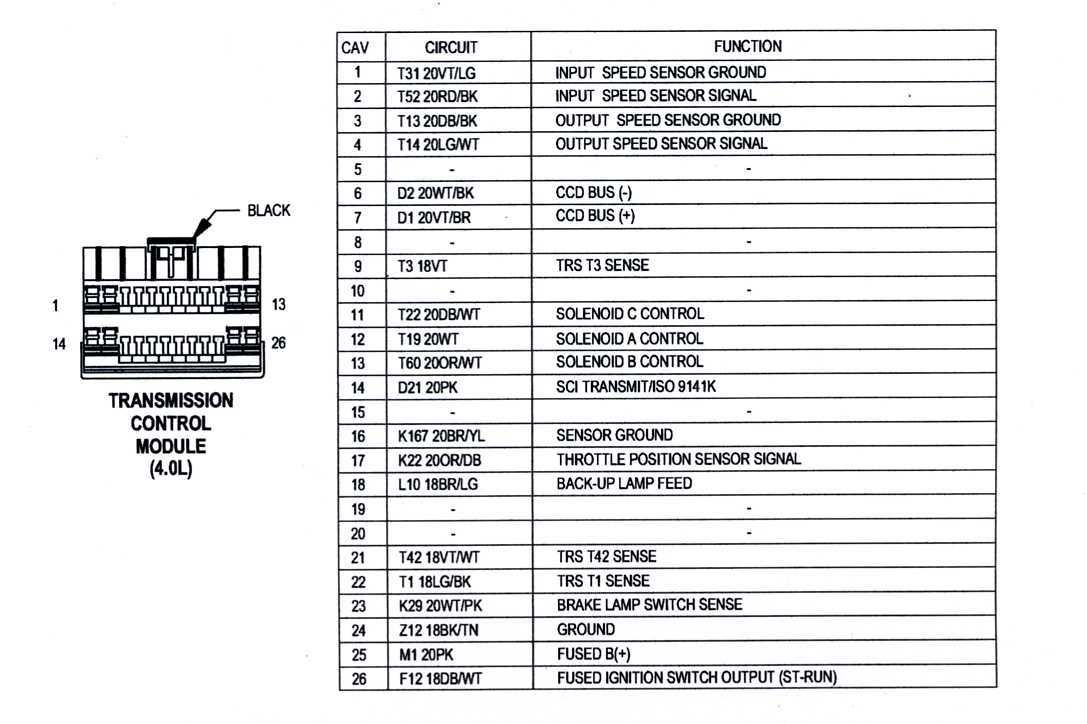

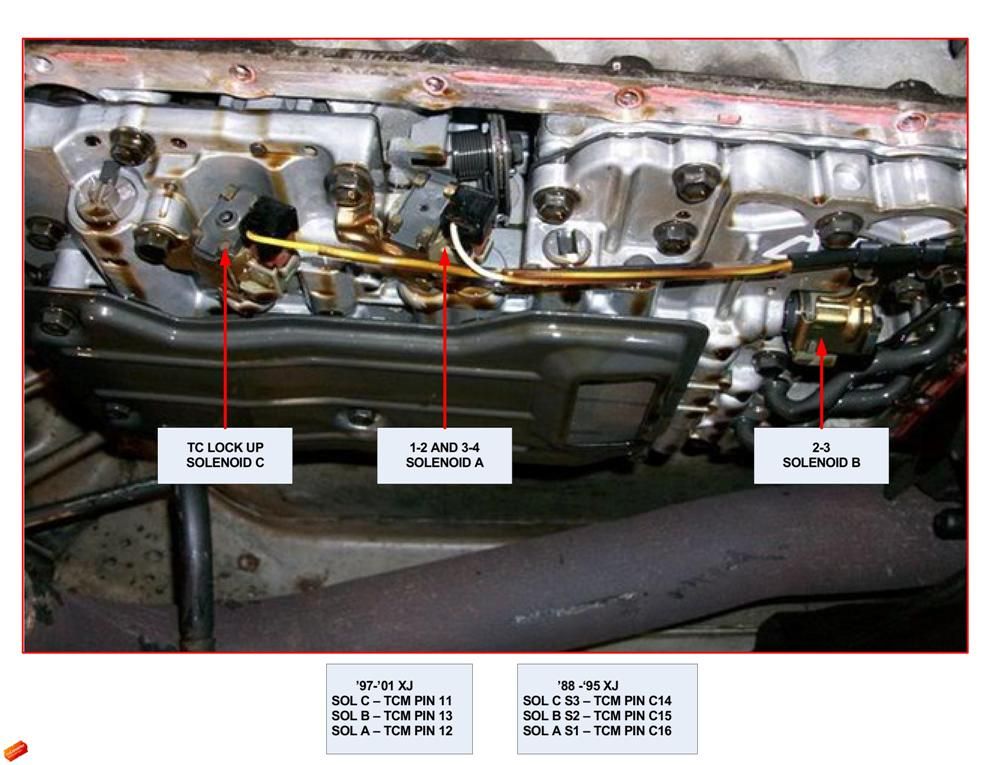

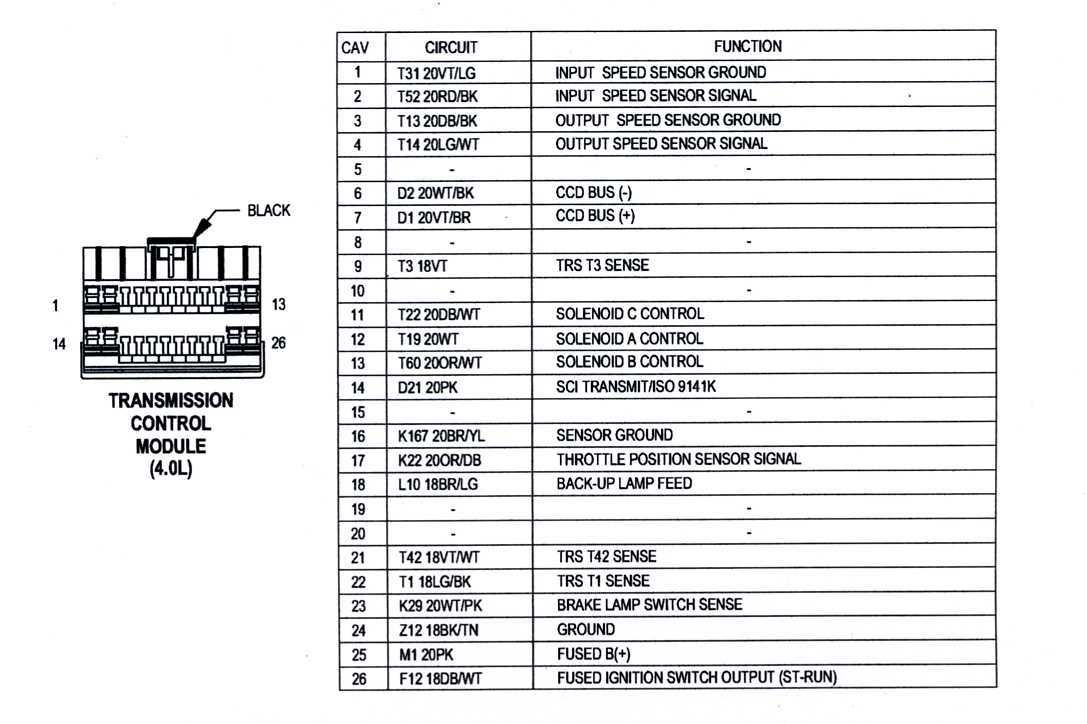

Refer to the TCM connector pin-out below.

Preliminary

Disconnect battery ground cable at battery. Leave disconnected during the Ohmmeter checks.

Access TCM and unplug the connector.

Check the TCM ground circuit by probing pin cavity 24 (+) to a good chassis ground under the dash. You should read continuity, but no more than 1.0 Ohm resistance. If you see high resistance, the TCM ground point connection should be checked/cleaned. The TCM is grounded at the coil mount bracket stud(s). Two small wire ring terminals and a battery ground cable. Remove and clean the two small ring terminals. Reconnect and read the resistance again.

Brake Lamp Switch

Probe pin cavity 23 (+) to cavity 24 (-). You should see continuity. Move the brake pedal in and out and see if the reading changes. If so, replace the switch. If you see resistance of more than 5.0 Ohms at any time, replace the switch.

Solenoid 'C' circuit wiring

Measure the resistance between cavity 11 (+) and 24 (-). You should see 11 to 15 Ohms resistance (solenoid resistance spec). With a new solenoid installed it should be within spec. If not there may be a wiring fault between the TCM and the solenoid.

TPS Checks

If any fault was found and corrected in the above checks you may not want to be bothered with this check.

To proceed,

Reconnect the battery ground cable at the battery.

