Advice on TTY head bolts

#1

Newbie

Thread Starter

Join Date: May 2015

Location: Central Florida

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1987

Model: Cherokee

Engine: 4.0

Hello all, time for a doozie of a first post.

I have an 87 XJ 4.0 that I had to take the head off of (long story) I'm putting it back on and have run into a snag. I bought the TTY head bolts for a 96+ as the existing were in unknown condition at the time and for $30 it seemed like good insurance. Last night I was torquing them down and when I got to #2 on the final torque sequence the bolt threads started to strip as soon as I hit 100ft/lbs.

I stopped at this point because I noticed the 1/2" deep well 1/2 12pt socket was bottoming out on the top of these new bolts so it couldn't seat all the way on the threads of the longer head bolts. I'm going to pick up a 3/8 version of the same socket tonight but I'm not reusing that bolt.

Would you replace it with the best looking original bolt or should I bite the bullet and pick up a new set to replace the bolt?

I'm assuming I need to loosen all the bolts back and start over on the torque sequence to seat the gasket again, is this correct? (guess that means I need two bolts then??)

At what point do the TTY become unusable? Do they stretch at a certain torque rating or only after it's been run etc?

Any suggestions on tightening the #14 bolt down? I have a 3/8 torque wrench that only goes to 80ft/lbs, 1/2 torque wrench wont fit back there. Is renting/buying a 3/8 that goes up to 100 my only option here or am I overlooking something obvious?

I really don't want to have to do this whole thing again in a couple months due to something preventable now as this was an expensive PITA.

Thanks

I have an 87 XJ 4.0 that I had to take the head off of (long story) I'm putting it back on and have run into a snag. I bought the TTY head bolts for a 96+ as the existing were in unknown condition at the time and for $30 it seemed like good insurance. Last night I was torquing them down and when I got to #2 on the final torque sequence the bolt threads started to strip as soon as I hit 100ft/lbs.

I stopped at this point because I noticed the 1/2" deep well 1/2 12pt socket was bottoming out on the top of these new bolts so it couldn't seat all the way on the threads of the longer head bolts. I'm going to pick up a 3/8 version of the same socket tonight but I'm not reusing that bolt.

Would you replace it with the best looking original bolt or should I bite the bullet and pick up a new set to replace the bolt?

I'm assuming I need to loosen all the bolts back and start over on the torque sequence to seat the gasket again, is this correct? (guess that means I need two bolts then??)

At what point do the TTY become unusable? Do they stretch at a certain torque rating or only after it's been run etc?

Any suggestions on tightening the #14 bolt down? I have a 3/8 torque wrench that only goes to 80ft/lbs, 1/2 torque wrench wont fit back there. Is renting/buying a 3/8 that goes up to 100 my only option here or am I overlooking something obvious?

I really don't want to have to do this whole thing again in a couple months due to something preventable now as this was an expensive PITA.

Thanks

#2

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Hello all, time for a doozie of a first post.

I have an 87 XJ 4.0 that I had to take the head off of (long story) I'm putting it back on and have run into a snag. I bought the TTY head bolts for a 96+ as the existing were in unknown condition at the time and for $30 it seemed like good insurance. Last night I was torquing them down and when I got to #2 on the final torque sequence the bolt threads started to strip as soon as I hit 100ft/lbs.

I stopped at this point because I noticed the 1/2" deep well 1/2 12pt socket was bottoming out on the top of these new bolts so it couldn't seat all the way on the threads of the longer head bolts. I'm going to pick up a 3/8 version of the same socket tonight but I'm not reusing that bolt.

Would you replace it with the best looking original bolt or should I bite the bullet and pick up a new set to replace the bolt?

I'm assuming I need to loosen all the bolts back and start over on the torque sequence to seat the gasket again, is this correct? (guess that means I need two bolts then??)

At what point do the TTY become unusable? Do they stretch at a certain torque rating or only after it's been run etc?

Any suggestions on tightening the #14 bolt down? I have a 3/8 torque wrench that only goes to 80ft/lbs, 1/2 torque wrench wont fit back there. Is renting/buying a 3/8 that goes up to 100 my only option here or am I overlooking something obvious?

I really don't want to have to do this whole thing again in a couple months due to something preventable now as this was an expensive PITA.

Thanks

I have an 87 XJ 4.0 that I had to take the head off of (long story) I'm putting it back on and have run into a snag. I bought the TTY head bolts for a 96+ as the existing were in unknown condition at the time and for $30 it seemed like good insurance. Last night I was torquing them down and when I got to #2 on the final torque sequence the bolt threads started to strip as soon as I hit 100ft/lbs.

I stopped at this point because I noticed the 1/2" deep well 1/2 12pt socket was bottoming out on the top of these new bolts so it couldn't seat all the way on the threads of the longer head bolts. I'm going to pick up a 3/8 version of the same socket tonight but I'm not reusing that bolt.

Would you replace it with the best looking original bolt or should I bite the bullet and pick up a new set to replace the bolt?

I'm assuming I need to loosen all the bolts back and start over on the torque sequence to seat the gasket again, is this correct? (guess that means I need two bolts then??)

At what point do the TTY become unusable? Do they stretch at a certain torque rating or only after it's been run etc?

Any suggestions on tightening the #14 bolt down? I have a 3/8 torque wrench that only goes to 80ft/lbs, 1/2 torque wrench wont fit back there. Is renting/buying a 3/8 that goes up to 100 my only option here or am I overlooking something obvious?

I really don't want to have to do this whole thing again in a couple months due to something preventable now as this was an expensive PITA.

Thanks

What's with using Torque To Yield bolts? Get a new set of Felpro bolts from your local parts store and use them.

