Welding thread!!!!

#2269

::CF Administrator::

#2270

Seasoned Member

I need to do that as well.

Don't you have to heat up the cast material before you weld and then when you're done, cover it so it cools slowly?

Don't you have to heat up the cast material before you weld and then when you're done, cover it so it cools slowly?

#2271

CF Veteran

Join Date: Apr 2016

Location: Pasquotank, NC

Posts: 1,679

Likes: 0

Received 15 Likes

on

13 Posts

Year: 1990

Model: Cherokee

Engine: 4.0

That is the standard procedure for welding cast. I didn't do that welding up the low spots in the knuckle though. Next time I pull the front tire, I will see how it is holding up. It's been about a year or so. The brakes are functioning well, so it must be good right?

#2272

Seasoned Member

aww ok, I'm still learning. Most of the time I don't even know how to setup the welder for welding that.

For metal that thick, how do you know what settings you need?

For metal that thick, how do you know what settings you need?

#2273

No, I don't lick fish.

I already knew this, but someone sent me this link the other day, thought I'd post it up for those who don't know, he does a great job laying it out

https://youtu.be/mHBanmfn_CA

https://youtu.be/mHBanmfn_CA

The pads I'm using also came with steel shims to help them slide better and, I believe I may have use too thick of shims so they might not be sliding quite right. I'm still thinking my worn out control arm bushings might be contributing to a little bit of pulling as well though.

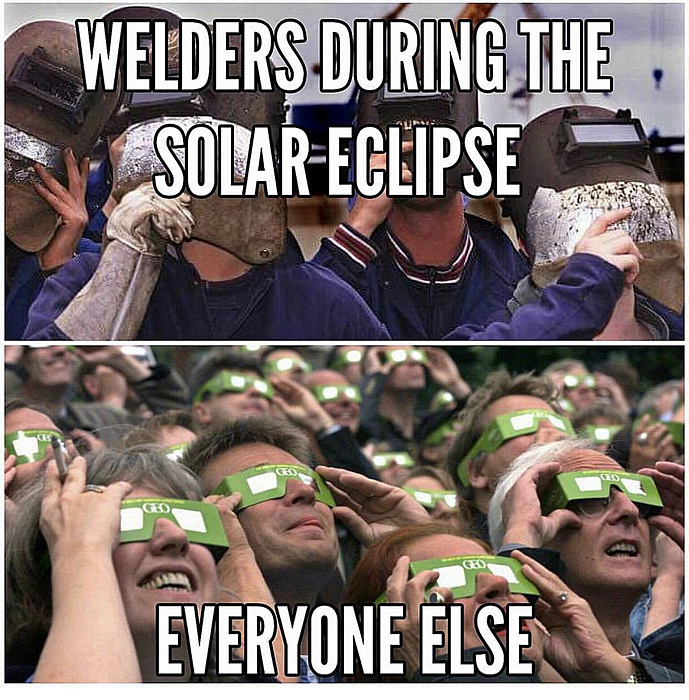

Me lol... I used my hood while I had a handheld shield for the kids to pass around and look through.

You seasoned welders correct me if I'm wrong, here.

Last edited by Basslicks; 08-23-2017 at 02:26 AM.

#2275

::CF Administrator::

#2276

CF Veteran

Join Date: May 2015

Location: Arizona

Posts: 4,481

Likes: 0

Received 16 Likes

on

12 Posts

Year: 97

Model: Cherokee

Engine: 4.0

Some vertical up on a tee joint with a z weave. Weld ****, lol

First pic is a cover pass, bottom one is root pass

Attachment 398671

Attachment 398672

First pic is a cover pass, bottom one is root pass

Attachment 398671

Attachment 398672

Man... I can't even get close to that pretty on a vertical weld. I get even worse on an overhead.

#2277

::CF Administrator::

I'm doing some overhead stuff now, but open root is killer. Tough to get it right, Had to lower my voltage, tweak the inductance, and detune the wire speed...add keeping the proper work and drag travel angles and travel speed, it's a *****, haha...open root is the bane of my existence, LMAO

The projects I've been working on cover lap, fillet, tee, and open root groove welds. So far, I've been doing boobies, but as we all know over head is a killer, But I know once my open root is polished, the rest is gravy, baby, haha...

#2278

::CF Administrator::

BTW all of this is being done on 3/16", moving to 3/8" next, but so far I've knocked out flat, horizontal, vertical down, vertical up, and now overhead, using several different weave patterns. Should have most of my certs done in about 6-8 weeks.

#2279

CF Veteran

Join Date: May 2015

Location: Arizona

Posts: 4,481

Likes: 0

Received 16 Likes

on

12 Posts

Year: 97

Model: Cherokee

Engine: 4.0

Wish I took pics of that, but the other side got the same treatment. LOL

I'm doing some overhead stuff now, but open root is killer. Tough to get it right, Had to lower my voltage, tweak the inductance, and detune the wire speed...add keeping the proper work and drag travel angles and travel speed, it's a *****, haha...open root is the bane of my existence, LMAO

The projects I've been working on cover lap, fillet, tee, and open root groove welds. So far, I've been doing boobies, but as we all know over head is a killer, But I know once my open root is polished, the rest is gravy, baby, haha...

I'm doing some overhead stuff now, but open root is killer. Tough to get it right, Had to lower my voltage, tweak the inductance, and detune the wire speed...add keeping the proper work and drag travel angles and travel speed, it's a *****, haha...open root is the bane of my existence, LMAO

The projects I've been working on cover lap, fillet, tee, and open root groove welds. So far, I've been doing boobies, but as we all know over head is a killer, But I know once my open root is polished, the rest is gravy, baby, haha...

#2280

::CF Administrator::

Yes. Two plates butted together with a gap in the center. Tack together, then fill the void. Creates what's called a keyhole, and it's just like it sounds, looks like an old school keyhole, the trick is to keep everything in line to keep the keyhole open, as you travel along the open root. Follow the puddle, stay on the leading edge. If you learn how to read the puddle, it just clicks, it is counter intuitive, sometimes, depending on the process used, like with SMAW, you need to feed AHEAD of the puddle, and it back fills as you travel. Harder to control, MIG is much more forgiving, haha