Gear wear pattern

#1

Junior Member

Thread Starter

Join Date: Jun 2014

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

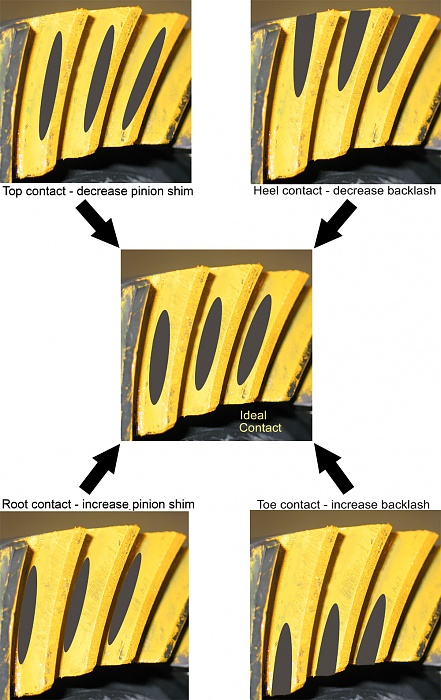

Model: Cherokee

So I have been working at regearing the jeep for several days now and this is about the 3rd time for setting up gears in my wrenching days. I am in question ans want to know what others think about my wear pattern. This is about the most desirable IMHO pattern I could get. Still not 100% happy with it but what's others opinions, with experience?

#2

::CF Administrator::

#3

Junior Member

Thread Starter

Join Date: Jun 2014

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

I snapped one coast side pic before leaving the shop and now can't find it on my phone. The coast looked good tho IMHO. It's just that drive side I couldn't get any better. This was as close to "sweet" as I felt I could get and this was under a load too with heavy brakes applied.

#4

::CF Administrator::

I snapped one coast side pic before leaving the shop and now can't find it on my phone. The coast looked good tho IMHO. It's just that drive side I couldn't get any better. This was as close to "sweet" as I felt I could get and this was under a load too with heavy brakes applied.

Zero issues. Working awesome. Hope this helped...

#5

Junior Member

Thread Starter

Join Date: Jun 2014

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

Hey bud thanks a lot! Of course it helped. Your coast is almost spitting image of mine and drive is very similar too, makes me feel better. I have never had any gears brought back yet, lol but I just always second guess myself. Now off to do the d30, wish me luck and I will post results here for anyone else interested and for more assurance so please check back soon.

#6

::CF Administrator::

Hey bud thanks a lot! Of course it helped. Your coast is almost spitting image of mine and drive is very similar too, makes me feel better. I have never had any gears brought back yet, lol but I just always second guess myself. Now off to do the d30, wish me luck and I will post results here for anyone else interested and for more assurance so please check back soon.

Trending Topics

#8

Senior Member

Join Date: Nov 2011

Location: Tallahassee, FL

Posts: 596

Likes: 0

Received 7 Likes

on

7 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

Do you press the bearings on and off each time? or do did you hone out a set of bearings to slip on and off for setup? (which I did the first time) then press on the new bearings at the end and check pattern one more time??? I did my TJ's Dana 30 and 44 about 4 years ago and they worked out great and I used "setup bearings", now I am getting ready to do my XJ Dana 30 (The 8.25 was already re-geared when I bought that axle).

#9

CF Veteran

Join Date: Apr 2011

Location: Carrollton, GA

Posts: 14,553

Likes: 0

Received 1 Like

on

1 Post

Year: 1994

Model: Cherokee

Engine: Inline 6 4.0L High Output

If the BL is good I would run it. Maybe try to get .001 tighter. What's the other side look like?

I dremeled the stock bearings out to slide on the carrier for set up bearings then added .003 to each side when pressing the new bearings on to add preload. 8.25 uses adjuster collars so you just press them on when you start.

I dremeled the stock bearings out to slide on the carrier for set up bearings then added .003 to each side when pressing the new bearings on to add preload. 8.25 uses adjuster collars so you just press them on when you start.

#10

Junior Member

Thread Starter

Join Date: Jun 2014

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

The coast side is a little less than ideal but I am too satisfied with drive side to go messing with it.

As for setup, absolutely go with setup or dummy bearings.

How do I make sure I have the correct thickness/amount of pinion preload shims? What is the step-by-step process for pinion preload setup?

As for setup, absolutely go with setup or dummy bearings.

How do I make sure I have the correct thickness/amount of pinion preload shims? What is the step-by-step process for pinion preload setup?

Last edited by Doug84; 01-19-2015 at 09:48 PM.

#11

Senior Member

Join Date: May 2014

Location: Colorado

Posts: 672

Likes: 0

Received 4 Likes

on

4 Posts

Year: 2001, 1997

Model: Cherokee

Engine: 4.0L

Pinion preload on the HP 30 is an iterative process until you get it where you want it. Start with the old shim stack and add a little. Better to have too many shims at first. Once you have an idea how far out you are, you can take away from the shim stack. Once you get close, a .001 shim is about 8 in-lb. Spec is 15-35 in-lb.

#12

Junior Member

Thread Starter

Join Date: Jun 2014

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

Will the bearings not tighten in their cups and give a false preload? I guess what I am asking is how will I know when the shims are doing their job different than just tightening down on the nut until I damage the bearings?

#13

CF Veteran

Join Date: Feb 2013

Location: Justin, TEXAS

Posts: 1,802

Likes: 0

Received 2 Likes

on

2 Posts

Year: 1988

Model: Cherokee

Engine: 4.0

Too less shims= way to much pinion bearing preload at torque spec.

Good a mount of shims= nut at torque spec and pinion pre load in spec

Gotta find that perfect balance man. Patterns looked good! I'd run them as long as the backlash was good

#14

Senior Member

Join Date: May 2014

Location: Colorado

Posts: 672

Likes: 0

Received 4 Likes

on

4 Posts

Year: 2001, 1997

Model: Cherokee

Engine: 4.0L

As you tighten the pinion nut down, stop every 1/4 turn or so and turn the pinion a few times to help seat the bearings. This is more important once you get towards the upper end on torque rather than throughout. Once you think you've got the right shim stack, I would loosen everything up and try torquing it down again to make sure it doesn't change on you.

#15

Junior Member

Thread Starter

Join Date: Jun 2014

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

Started with the factory preload shim stack and I have too much rotational resistance. I am at 45 inch pounds with no carrier in place. I didn't think it was possible to have too much preload. What should I be looking for? I need more shims?