Engine Ground

#1

Junior Member

Thread Starter

Join Date: Oct 2014

Posts: 53

Likes: 0

Received 3 Likes

on

3 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

So about 5 months ago I did an engine swap on my 99' (blew a head gasket and replaced it with another 4.0 out of a 99') and never put that engine ground strap that goes from the back of the block to the firewall back on (no idea where that thing even went) so ever since I've had this new engine in, sometimes it takes it 2-3 times for it to crank (which I just figured it was an ignition problem and I've just dealt with it because it hadn't really bothered me) and also maybe 1 out of every 10 starts it has a bad misfire and runs rough. Could this be from that engine ground?

The following users liked this post:

RoughXJstuff (02-17-2023)

#2

Member

Join Date: Jul 2015

Location: Sugar Land, TEXAS

Posts: 232

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2001

Model: Cherokee

Engine: 4.0 165,00 Miles

Any info on potential problems I keep. Had this one from another forum that might get you started. Good luck

Re: Ground strap on head to firewall

Yeah, that one's important, especially during cranking, when a ton of current is being drawn by the starter, grounded through the block, that strap, and a few other wires. If you have crummy grounds it can throw off various sensor readings due to the voltage difference between the chassis and the block.

I have had jeeps run decently without it, but grounding is marginal in XJs even without removing some. For reliability I would put it back on, or preferably replace it with heavy gauge welding cable. It's routed to the rear most head stud on the driver side from the factory but if you want to put it back on another one that's more accessible there is no reason not to, just clean the rust off first.

Re: Ground strap on head to firewall

Yeah, that one's important, especially during cranking, when a ton of current is being drawn by the starter, grounded through the block, that strap, and a few other wires. If you have crummy grounds it can throw off various sensor readings due to the voltage difference between the chassis and the block.

I have had jeeps run decently without it, but grounding is marginal in XJs even without removing some. For reliability I would put it back on, or preferably replace it with heavy gauge welding cable. It's routed to the rear most head stud on the driver side from the factory but if you want to put it back on another one that's more accessible there is no reason not to, just clean the rust off first.

#3

Senior Member

Join Date: Jul 2011

Location: West Covina, Ca.

Posts: 535

Likes: 0

Received 25 Likes

on

21 Posts

Year: 1988

Model: Cherokee

Engine: 4.0

Note from DJ

If you can’t find one NAPA has this cable that other Jeepers have used as a replacement.

P# 781116

Battery Cable End Type: Lug

Battery Cable Gauge(s): 4 Gage

Battery Cable Length: 18"

Color: Black

If you can’t find one NAPA has this cable that other Jeepers have used as a replacement.

P# 781116

Battery Cable End Type: Lug

Battery Cable Gauge(s): 4 Gage

Battery Cable Length: 18"

Color: Black

#5

CF Veteran

Join Date: Aug 2010

Location: Canton, MI

Posts: 8,357

Likes: 0

Received 82 Likes

on

67 Posts

Year: 1999

Model: Cherokee

Engine: 4.0

So about 5 months ago I did an engine swap on my 99' (blew a head gasket and replaced it with another 4.0 out of a 99') and never put that engine ground strap that goes from the back of the block to the firewall back on (no idea where that thing even went) so ever since I've had this new engine in, sometimes it takes it 2-3 times for it to crank (which I just figured it was an ignition problem and I've just dealt with it because it hadn't really bothered me) and also maybe 1 out of every 10 starts it has a bad misfire and runs rough. Could this be from that engine ground?

Can I assume that when you say "crank" you mean start as opposed to turning the engine over with the starter motor.

There are a number of things that can cause an engine to intermittently not start, or run rough and misfire, but I don't think that the bonding strap from the firewall to #14 cylinder head bolt would be one of the causes.