You'll be checking the TPS output voltage to the TCM.

Set voltmeter to 20 VDC scale.

Turn ignition switch to ON (run) without starting the engine.

Measure the TPS input voltage by probing cavity 17 (+) to cavity 16 (-). At idle you should read between .26 V and .95 V. While still connected, depress the gas pedal slowly to WOT and watch the Voltmeter. The voltage should increase smoothly to 4.49 volts, or less.

You may not have been experiencing TPS performance problems but the lack of good voltage to the TCM may cause your problem.

Completion

Disconnect the battery ground cable before reconnecting the TCM connector.

Tell us what you find. >>

Transmission was rebuilt after 90kmiles. Then rebuilt again (and torque converter changed) after another 100kmiles. Don't know what the codes were then - I was not working on my jeep at this time. The jeep is a 98 sport, AW4, with 334kmiles. Working great otherwise...

Well, so much for my "fix". I had the P0700 and P0740 come back for the past 2 months or so now.

I have used the method provided by Ken in quotes below.

Here are the results of the tests (all tests on TCM plug):

- TCM ground circuit at cavity 24: no resistance.

- Brake lamp switch: little resistance at about 2 ohms (tester fluctuating a lot before settling). No change when depressing the brake pedal.

- Solenoid circuits: 14 omhs on C. 15 ohms on the other 2.

- TPS: no checked. (replaced with a Mopar unit less than a year ago).

Again, the behavior is the following:

"Problem" going out of 1st when cold (it has been doing this for ever so I was led to think that it is normal...); it feels like the car doesn't want to shift out of 1st. It does this until temp reaches maybe 110 or so (or a few shifts) and then it shift out of 1st very well. No issue ever shifting to 3rd. Typically after several stop and go in traffic, it then looks like it doesn't shift into 4th. I can tell this issue is coming because the RPM drop from 1 to 2 and 2 to 3 is very minimal. A few stop and go later, while in 3rd, RPM keep going up. I can drive the jeep at almost 3k RPM for 60mph. I am not really sure if it is actually the torque converter not locking up or if it is not shifting into 4th.

I can tell several times that the converter doesn't lock up since removing my foot from the gas shows a significant and immediate drop in RPM. When the TC locks up, depressing the brake pedal increases slightly the RPM.

I changed the C solenoid about 2 years ago after getting a P0743.

This transmission issue seems to be reoccuring about every 6 months..

I am wondering if the solenoid (1 or 2 can't remember) that controls shifting 1 to 2 and 3 to 4 could be at fault. Again, resistance tested when cold is normal.

I use the correct fluid, which is bright red. Due to those issues in the past 2 years I have drained and refilled several times. Level may be slightly high.

Last (but maybe not least), the solenoid connectors are broken (at least 2 of the 3) and are held in place with zip ties (Yes I know... but last time I dropped the pan they were still holding the connectors very tight).

Besides testing the TPS (which I will do next week when getting an analog multitester), draining a little bit of fluid to put it at a lower level, what would you suggest I test next?

Sorry for the long post...

Many thanks.

