Multiple codes and engine bucking... what to do

#1

Junior Member

Thread Starter

Join Date: Oct 2012

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

I have Codes P0107, P0700, P0705, P1296. The jeep bucks while accelerating and sometime dies at stop signs. I can accelerate hard and the bucking stops. This year i have replaced the O2 sensors both. The Cat Converter and exhaust is new. I have checked the wiring harness and its all zipped tied up so it hasnt been cut into. Please help i dont want to start throwing parts at it. I also dont wanna take it to a shop no telling how much they would charge and probably not get it right.

Thanks in advance!

Thanks in advance!

#2

CF Veteran

Join Date: Nov 2010

Location: In the middle of Minnesota!

Posts: 5,805

Received 99 Likes

on

88 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

I always start with chasing the lowest number code. And that for you is P0107 which is a MAP sensor code. I would test or replace it. It is a very important sensor that is directly involved with fuel/air ratio. If you replace it, then clear codes and see what comes back.

Here is more on that code.

http://www.obd-codes.com/p0107

Here is more on that code.

http://www.obd-codes.com/p0107

#3

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

P1296 is an Enhanced Code (Chrysler assigned). Also MAP.

No 5 volts to Map Sensor - Loss of a 5 volt feed to the MAP Sensor has been detected.

As tjwalker said, you should test the MAP Sensor, specifically for a 5 volt reference voltage at the MAP Sensor connector, pin 3, Orange wire, key in RUN (ON) position.

No 5 volts to Map Sensor - Loss of a 5 volt feed to the MAP Sensor has been detected.

As tjwalker said, you should test the MAP Sensor, specifically for a 5 volt reference voltage at the MAP Sensor connector, pin 3, Orange wire, key in RUN (ON) position.

#5

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

P0700 is a generic code that basically says there's a fault in the Transmission Control Module (TCM) - which is P0705, Range Sensor (aka NSS) fault.

Wiggle your wiring harnesses in the engine bay and look for chafed wiring.

Wiggle your wiring harnesses in the engine bay and look for chafed wiring.

#6

Junior Member

Thread Starter

Join Date: Oct 2012

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

It is a 96 Jeep Cherokee. It doesnt have any chaffed wires. I have a friend bringing over a multimeter to check the MAP sensor will let you know! Thanks!

Trending Topics

#8

CF Veteran

Join Date: Nov 2010

Location: In the middle of Minnesota!

Posts: 5,805

Received 99 Likes

on

88 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

But you do have 5.1 so that is proper input voltage. So that is all you know at this point.

#9

Junior Member

Thread Starter

Join Date: Oct 2012

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

http://www.cherokeetalk.com/forum/f6...rocedure-1261/

Ran this test.

Got 5.1 on C with key in on spot.

4.3 on B with key in ON

2.1 at B at idle

So it looks like the sensor is running right so now i am in limbo again

Ran this test.

Got 5.1 on C with key in on spot.

4.3 on B with key in ON

2.1 at B at idle

So it looks like the sensor is running right so now i am in limbo again

#10

Junior Member

Thread Starter

Join Date: Oct 2012

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

I tested the TPS since it had high output code. It was reading 9.8 V which is crazy high. WHat should i do replace it? It reads 9.8 whith the harness unplugged to so how do i get the voltage down?

#11

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Do you have Cruise Control?