I use a 1/2" drive, 1/2" 12 point deep socket from Lowes. I had to drill out the top inner portion of the socket so the bolt threaded portion would pass through. No biggy.

As for #14 bolt, cut the threaded portion of that bolt off so you can get a shallow socket on it. Pic below.

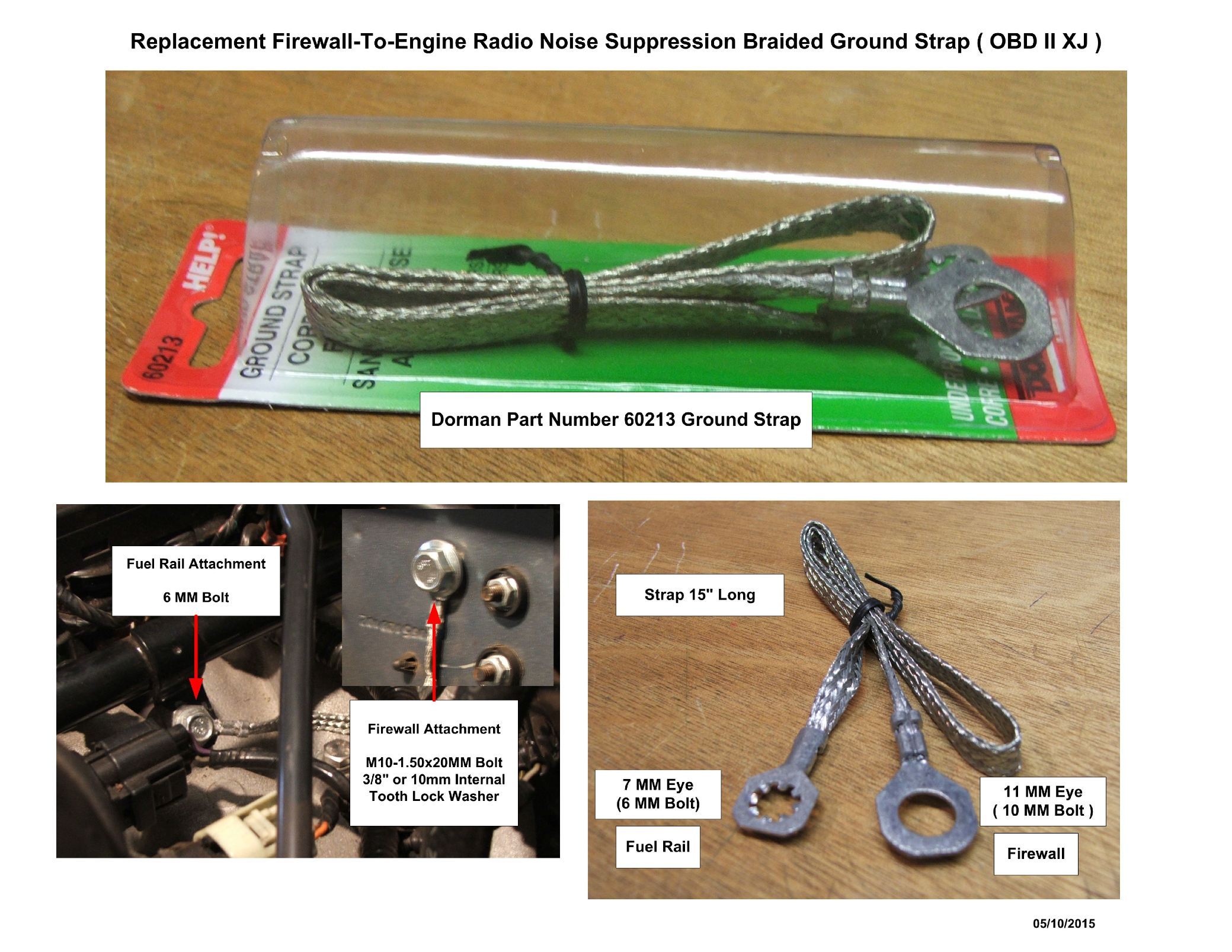

As for the braided bonding strap that went to that bolt, toss it and get a new strap to attach to a fuel rail hold down bolt. Strap available from O'reilly Auto Parts. Pic below

Modified bolt:

Replacement bonding strap:

#3

Newbie

Thread Starter

Join Date: May 2015

Location: Central Florida

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1987

Model: Cherokee

Engine: 4.0

Hmmm those are the ones I have ES-71102, I was under the impression that they were TTY bolts, ES series from Fel-pro

http://fme-cat.com/livedocs/Head%20Bolt%20Sets.pdf

http://fme-cat.com/livedocs/Head%20Bolt%20Sets.pdf

#5

Newbie

Thread Starter

Join Date: May 2015

Location: Central Florida

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1987

Model: Cherokee

Engine: 4.0

Thanks, in the interest of getting this done I used a hammer to "notch" the lip above the #14 bolt, remove it, cut the top threads down and retorqued it all following the proper sequence. Hopefully it will hold up. Some of the bolts may be over torqued by 5-7ft-lbs due to the slop in the wrench but we'll see.

For those that may do this in the future and go down this path cut the bolt top first, then put the head in and you won't have to "modify" the lip above it. I ended up using a 3/8 deep 12pt 1/3 socket to do the other taller bolts. For #14 and the shorter bolts I used a 1/2 12pt 1/2 socket.

Thread

Thread Starter

Forum

Replies

Last Post

jurazov

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

12

07-20-2023 04:13 AM

NM-XJ

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

18

10-23-2018 04:21 PM

Silentj

Stock XJ Cherokee Tech. All XJ Non-modified/stock questions go here

7

09-06-2015 08:46 PM

Currently Active Users Viewing This Thread: 1 (0 members and 1 guests)