Marc

<<

You may have a bad brake lamp switch, bad TPS signal to the TCM, or wiring from the TCM to the Lock-Up solenoid.

~~~~~~~~~~~

Tests:

You'll need a digital Volt/Ohmmeter.

Refer to the TCM connector pin-out below.

Preliminary

Disconnect battery ground cable at battery. Leave disconnected during the Ohmmeter checks.

Access TCM and unplug the connector.

Check the TCM ground circuit by probing pin cavity 24 (+) to a good chassis ground under the dash. You should read continuity, but no more than 1.0 Ohm resistance. If you see high resistance, the TCM ground point connection should be checked/cleaned. The TCM is grounded at the coil mount bracket stud(s). Two small wire ring terminals and a battery ground cable. Remove and clean the two small ring terminals. Reconnect and read the resistance again.

Brake Lamp Switch

Probe pin cavity 23 (+) to cavity 24 (-). You should see continuity. Move the brake pedal in and out and see if the reading changes. If so, replace the switch. If you see resistance of more than 5.0 Ohms at any time, replace the switch.

Solenoid 'C' circuit wiring

Measure the resistance between cavity 11 (+) and 24 (-). You should see 11 to 15 Ohms resistance (solenoid resistance spec). With a new solenoid installed it should be within spec. If not there may be a wiring fault between the TCM and the solenoid.

TPS Checks

If any fault was found and corrected in the above checks you may not want to be bothered with this check.

To proceed,

Reconnect the battery ground cable at the battery.

You'll be checking the TPS output voltage to the TCM.

Set voltmeter to 20 VDC scale.

Turn ignition switch to ON (run) without starting the engine.

Measure the TPS input voltage by probing cavity 17 (+) to cavity 16 (-). At idle you should read between .26 V and .95 V. While still connected, depress the gas pedal slowly to WOT and watch the Voltmeter. The voltage should increase smoothly to 4.49 volts, or less.

You may not have been experiencing TPS performance problems but the lack of good voltage to the TCM may cause your problem.

Completion

Disconnect the battery ground cable before reconnecting the TCM connector.

Tell us what you find. >>

#2

Member

Thread Starter

Join Date: Jul 2009

Location: Los Angeles CA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0L 6 Cyl

Anybody? Any suggestions?

I failed to mention also that the last transmission shop I took it to couldn't figure out the issue. Said it did not need a rebuild but still replaced the valve body. A friend mechanic suggested replacing the NSS so I did that. Again, all that was a year ago. Symptoms did not stop after all this money wasted; however it stopped after I cleaned up the battery posts/terminals and all the transmission related contacts. Did that again this past weekend but no luck.

I failed to mention also that the last transmission shop I took it to couldn't figure out the issue. Said it did not need a rebuild but still replaced the valve body. A friend mechanic suggested replacing the NSS so I did that. Again, all that was a year ago. Symptoms did not stop after all this money wasted; however it stopped after I cleaned up the battery posts/terminals and all the transmission related contacts. Did that again this past weekend but no luck.

Last edited by mlepesant; 08-15-2014 at 09:52 AM. Reason: added title

#4

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Anybody? Any suggestions?

I failed to mention also that the last transmission shop I took it to couldn't figure out the issue. Said it did not need a rebuild but still replaced the valve body. A friend mechanic suggested replacing the NSS so I did that. Again, all that was a year ago. Symptoms did not stop after all this money wasted; however it stopped after I cleaned up the battery posts/terminals and all the transmission related contacts. Did that again this past weekend but no luck.

I failed to mention also that the last transmission shop I took it to couldn't figure out the issue. Said it did not need a rebuild but still replaced the valve body. A friend mechanic suggested replacing the NSS so I did that. Again, all that was a year ago. Symptoms did not stop after all this money wasted; however it stopped after I cleaned up the battery posts/terminals and all the transmission related contacts. Did that again this past weekend but no luck.

The brake lamp switch should read continuity when the brake pedal is released and read open when the pedal is depressed. Use 200 Ohm scale on your Ohmmeter.

What kind of multimeter are you using? Hope it's not an autoranging meter.

#6

Member

Thread Starter

Join Date: Jul 2009

Location: Los Angeles CA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0L 6 Cyl

#7

Member

Thread Starter

Join Date: Jul 2009

Location: Los Angeles CA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0L 6 Cyl

Test the TPS voltage at the TCM connector per the instructions.

The brake lamp switch should read continuity when the brake pedal is released and read open when the pedal is depressed. Use 200 Ohm scale on your Ohmmeter.

What kind of multimeter are you using? Hope it's not an autoranging meter.

The brake lamp switch should read continuity when the brake pedal is released and read open when the pedal is depressed. Use 200 Ohm scale on your Ohmmeter.

What kind of multimeter are you using? Hope it's not an autoranging meter.

Trending Topics

#8

Member

Thread Starter

Join Date: Jul 2009

Location: Los Angeles CA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0L 6 Cyl

Test the TPS voltage at the TCM connector per the instructions.

The brake lamp switch should read continuity when the brake pedal is released and read open when the pedal is depressed. Use 200 Ohm scale on your Ohmmeter.

What kind of multimeter are you using? Hope it's not an autoranging meter.

The brake lamp switch should read continuity when the brake pedal is released and read open when the pedal is depressed. Use 200 Ohm scale on your Ohmmeter.

What kind of multimeter are you using? Hope it's not an autoranging meter.

On the 200 ohm scale.

- TCM ground cavity 24: 00.5 (tested an hour later. same reading)

Cleaned ring terminals. Same reading after.

- Brake lamp switch: pin 23 to 24

00.7 and 94.2 when pedal pressed.

On continuity setting, continuity when pedal not pressed, no continuity when pedal is pressed.

Replaced brake lamp switch. Same readings after.

Tested about one hour later. 00.9 and 121.0 when pedal pressed.

- Solenoid C at the TCM connector

pin 11: 17

Pin 12: 16.5

Pin 13: 16.5

Tested about one hour later:

Pin 11: 15.5

Pin 12: 14.9

Pin 13: 15.0

At the plug coming from trans:

top row, left to right:

16.2

15.6

15.7

- TPS check:

Pin 17 to 16:

Idle 0.84 WOP: 4.03

Voltage increases smoothly with the analog multimeter.

Took car for test, and the CEL came back on pretty quickly after a few stop and go. Shifting 1 to 2 and 2 to 3 are normal. 3 to 4 is ok and it locks up for the first 2 or 3 times and then it doesn't seem to shift to 4 and/or lockup and the cel comes on.

I inspected as much wiring as I could but didn't find anything abnormal.

What else do you suggest I test and what would you conclude from those readings?

Thanks for your help.

#9

Member

Thread Starter

Join Date: Jul 2009

Location: Los Angeles CA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0L 6 Cyl

I also tested the Input and Output speed sensors at the TCM connector. Both read close to 700 ohms. (694-695)

#10

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Here's some basic diagnostics for P0740:

NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

Verify the brake switch input to the TCM is working correctly.

Perform the shift lever position test and adjust the linkage if necessary.

When monitored: Continuously with the Torque Convertor Clutch Solenoid (Solenoid

C) energized.

When set: When the solenoid is energized and the Engine RPM does not equal the

Transmissionís Input Speed RPM or when the solenoid is deenergized and the Engine

RPM equals Transmission input RPM.

This is the When monitored / When set conditions for DTC P0740.

Test drive the vehicle.

Maintain a steady speed of 55 MPH for 30 seconds.

Bring the vehicle slowly to a complete stop.

NOTE: Check shift patterns while the vehicle is upshifting and downshifting.

Did Solenoid C (TCC) engage properly during the test drive?