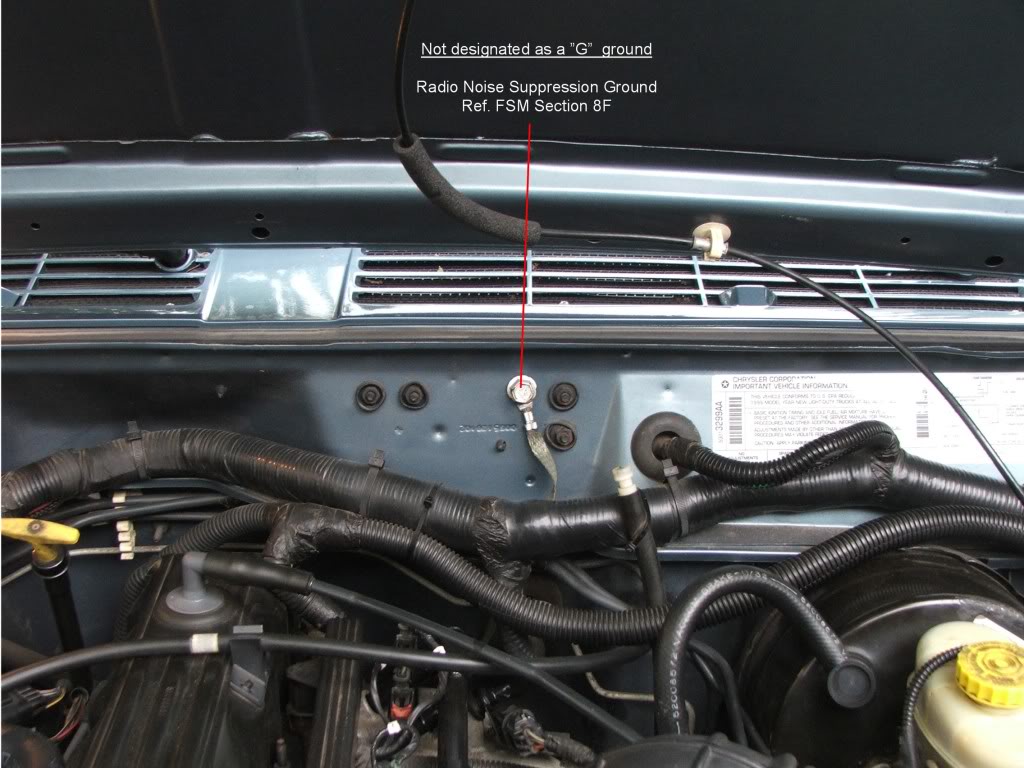

That bonding strap is for Radio Noise Suppression and was never intended to be a primary ground (see pic).

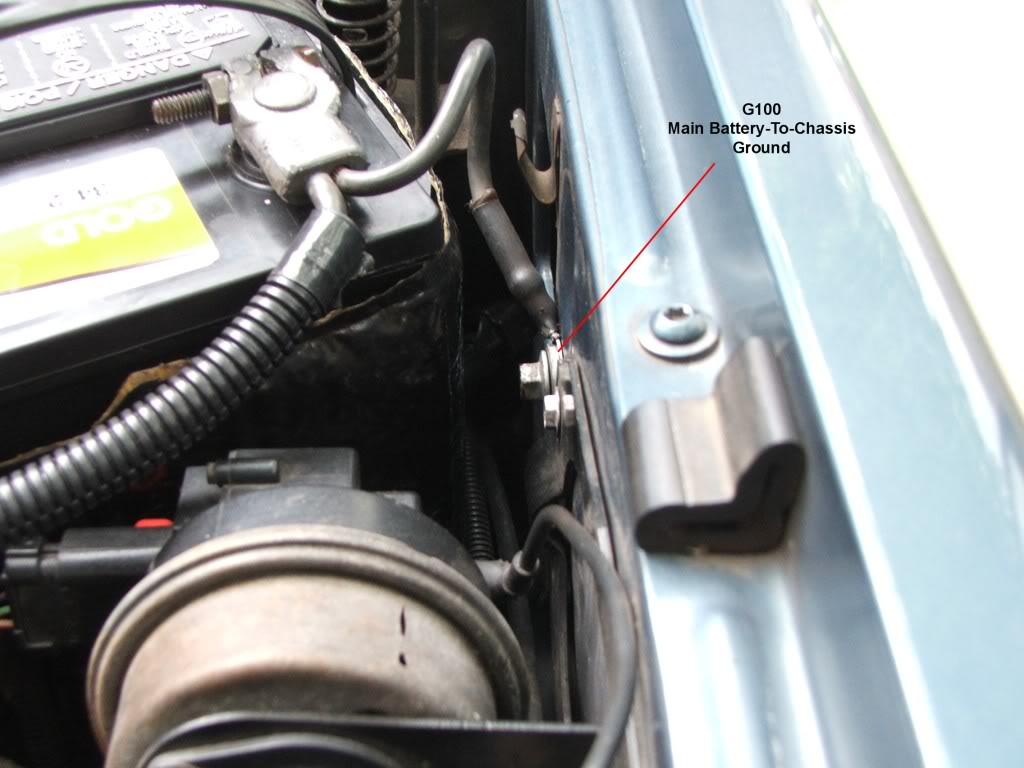

The main/primary ground from the battery to the chassis is from the battery negative post to the right inner fender. Called G100, and other designations in years prior to 1997 (see pic).