Do you have Air Bags?

~~~~~~~~~~~

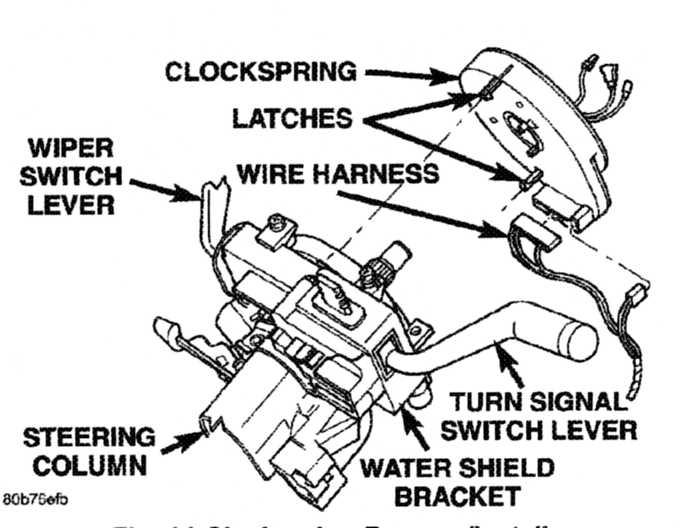

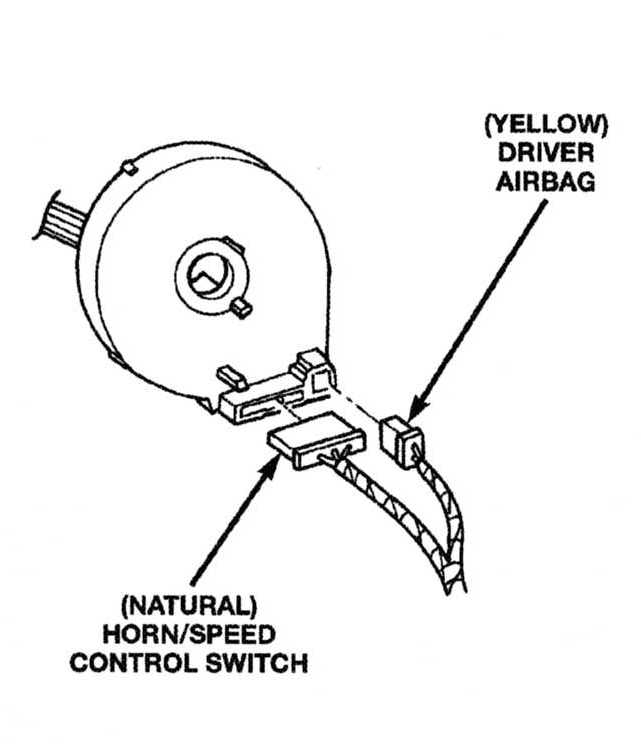

On XJ's that have Air Bags (Clockspring) and have Cruise Control (or built in factory CC wiring, there have been cases where a defective clockspring allows power from the Horn relay control circuit to bleed through to the cruise control circuit and then to the sensors 5 volt reference voltage output from the PCM.

To determine if this is the case, you can isolate the clockspring from the CC circuit by disconnecting the CC connector from the clockspring, and see if the high voltage at the TPS drops to its normal 5 volts. If this is the case the clockspring needs to be replaced.

Here's how to isolate the CC from the clockspring:

1. Remove the negative (-) battery post connector. Allow the Jeep to sit for 30 minutes before proceeding,

Caution: Whenever you disconnect or reconnect the electrical connectors on the clockspring make sure you disconnect the battery negative cable and allow the vehicle sit for at least 30 minutes to allow the airbag condensor to dissipate.

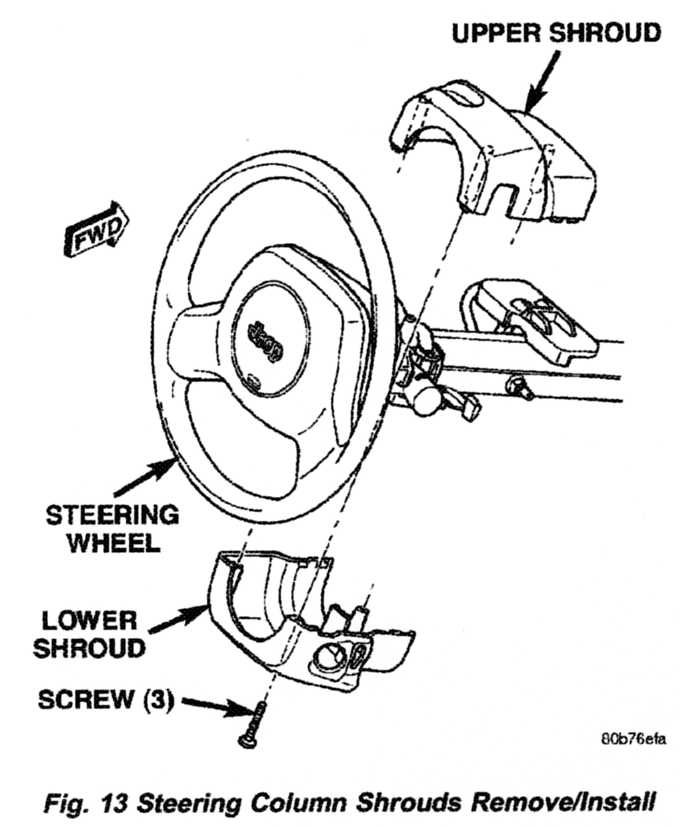

2. Remove the upper and lower shrouds from the steering column,

3. Detach the Horn/Speed Control connector from the Clockspring,

4. Reconnect the (-) battery connector,

5. Check for 5 volts at the sensor. If the voltage is 5 volts replace the clockspring. If the voltage is still high there is a short to another power source.

#12

Junior Member

Thread Starter

Join Date: Oct 2012

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Model: Cherokee

Ok well i went outside last night and i unplugged my what i originally thought was TPS but it turned out to be my IACV and i took it for a drive it drove absolutely perfect! So would that mean that its just a bad IACV throwing all these codes? I redid the test on the actual TPS and it is 5V.

#14

CF Veteran

Join Date: Nov 2010

Location: In the middle of Minnesota!

Posts: 5,805

Received 99 Likes

on

88 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

Below is information on the 91-01 throttle position sensor, including how to properly test it.

---------------------------------------------------------

The throttle position sensor is connected to the throttle shaft on the throttle body. It sends throttle valve angle information to the PCM. The PCM uses this information to determine how much fuel the engine needs. The TPS is really just a simple potentiometer with one end connected to 5 volts from the PCM and the other to ground. A third wire is connected to the PCM. As you move the accelerator pedal with your foot, the output of the TPS changes. At a closed throttle position, the output of the TPS is low, about a half a volt. As the throttle valve opens, the output increases so that, at wide open throttle, the output voltage should be above 3.9 volts. Testing can be performed with an electrical meter. Analog meter is best. You are looking for a smooth sweep of voltage throughout the entire throttle band. While slowly opening and closing the throttle, take note to the movement of the voltmeter needle. There should be a direct relationship between the needle motion to the motion of the throttle. If at anytime the needle moves abruptly or inconsistently with the movement of the throttle, the TPS is bad

You should have 5 volts going into the TPS. At idle, TPS output voltage must be greater than 200 millivolts. At wide open throttle (WOT), TPS output voltage must be less than 4.8 volts.. The best is to use an analog meter (not digital) to see if the transition from idle to WOT is smooth with no dead spots. With your meter set for volts, put the black probe on a good ground like your negative battery terminal. With the key on, engine not running, test with the red probe of your meter (install a paper clip into the back of the plug of the TPS) to see which wire has the 5 volts. One of the other wires should show .26V (or so). The other wire will be the ground and should show no voltage. Move the throttle and look for smooth meter response up to the 4.49 at WOT.