~~~~~~~~

You could have a sticky solenoid valve and still have 'within spec' resistances.

If you are having problems shifting from 3rd to 4th, maybe solenoid A is sticky.

It seems your resistances are on the high side, or inconsistant, for all readings. Maybe you should try a different meter before progressing any further.

You may want to check the transmission range sensor (NSS) inputs to the TCM.

Refer to the pinout.

This is a voltage check.

With key to RUN. Note: Power for these checks comes from fuse F10 in the JB (Start-Run circuit).

Measure the voltage at the battery for reference.

Shift transmission to Drive (D),

Touch pin cav 22 (+) and pin cav 24 (-). You should see battery voltage.

Shift to 3rd gear (3),

Touch pin cav 9 (+) and pin cav 24 (-). You should see battery voltage.

Shift to 1-2,

Touch pin cav 21 (+) and pin cav 24 (-). You should see battery voltage.

~~~~~~~

I'm wondering if that replacement Torque Converter is any good. Was it a used (in service) TC, or a rebuilt one?

~~~~~~~

NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

Verify the brake switch input to the TCM is working correctly.

Perform the shift lever position test and adjust the linkage if necessary.

When monitored: Continuously with the Torque Convertor Clutch Solenoid (Solenoid

C) energized.

When set: When the solenoid is energized and the Engine RPM does not equal the

Transmissionís Input Speed RPM or when the solenoid is deenergized and the Engine

RPM equals Transmission input RPM.

This is the When monitored / When set conditions for DTC P0740.

Test drive the vehicle.

Maintain a steady speed of 55 MPH for 30 seconds.

Bring the vehicle slowly to a complete stop.

NOTE: Check shift patterns while the vehicle is upshifting and downshifting.

Did Solenoid C (TCC) engage properly during the test drive?

~~~~~~~~

You could have a sticky solenoid valve and still have 'within spec' resistances.

If you are having problems shifting from 3rd to 4th, maybe solenoid A is sticky.

It seems your resistances are on the high side, or inconsistant, for all readings. Maybe you should try a different meter before progressing any further.

You may want to check the transmission range sensor (NSS) inputs to the TCM.

Refer to the pinout.

This is a voltage check.

With key to RUN. Note: Power for these checks comes from fuse F10 in the JB (Start-Run circuit).

Measure the voltage at the battery for reference.

Shift transmission to Drive (D),

Touch pin cav 22 (+) and pin cav 24 (-). You should see battery voltage.

Shift to 3rd gear (3),

Touch pin cav 9 (+) and pin cav 24 (-). You should see battery voltage.

Shift to 1-2,

Touch pin cav 21 (+) and pin cav 24 (-). You should see battery voltage.