This ground point should be disassembled, cleaned free of corrosion, then reassembled securely.

Radio Noise Suppressor:

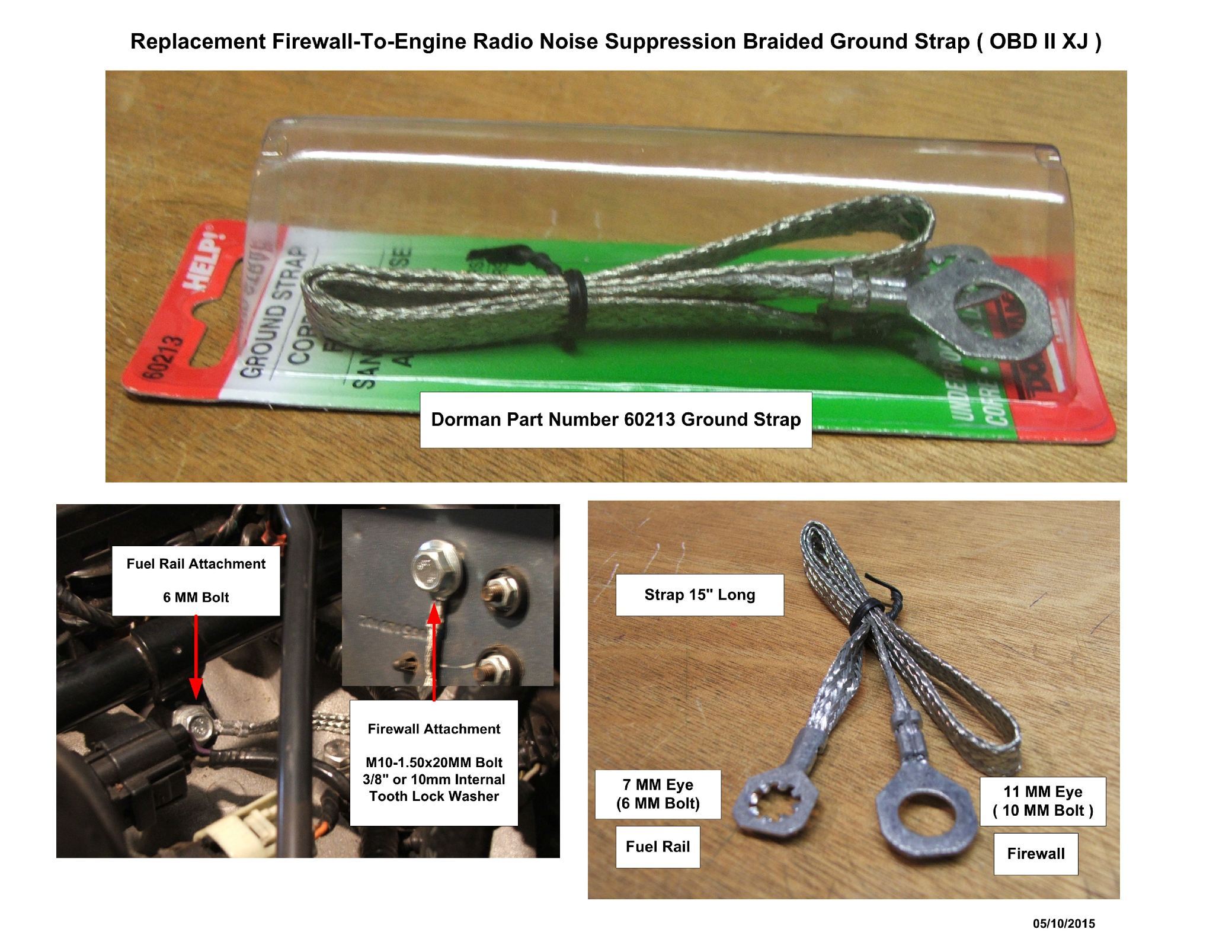

This bonding strap doesn't have to be a cable. Dorman makes a preassembled strap that works fine. See pic.