Perform the test procedure again and wiggle and/or tap on the TPS while you watch the meter. If you notice any flat spots or abrupt changes in the meter readings, replace the TPS.

The TPS is sensitive to heat, moisture and vibration leading to the failure of some units. The sensor is a sealed unit and cannot be repaired only replaced. A TPS may fail gradually leading to a number of symptoms which can include one or more of the following: -

NOTE: The throttle position sensor is also DIRECTLY involved with transmission shifting characteristics! It should be verified early in the troubleshooting process, when a transmission issue is suspected!

• Poor idle control: The TPS is used by the ECU to determine if the throttle is closed and the car should be using the Idle Air Control Valve exclusively for idle control. A fault TPS sensor can confuse the ECU causing the idle to be erratic or "hunting".

• High Idle Speed: The TPS may report faulty values causing the engine idle speed to be increased above normal. This is normally found in conjunction with a slow engine return to idle speed symptom.

• Slow engine return to idle: A failing TPS can report the minimum throttle position values incorrectly which can stop the engine entering idle mode when the throttle is closed. Normally when the throttle is closed the engine fuel injectors will be deactivated until a defined engine RPM speed is reached and the engine brought smoothly to idle speed. When failing a TPS will not report the throttle closed and fueling will continue causing the engine to return to idle very slowly.

• Engine Hesitation on Throttle Application: The TPS is also used by the ECU to determine if the driver has applied the throttle quicker than the Manifold Air Pressure sensor can read. The fueling is adjusted accordingly to cope with the sudden increase in air volume, however a faulty sensor can cause the ECU to ignore this data and the engine will "hesitate" when applying the throttle. In extreme cases with the engine at idle, a sudden application of full throttle can stall the engine.

• Engine Misfire: A fault TPS can report values outside the denied acceptable range causing the ECU to incorrectly fuel the engine. This is noticeable as a slight misfire and can trigger the misfire detection software and/or Malfunction Indicator Lamp (MIL) light on the dashboard. Extreme cases can cause excessing misfires resulting in one or more cylinders being shut down to prevent engine and catalytic converter damage.

---------------------------------------------------------

The throttle position sensor is connected to the throttle shaft on the throttle body. It sends throttle valve angle information to the PCM. The PCM uses this information to determine how much fuel the engine needs. The TPS is really just a simple potentiometer with one end connected to 5 volts from the PCM and the other to ground. A third wire is connected to the PCM. As you move the accelerator pedal with your foot, the output of the TPS changes. At a closed throttle position, the output of the TPS is low, about a half a volt. As the throttle valve opens, the output increases so that, at wide open throttle, the output voltage should be above 3.9 volts. Testing can be performed with an electrical meter. Analog meter is best. You are looking for a smooth sweep of voltage throughout the entire throttle band. While slowly opening and closing the throttle, take note to the movement of the voltmeter needle. There should be a direct relationship between the needle motion to the motion of the throttle. If at anytime the needle moves abruptly or inconsistently with the movement of the throttle, the TPS is bad