~~~~~~~

I'm wondering if that replacement Torque Converter is any good. Was it a used (in service) TC, or a rebuilt one?

~~~~~~~

#11

Member

Thread Starter

Join Date: Jul 2009

Location: Los Angeles CA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0L 6 Cyl

Thanks Ken.

I will retest again, trying to find a different multitester. I am having difficulties probing some cavities on the TCM connector (I am wondering if the connectors inside the cavities can get damaged...).

I will check also the NSS inputs per your instructions.

According to the invoice (2006) the torque converter was a rebuilt unit. That would be my 3rd rebuild in 335k. Again, at this time it was maintained regularly but I was not working on my jeep and therefore didn't pay attention to what was done. I don't even know what code was there.

I did a test drive last night, disconnecting the TCM and shifting manually. It shifts great from 1-2 to 3, the shift from 3 to D is not as obvious but I could feel it. Downshifting was more obvious. However I am not certain that OD engages in manual mode (meaning I don't know if in manual shift the converter is supposed to lock up).

Quick question: could engine performance have an effect on the TCC lock up? I know that my timing chain is loose (not skipping); much more slack than the "allowed" amount. I do have the timing set ready but didn't get a chance to get it done. Could a loose timing chain affect timing to a point where it would have an impact on engine rpm vs transmission speed?

Thanks again for all the help. I am out of town until the weekend, so that will be my next update.

I will retest again, trying to find a different multitester. I am having difficulties probing some cavities on the TCM connector (I am wondering if the connectors inside the cavities can get damaged...).

I will check also the NSS inputs per your instructions.

According to the invoice (2006) the torque converter was a rebuilt unit. That would be my 3rd rebuild in 335k. Again, at this time it was maintained regularly but I was not working on my jeep and therefore didn't pay attention to what was done. I don't even know what code was there.

I did a test drive last night, disconnecting the TCM and shifting manually. It shifts great from 1-2 to 3, the shift from 3 to D is not as obvious but I could feel it. Downshifting was more obvious. However I am not certain that OD engages in manual mode (meaning I don't know if in manual shift the converter is supposed to lock up).

Quick question: could engine performance have an effect on the TCC lock up? I know that my timing chain is loose (not skipping); much more slack than the "allowed" amount. I do have the timing set ready but didn't get a chance to get it done. Could a loose timing chain affect timing to a point where it would have an impact on engine rpm vs transmission speed?

Thanks again for all the help. I am out of town until the weekend, so that will be my next update.

Here's some basic diagnostics for P0740:

NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

Verify the brake switch input to the TCM is working correctly.

Perform the shift lever position test and adjust the linkage if necessary.

When monitored: Continuously with the Torque Convertor Clutch Solenoid (Solenoid

C) energized.

When set: When the solenoid is energized and the Engine RPM does not equal the

Transmissionís Input Speed RPM or when the solenoid is deenergized and the Engine

RPM equals Transmission input RPM.

This is the When monitored / When set conditions for DTC P0740.

Test drive the vehicle.

Maintain a steady speed of 55 MPH for 30 seconds.

Bring the vehicle slowly to a complete stop.

NOTE: Check shift patterns while the vehicle is upshifting and downshifting.

Did Solenoid C (TCC) engage properly during the test drive?

~~~~~~~~

You could have a sticky solenoid valve and still have 'within spec' resistances.

If you are having problems shifting from 3rd to 4th, maybe solenoid A is sticky.

It seems your resistances are on the high side, or inconsistant, for all readings. Maybe you should try a different meter before progressing any further.

You may want to check the transmission range sensor (NSS) inputs to the TCM.

Refer to the pinout.

This is a voltage check.

With key to RUN. Note: Power for these checks comes from fuse F10 in the JB (Start-Run circuit).

Measure the voltage at the battery for reference.

Shift transmission to Drive (D),

Touch pin cav 22 (+) and pin cav 24 (-). You should see battery voltage.

Shift to 3rd gear (3),

Touch pin cav 9 (+) and pin cav 24 (-). You should see battery voltage.

Shift to 1-2,

Touch pin cav 21 (+) and pin cav 24 (-). You should see battery voltage.

~~~~~~~

I'm wondering if that replacement Torque Converter is any good. Was it a used (in service) TC, or a rebuilt one?

~~~~~~~

NOTE: Low fluid level can be the cause of many transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the service information.

Verify the brake switch input to the TCM is working correctly.

Perform the shift lever position test and adjust the linkage if necessary.

