99 4.o kncking/scraping

#31

Seasoned Member

Thread Starter

so add about 100 lbs or so for a 5.2? yeah it would be great to build it with a big hemi, I wonder about just stripping the wiring and going with an old dodge small block , carbureted and built something like a 340? I know the new engines are better but I have to be realistic what I or any other normal person can afford and do. But most likely I'm going to fix the main bearings or rods , I'm thinking main bearings since the oil pressure gauge has been altered to show pressure, if I can just calculate the difference from where it is without the engine running to where it is with it running it maxes out at 20 psi and everyone knows a healthy engine is at least 40 psi. So I'm thinking it is mains and not rods or both. I can't swap engines where im at now and never should have got into this thing , but now I'm stuck with it and can't afford the loss.

#32

Seasoned Member

Thread Starter

well I finally got to it , the torque converter bolts were tight, then I drained the oil, and it looks like metallic paint. There are flakes all through it. Judging from the time I laid under it listening to it run I can almost bet it is in the third cylinder from front. or even all of them by now , but the most noise seems to be in the middle to the front. That could be an illusion though caused by the shape of the oil pan.

The oil drain plug was extremely tight, possibly because of the flakes settling into the threads? They are really fine flakes. I wonder if the flakes ruined the cam or lifters? How do you tell if an oil pump is good or not?

The oil drain plug was extremely tight, possibly because of the flakes settling into the threads? They are really fine flakes. I wonder if the flakes ruined the cam or lifters? How do you tell if an oil pump is good or not?

Last edited by munyanb; 06-17-2015 at 09:05 PM.

#33

Seasoned Member

Thread Starter

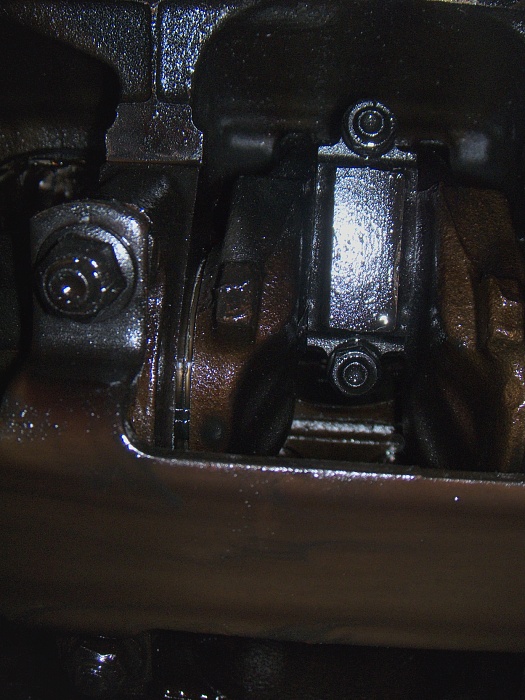

I took the pan off, and see flakes stuck to the block everywhere. Right away I find the rod bearing is so bad on the second cylinder from front that it is coming out the side. plenty of movement. All of the rod bearings move side to side but I can't really feel any up and down if there is some it is so slight its hard to really tell. So for checking the mains do I need to take them off? Hopefully I can get away with just replacing that one rod bearing without taking the whole thing apart. And about that oil pressure gauge, has anyone ran into that problem before? A bad rod bearing wouldn't lower oil pressure, so maybe the gauge does work somewhat. I couldn't move the crank but don't really have a good way to anyway. And when I say get away with replacing just that one, I mean doing that and it being dependable for another 100 k or so, it has 180k on it now I think.

#34

Seasoned Member

Thread Starter

#36

Old fart with a wrench

I'm going to tell you right now that after you get that rod cap off and look at the crank, it'll be scored enough to have to be reground before you can replace that bearing. In other words, it's rebuild time.

#37

Seasoned Member

Thread Starter

Oh yeah I know the one rod will be scored for sure, or rather the crank where it connects to that rod. I have to wonder what causes one rod to go bad. So anyway , I've been into engines before , but haven't really re done a bottom end. Should I go ahead and yank the entire crank? I guess I sorta have to in order to be able to regrind that one journal. journal is the correct term right?

#38

Old fart with a wrench

Yup, it's a journal. A long time ago, Sunnen made a grinder that fit on the crank and would allow you to grind a journal without taking the engine apart. There was a motor that drove the flywheel while the grinder went around. Kenny Thompson of Northeast Engines was the last guy in the Syracuse area to still do it, but he's dead over 20 years now. You'll have to pull the crank and take it to a shop to get it done now. You'll probably need a rod as well.

As a matter of fact, you will be better off rebuilding the whole motor if you're going to take it apart anyhow. You've got the separate the engine from the tranny in order to get the crank out.

As a matter of fact, you will be better off rebuilding the whole motor if you're going to take it apart anyhow. You've got the separate the engine from the tranny in order to get the crank out.

#39

Seasoned Member

Thread Starter

I have a local mechanic that swears I can do this in frame. I am not trying to disrespect anyone or say someone else is wrong , but I have to try this. The "theory" is that if you take a perfectly sized strip of sand paper , wrap it around the journal, then wrap a string around the journal and sand paper and pull it back and forth making sure to apply even pressure and make more than a complete turn to get it all even you can get it good enough. I have researched this online and people are doing this but not in frame. Even on the third generation Camaro site a veteran mechanic talks about this and says grooves are ok to be left, but the break in process has to be very easy going. No high rpm's or lugging in higher gear. I know it sounds shady, but I will try this and if it works will break it in then drive the vehicle myself for at least 1,000 miles to make sure it isn't going to blow up on someone when I sell it off. This local mechanic says he has done it several times with no problems, every case is different though. It could be that the rod is to far out of shape, I see people saying that .001 is the tolerance usually, which is really a tight tolerance to begin with. I would suspect that even factory new has that much, .001 is really nothing at all. I think it's a miss print and was meant to be .01 . Any thoughts on this ? If I do end up having to rebuild this thing, I can't spend all that money and leave it stock, it is against my religion lol. Any thoughts from anyone? Don't burn me on a cross please.