You should have 5 volts going into the TPS. At idle, TPS output voltage must be greater than 200 millivolts. At wide open throttle (WOT), TPS output voltage must be less than 4.8 volts.. The best is to use an analog meter (not digital) to see if the transition from idle to WOT is smooth with no dead spots. With your meter set for volts, put the black probe on a good ground like your negative battery terminal. With the key on, engine not running, test with the red probe of your meter (install a paper clip into the back of the plug of the TPS) to see which wire has the 5 volts. One of the other wires should show .26V (or so). The other wire will be the ground and should show no voltage. Move the throttle and look for smooth meter response up to the 4.49 at WOT.

Perform the test procedure again and wiggle and/or tap on the TPS while you watch the meter. If you notice any flat spots or abrupt changes in the meter readings, replace the TPS.

The TPS is sensitive to heat, moisture and vibration leading to the failure of some units. The sensor is a sealed unit and cannot be repaired only replaced. A TPS may fail gradually leading to a number of symptoms which can include one or more of the following: -

NOTE: The throttle position sensor is also DIRECTLY involved with transmission shifting characteristics! It should be verified early in the troubleshooting process, when a transmission issue is suspected!

• Poor idle control: The TPS is used by the ECU to determine if the throttle is closed and the car should be using the Idle Air Control Valve exclusively for idle control. A fault TPS sensor can confuse the ECU causing the idle to be erratic or "hunting".

• High Idle Speed: The TPS may report faulty values causing the engine idle speed to be increased above normal. This is normally found in conjunction with a slow engine return to idle speed symptom.

• Slow engine return to idle: A failing TPS can report the minimum throttle position values incorrectly which can stop the engine entering idle mode when the throttle is closed. Normally when the throttle is closed the engine fuel injectors will be deactivated until a defined engine RPM speed is reached and the engine brought smoothly to idle speed. When failing a TPS will not report the throttle closed and fueling will continue causing the engine to return to idle very slowly.

• Engine Hesitation on Throttle Application: The TPS is also used by the ECU to determine if the driver has applied the throttle quicker than the Manifold Air Pressure sensor can read. The fueling is adjusted accordingly to cope with the sudden increase in air volume, however a faulty sensor can cause the ECU to ignore this data and the engine will "hesitate" when applying the throttle. In extreme cases with the engine at idle, a sudden application of full throttle can stall the engine.

• Engine Misfire: A fault TPS can report values outside the denied acceptable range causing the ECU to incorrectly fuel the engine. This is noticeable as a slight misfire and can trigger the misfire detection software and/or Malfunction Indicator Lamp (MIL) light on the dashboard. Extreme cases can cause excessing misfires resulting in one or more cylinders being shut down to prevent engine and catalytic converter damage.

#15

Member

Join Date: Jul 2011

Location: Greensburg, Pennsylvania

Posts: 151

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

Im having the same issue, the jeep runs normal when you restart it when this occurs. I took it to advance and code read it and got P0138 which means: Oxygen Sensor Short to Voltage Bank 1

Sensor 2

So I got a new magnaflow cat (old one was bad) and a new downstream o2 sensor. Still have to put them in but I have a feeling thats not what is causing this issue. I read to check my voltage to my MAP Sensor and to check my TPS and IAC. Can anyone tell me how to check these?

Sensor 2

So I got a new magnaflow cat (old one was bad) and a new downstream o2 sensor. Still have to put them in but I have a feeling thats not what is causing this issue. I read to check my voltage to my MAP Sensor and to check my TPS and IAC. Can anyone tell me how to check these?