When monitored: Continuously with the Torque Convertor Clutch Solenoid (Solenoid

C) energized.

When set: When the solenoid is energized and the Engine RPM does not equal the

Transmissionís Input Speed RPM or when the solenoid is deenergized and the Engine

RPM equals Transmission input RPM.

This is the When monitored / When set conditions for DTC P0740.

Test drive the vehicle.

Maintain a steady speed of 55 MPH for 30 seconds.

Bring the vehicle slowly to a complete stop.

NOTE: Check shift patterns while the vehicle is upshifting and downshifting.

Did Solenoid C (TCC) engage properly during the test drive?

~~~~~~~~

You could have a sticky solenoid valve and still have 'within spec' resistances.

If you are having problems shifting from 3rd to 4th, maybe solenoid A is sticky.

It seems your resistances are on the high side, or inconsistant, for all readings. Maybe you should try a different meter before progressing any further.

You may want to check the transmission range sensor (NSS) inputs to the TCM.

Refer to the pinout.

This is a voltage check.

With key to RUN. Note: Power for these checks comes from fuse F10 in the JB (Start-Run circuit).

Measure the voltage at the battery for reference.

Shift transmission to Drive (D),

Touch pin cav 22 (+) and pin cav 24 (-). You should see battery voltage.

Shift to 3rd gear (3),

Touch pin cav 9 (+) and pin cav 24 (-). You should see battery voltage.

Shift to 1-2,

Touch pin cav 21 (+) and pin cav 24 (-). You should see battery voltage.

