nutsert pissin me off jcr tcase skid

#1

CF Veteran

Thread Starter

Join Date: Oct 2012

Location: Orlando/Winter Garden

Posts: 1,277

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: I6

#2

Junior Member

Join Date: Jun 2012

Location: Battle Creek, Michigan

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1992

Model: Cherokee

Engine: 4.0 HO

Just put a wrench on the nut and use a socket wrench on the end if the bolt and tighten. The nut is olny to put pressure on the nutsert, so when u tighten the nutsert will mushroom up. You should have a gear looking lock nut in between the nutsert and the washer so the nutsert won't spin on install

#3

CF Veteran

Thread Starter

Join Date: Oct 2012

Location: Orlando/Winter Garden

Posts: 1,277

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: I6

Yeah, the tool didnt come with a star washer. And in supposed to push insert all the way with hammer?

#4

::CF Administrator::

The engineer that came up with this style of fastener needs to be shot...absolutely hated these when I installed my sliders. Then I found out there is a tool that's supposed to make install easier, too late, though...can be had on ebay or amazon for around $40...or do what this guy did

http://www.wranglerforum.com/f19/cre...ze-202021.html

http://www.wranglerforum.com/f19/cre...ze-202021.html

#5

Junior Member

Join Date: Jun 2012

Location: Battle Creek, Michigan

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1992

Model: Cherokee

Engine: 4.0 HO

Trending Topics

#8

CF Veteran

Thread Starter

Join Date: Oct 2012

Location: Orlando/Winter Garden

Posts: 1,277

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: I6

Which means i want have to use the "tool" at all..my "tool" would be a hammer...? Sorry for all the questions, in just super worried/paranoid/careful when messing with my uniframe

#9

::CF Administrator::

No, the hole it inserts into is drilled slightly smaller than the nutsert, to help it stay snug when using the "tool" to set the nutsert....so, tap the nutsert in with the hammer, then use wrenches to tighten the "tool" portion, while the nutsert is in the hole. The outside of that nutsert is a crush sleeve, the portion of the sleeve with the lines will billow out when pressure is applied keeping it in the hole. It may help to have an extra set of hands when you do it.

#10

CF Veteran

Thread Starter

Join Date: Oct 2012

Location: Orlando/Winter Garden

Posts: 1,277

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: I6

Does it matter that the nut in between the two flat washer (yes, flat washer. Supposingly its supposed to be a star washer but jrc put 2 flat smooth washers) is bigger than the threaded bolt so that it moves freely? In basically in a way over tightening the bolt in the insert

#11

::CF Administrator::

The nut that's bigger is meant to be that way, so the threaded bolt spins freely, use one wrench to hold the big nut and another to tighten the threaded bolt into the nutsert, all while holding the oversized nut still with the other wrench. You need to keep the nutsert as straight as possible, without spinning in the hole, while you tighten the bolt, this will crush the sleeve against the hole. If the nutsert moves or spins, you can wallow out the hole, and good luck getting the nutsert set if that happens...have someone hold the wrench on the big nut straight while you tighten the threaded bolt, which will crush the sleeve into the hole. Don't go nuts when tightening, just enough to crush the sleeve in place, to hold it and keep it from spinning on final install. It may help to go grab some star washers that you can put between the nutsert and bottom washer to help keep it from spinning, at your local H/W store.

#12

CF Veteran

Join Date: Sep 2011

Location: new mexico

Posts: 1,874

Likes: 0

Received 1 Like

on

1 Post

Year: 88

Engine: 4.0

The engineer that came up with this style of fastener needs to be shot...absolutely hated these when I installed my sliders. Then I found out there is a tool that's supposed to make install easier, too late, though...can be had on ebay or amazon for around $40...or do what this guy did

http://www.wranglerforum.com/f19/cre...ze-202021.html

http://www.wranglerforum.com/f19/cre...ze-202021.html

#13

::CF Administrator::

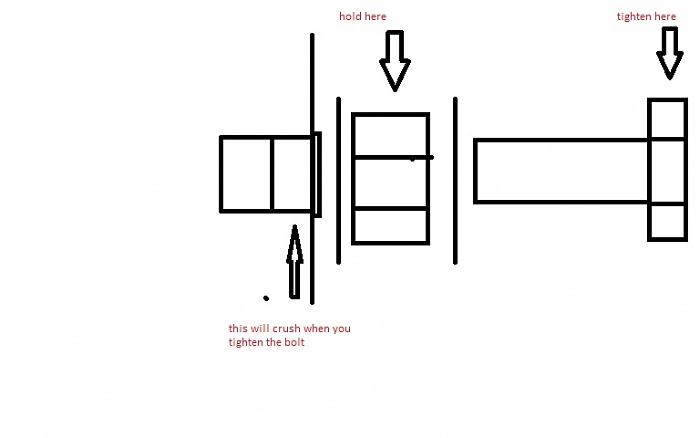

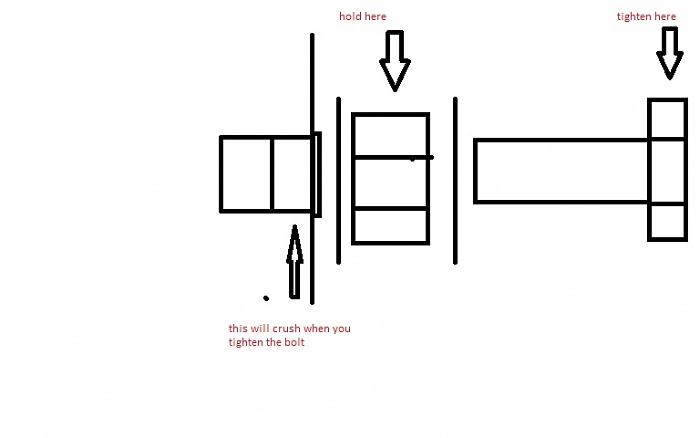

Yeah, I was in aerospace for 25+ years, and never used these things, I was on the space side and not the aero side, LOL...and as far as being a good idea, I agree, but if you don't have the proper tools, it makes it difficult...an engineer I worked with clued me in on the tool post install. I made a quick little diagram in paint to try to help...

so this shows the nutsert installed into the metal where you want it, followed by the washer, oversized nut, washer and bolt. Hope this helps...

so this shows the nutsert installed into the metal where you want it, followed by the washer, oversized nut, washer and bolt. Hope this helps...

#14

CF Veteran

Thread Starter

Join Date: Oct 2012

Location: Orlando/Winter Garden

Posts: 1,277

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: I6

The nut that's bigger is meant to be that way, so the threaded bolt spins freely, use one wrench to hold the big nut and another to tighten the threaded bolt into the nutsert, all while holding the oversized nut still with the other wrench. You need to keep the nutsert as straight as possible, without spinning in the hole, while you tighten the bolt, this will crush the sleeve against the hole. If the nutsert moves or spins, you can wallow out the hole, and good luck getting the nutsert set if that happens...have someone hold the wrench on the big nut straight while you tighten the threaded bolt, which will crush the sleeve into the hole. Don't go nuts when tightening, just enough to crush the sleeve in place, to hold it and keep it from spinning on final install. It may help to go grab some star washers that you can put between the nutsert and bottom washer to help keep it from spinning, at your local H/W store.

#15

::CF Administrator::

No worries, take one of your bolts with you and pick up a few star washers while you're there, and try it, it may help....