#40

Seasoned Member

Thread Starter

Oh and anyone doing this or any other bottom end work please wear gloves, there are sharp edges everywhere. I pay very close attention to detail and am very careful and used to working hot electricity and around dangerous power tools and equipment and I have painful cuts all over my hands from messing with this. someone just jumping into this could get hurt really bad and you only get one set of hands , the engine can be replaced , not your body parts.

#41

Seasoned Member

Thread Starter

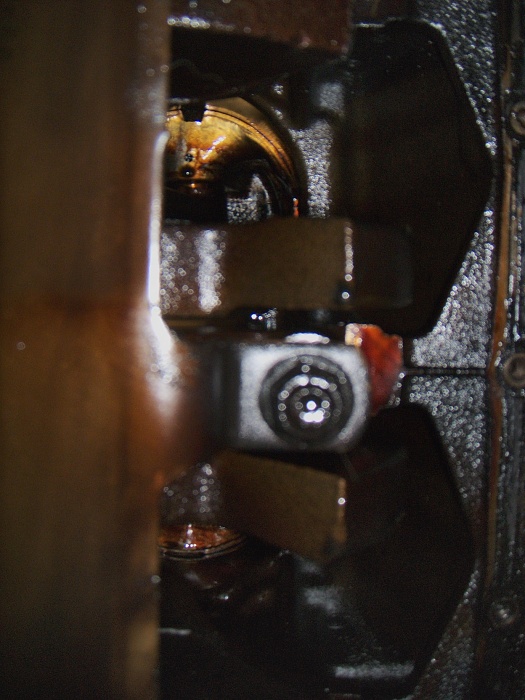

I did my in frame journal polishing , started with 180 grit 3m sand paper, worked it by hand for hours and used almost a sheet of sandpaper, cut in strips. Got it knocked down to where it was a little duller but uniform besides some minor grooves, then did the same with 400, but nearly as much or as long. Got it shining like chrome again besides the grooves. Took my micrometer , measured the shaft the best I could several times turned from one side to the other and measured, came up with most measurements between 2.087 and 2.083. This was very akward and hard to get to for the whole process, I guess I should have at least taken that lower brace off, or even a better location , like on a rack or blocked up higher, and not on a gravel slope. I think I have it pretty good and think my measurements were accurate so I ordred a set of .010 under rod bearings. So it's $6.00 for the bearings, about $3 for the sand paper, $1 and my old shoe strings and the cost of oil and a filter and some work, the better your work area the better this will go.

I did my in frame journal polishing , started with 180 grit 3m sand paper, worked it by hand for hours and used almost a sheet of sandpaper, cut in strips. Got it knocked down to where it was a little duller but uniform besides some minor grooves, then did the same with 400, but nearly as much or as long. Got it shining like chrome again besides the grooves. Took my micrometer , measured the shaft the best I could several times turned from one side to the other and measured, came up with most measurements between 2.087 and 2.083. This was very akward and hard to get to for the whole process, I guess I should have at least taken that lower brace off, or even a better location , like on a rack or blocked up higher, and not on a gravel slope. I think I have it pretty good and think my measurements were accurate so I ordred a set of .010 under rod bearings. So it's $6.00 for the bearings, about $3 for the sand paper, $1 and my old shoe strings and the cost of oil and a filter and some work, the better your work area the better this will go.

#42

Seasoned Member

Thread Starter

I have to wait till sunday to put it together but I think it's going to work, at least I hope. I was worried about it being out of round but I don't think it is. This could be done much easier also on a little home made rack or vice of some sort. Like I said earlier even taking that bottom brace off or the steering links or in a garage would have made this much easier and more precise, so I've got a 5.2 to look at next, lol

I have to wait till sunday to put it together but I think it's going to work, at least I hope. I was worried about it being out of round but I don't think it is. This could be done much easier also on a little home made rack or vice of some sort. Like I said earlier even taking that bottom brace off or the steering links or in a garage would have made this much easier and more precise, so I've got a 5.2 to look at next, lol

#43

Old fart with a wrench

Not to burst your bubble, but IDK this is going to work. I'll leave it at that.

#44

Seasoned Member

Thread Starter

I don't know if it will work either, but I am trying it. it would work for sure if I had a better work area, that's my only fear that the work area caused me to not get something uniform, like applying uniform pressure. I mic'd it and it seemed round. I do think if this engine blows it won't be this rod next time. At 188k you never know how much life is in it. I did notice some red die in the engine, not sure if the previous owner put diesel in it or it's the cleaner he put in, but I think he blew this engine when all that was wrong with it initially was bad spark plugs.

#45

Seasoned Member

Thread Starter

it's always better to go to a shop , but then you have to worry that the shop is truly doing good work. For people that don't have money to throw around and for an old engine that doesn't rev real high or make much power and has low compression I think this is a good chance. Like I said there is a mechanic in town here that says he has done several like this with a drill attachment to spin the sand paper. On youtube people are doing it, and even a third generation Camaro site working with partially built up engines are doing it.

I will let everyone know the outcome , but blame myself for poor workmanship if it fails , not the process.

I will let everyone know the outcome , but blame myself for poor workmanship if it fails , not the process.