~~~~~~~

I'm wondering if that replacement Torque Converter is any good. Was it a used (in service) TC, or a rebuilt one?

~~~~~~~

#12

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Thanks Ken.

I will retest again, trying to find a different multitester. I am having difficulties probing some cavities on the TCM connector (I am wondering if the connectors inside the cavities can get damaged...).

Yes, the pin cavities can be damaged if the meter probes are shoved in the cavities too hard.

Go to the thread below and scroll down to post #53. You'll see the safety pins I recommend for probing pin cavities (#1 or #2).

https://www.cherokeeforum.com/f2/gre...e-6558/index4/

I will check also the NSS inputs per your instructions.

According to the invoice (2006) the torque converter was a rebuilt unit. That would be my 3rd rebuild in 335k. Again, at this time it was maintained regularly but I was not working on my jeep and therefore didn't pay attention to what was done. I don't even know what code was there.

I did a test drive last night, disconnecting the TCM and shifting manually. It shifts great from 1-2 to 3, the shift from 3 to D is not as obvious but I could feel it. Downshifting was more obvious. However I am not certain that OD engages in manual mode (meaning I don't know if in manual shift the converter is supposed to lock up).

The manual shifting proves the transmission is mechanically good and that you have an electronic control issue. Don't look for lock up in manual mode.

Quick question: could engine performance have an effect on the TCC lock up? I know that my timing chain is loose (not skipping); much more slack than the "allowed" amount. I do have the timing set ready but didn't get a chance to get it done. Could a loose timing chain affect timing to a point where it would have an impact on engine rpm vs transmission speed?

I wouldn't think a loose timing chain would affect electronic control over the transmission. The TCM has its own speed/engine speed inputs form other sensors.

Thanks again for all the help. I am out of town until the weekend, so that will be my next update.

I will retest again, trying to find a different multitester. I am having difficulties probing some cavities on the TCM connector (I am wondering if the connectors inside the cavities can get damaged...).

Yes, the pin cavities can be damaged if the meter probes are shoved in the cavities too hard.

Go to the thread below and scroll down to post #53. You'll see the safety pins I recommend for probing pin cavities (#1 or #2).

https://www.cherokeeforum.com/f2/gre...e-6558/index4/

I will check also the NSS inputs per your instructions.

According to the invoice (2006) the torque converter was a rebuilt unit. That would be my 3rd rebuild in 335k. Again, at this time it was maintained regularly but I was not working on my jeep and therefore didn't pay attention to what was done. I don't even know what code was there.

I did a test drive last night, disconnecting the TCM and shifting manually. It shifts great from 1-2 to 3, the shift from 3 to D is not as obvious but I could feel it. Downshifting was more obvious. However I am not certain that OD engages in manual mode (meaning I don't know if in manual shift the converter is supposed to lock up).

The manual shifting proves the transmission is mechanically good and that you have an electronic control issue. Don't look for lock up in manual mode.

Quick question: could engine performance have an effect on the TCC lock up? I know that my timing chain is loose (not skipping); much more slack than the "allowed" amount. I do have the timing set ready but didn't get a chance to get it done. Could a loose timing chain affect timing to a point where it would have an impact on engine rpm vs transmission speed?

I wouldn't think a loose timing chain would affect electronic control over the transmission. The TCM has its own speed/engine speed inputs form other sensors.

Thanks again for all the help. I am out of town until the weekend, so that will be my next update.

#13

Member

Thread Starter

Join Date: Jul 2009

Location: Los Angeles CA

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0L 6 Cyl

Thanks Ken. Yes i have been using your safety pin trick. Made it much easier but i was still struggling a couple of times. The cavities are one thing i will inspect, just to make sure they are not damaged. Top and bottom rows have actually 2 cavities each. A small one and a larger one. Which one needs to be probed?

#14

Beach Bum

I read a number of posts that say the AW4 does not take well to being 'rebuilt'.

Why, I do not know. Is there truth to it? I do not know.

Is my post helpful? No

I do not believe everything I read, just thought I'd share what I came across researching the AW4.

Why, I do not know. Is there truth to it? I do not know.

Is my post helpful? No

I do not believe everything I read, just thought I'd share what I came across researching the AW4.

#15

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Thanks Ken. Yes i have been using your safety pin trick. Made it much easier but i was still struggling a couple of times. The cavities are one thing i will inspect, just to make sure they are not damaged. Top and bottom rows have actually 2 cavities each. A small one and a larger one. Which one needs to be probed?

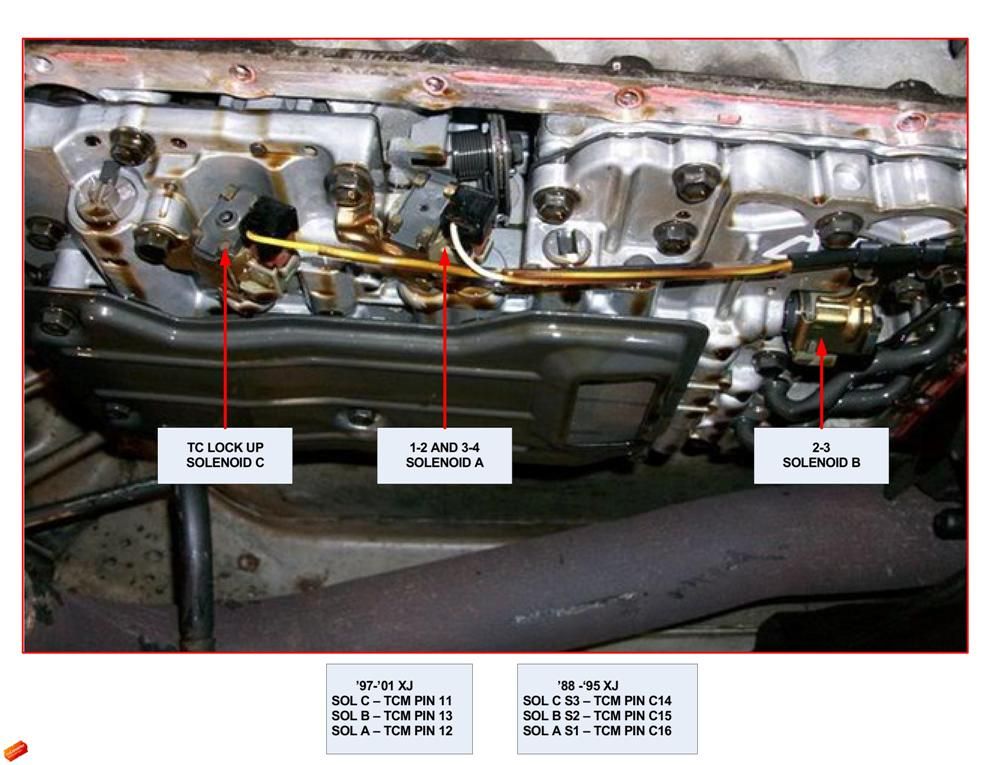

Ref which cavity to probe: I ran into this the other day with a member getting confused on which pin cavity to use. Well, the TCM connector pinout is wrong. There are, in fact 26 pin cavities, but the image of the connector is wrong. Below is an image of the TCM pins that I have numbered, 1 thru 26.

The connector is the mirror image of the TCM. If still dicked up, print the image and hold it up to a mirror - that will be the connector.