Welding thread!!!!

#17

::CF Administrator::

LOL....7018 = tons of slag....not a big deal unless you're welding overhead, LMAO....good looking stick welds, though

#18

CF Veteran

Join Date: Mar 2011

Location: Waterloo, Iowa

Posts: 1,102

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2000

Model: Cherokee

Engine: 4.0

#20

Junior Member

It's pretty common knowledge that my welds generally always look like **** and require lots of 36 grit flap discs. lol

I blame that on my fidgety hands and flux core wire.

Hobart Handler 140, .30 Flux core. (Small shop and usually have to weld outside with no cart so I'm not lugging a tank everywhere.)

and just because I happen to have a picture of it...

I blame that on my fidgety hands and flux core wire.

Hobart Handler 140, .30 Flux core. (Small shop and usually have to weld outside with no cart so I'm not lugging a tank everywhere.)

and just because I happen to have a picture of it...

#21

Lowrange, I work a fab shop with some AMAZING welders. I have been welding for LONG time and I can tell you to make GREAT looking welds takes a lot of time. Yours look really good. I would be proud of those welds. One thing I have learned is cutting your weld in half to see how bad it is contaminated. When I started working there I thought I was a decent welder but one of the old welders took one of my welds and cut it in half and WOW that was an eye opener.

#22

CF Veteran

Guess I'll post up what I've done with my little Lincoln SP125 Plus (older little MIG welder.) Used flux core for most everything except the floor pans. Done everything from 18 gauge floor pans to 1/4" bumpers.

Last edited by Dan91; 01-04-2014 at 10:53 AM.

#23

CF Veteran

Join Date: Apr 2012

Location: Ross Vegas, Ga

Posts: 1,843

Likes: 0

Received 2 Likes

on

2 Posts

Year: 2000

Model: Cherokee

Engine: 4.0 w/ tupy head

Thats what i got but just have to find the time to get out there and practise...its hard with a wife and two kids..plus 19 degree weather here in ga..cool thread ..mabee it will motivate me to get out there and burn.

#24

CF Veteran

Join Date: Apr 2012

Location: Ross Vegas, Ga

Posts: 1,843

Likes: 0

Received 2 Likes

on

2 Posts

Year: 2000

Model: Cherokee

Engine: 4.0 w/ tupy head

It's pretty common knowledge that my welds generally always look like **** and require lots of 36 grit flap discs. lol

I blame that on my fidgety hands and flux core wire.

Hobart Handler 140, .30 Flux core. (Small shop and usually have to weld outside with no cart so I'm not lugging a tank everywhere.)

and just because I happen to have a picture of it...

I blame that on my fidgety hands and flux core wire.

Hobart Handler 140, .30 Flux core. (Small shop and usually have to weld outside with no cart so I'm not lugging a tank everywhere.)

and just because I happen to have a picture of it...

#26

CF Veteran

Join Date: Mar 2011

Location: Waterloo, Iowa

Posts: 1,102

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2000

Model: Cherokee

Engine: 4.0

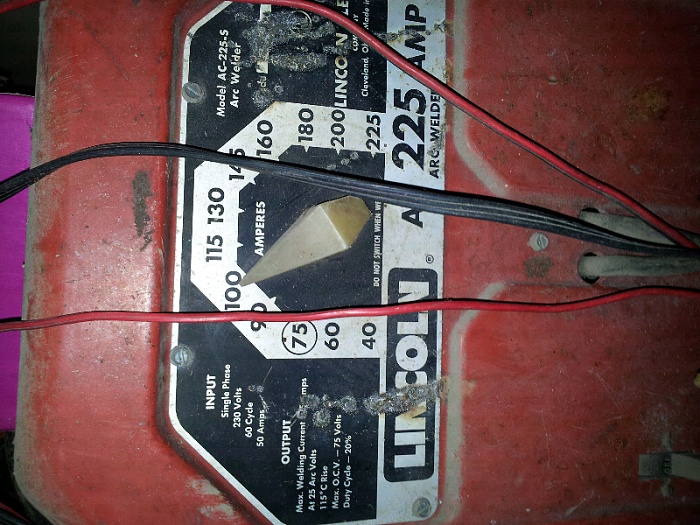

Cool im glad alot of you guys are using this mig.ill be using flux core also..heres mine

Attachment 225852

Attachment 225852

#28

CF Veteran

Join Date: Sep 2012

Location: Springfield Virginia

Posts: 1,289

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

Go on amazon they've got a reconditioned 140 that's usually about $200 cheaper than new. It's usually out of stock but pops up now and again. I'll be buying it pretty soon

Last edited by ThatPurpleXJ; 01-04-2014 at 12:04 PM.

#30

CF Veteran

Join Date: Apr 2012

Location: Ross Vegas, Ga

Posts: 1,843

Likes: 0

Received 2 Likes

on

2 Posts

Year: 2000

Model: Cherokee

Engine: 4.0 w/ tupy head

I need to start my front..i kinda dont like the tire carriers..i get in the back of the jeep over ten times a day..it seems like it would be in the way plus I don't have a matching spare. that reminds me I gotta get new struts for the hatch.lol