G100:

If you snap the head of the bolt off you can remove the bolt stub by removing the right front wheel and wheel well liner then turning the stub out using a pipe wrench. The bolt is an M8.

Do this and consider other sensors, connectors, or wiring being at fault for your no start/rough running.

The following users liked this post:

318SixPack (01-30-2022)

#6

Junior Member

Join Date: Jan 2022

Location: New York

Posts: 52

Likes: 0

Received 7 Likes

on

7 Posts

Year: 2000

Model: Cherokee (XJ)

Engine: 4.0 6L

Can I assume that when you say "crank" you mean start as opposed to turning the engine over with the starter motor.

There are a number of things that can cause an engine to intermittently not start, or run rough and misfire, but I don't think that the bonding strap from the firewall to #14 cylinder head bolt would be one of the causes.

That bonding strap is for Radio Noise Suppression and was never intended to be a primary ground (see pic).

The main/primary ground from the battery to the chassis is from the battery negative post to the right inner fender. Called G100, and other designations in years prior to 1997 (see pic).

This ground point should be disassembled, cleaned free of corrosion, then reassembled securely.

Radio Noise Suppressor:

Attachment 310389

This bonding strap doesn't have to be a cable. Dorman makes a preassembled strap that works fine. See pic.

Attachment 310390

G100:

Attachment 310391

If you snap the head of the bolt off you can remove the bolt stub by removing the right front wheel and wheel well liner then turning the stub out using a pipe wrench. The bolt is an M8.

Attachment 310392

Do this and consider other sensors, connectors, or wiring being at fault for your no start/rough running.

There are a number of things that can cause an engine to intermittently not start, or run rough and misfire, but I don't think that the bonding strap from the firewall to #14 cylinder head bolt would be one of the causes.

That bonding strap is for Radio Noise Suppression and was never intended to be a primary ground (see pic).

The main/primary ground from the battery to the chassis is from the battery negative post to the right inner fender. Called G100, and other designations in years prior to 1997 (see pic).

This ground point should be disassembled, cleaned free of corrosion, then reassembled securely.

Radio Noise Suppressor:

Attachment 310389

This bonding strap doesn't have to be a cable. Dorman makes a preassembled strap that works fine. See pic.

Attachment 310390

G100:

Attachment 310391

If you snap the head of the bolt off you can remove the bolt stub by removing the right front wheel and wheel well liner then turning the stub out using a pipe wrench. The bolt is an M8.

Attachment 310392

Do this and consider other sensors, connectors, or wiring being at fault for your no start/rough running.

Last edited by fr3dbilli3; 01-29-2022 at 06:59 PM.

#7

Member

you dug up a 6 year old thread to ask a guy that hasn't logged in since 2017 a question that he answered in the quote you attached to your thread.

The following users liked this post:

99to00JeepLaredo (02-22-2023)

Trending Topics

#8

Member

don't drive without a ground attached. if you drill a new hole how are you going to fasten a new ground stud without accessing from behind the fender? remove tire and fix the original ground stud.

#9

Senior Member

Glad your using the SEARCH on the forum to find answers to problems. Good Job!

You can not have enough GOOD grounds on you Jeep.

I made my own ground wires, and moved the ground point from where it was originally as I had to install my E Fan relays right there.

So I ended up making a 2AWG wire that goes from the battery to the front of my radiator bulkhead.

It attaches to the hood latch bolt. I also added a star washer on the back side of the copper lug to eat into that area of the body to make a better connection.

You don't have to do what I did, but you you can mount that ground anywhere close to the battery.

If it is going anywhere new, you must scratch away the paint where it mounts to first.

After you install the wire, give it a coat of paint so it does not rust.

You can not have enough GOOD grounds on you Jeep.

I made my own ground wires, and moved the ground point from where it was originally as I had to install my E Fan relays right there.

So I ended up making a 2AWG wire that goes from the battery to the front of my radiator bulkhead.

It attaches to the hood latch bolt. I also added a star washer on the back side of the copper lug to eat into that area of the body to make a better connection.

You don't have to do what I did, but you you can mount that ground anywhere close to the battery.

If it is going anywhere new, you must scratch away the paint where it mounts to first.

After you install the wire, give it a coat of paint so it does not rust.

Last edited by DustyWagoneer; 01-29-2022 at 11:33 PM.

#10

Newbie

Join Date: Feb 2023

Posts: 1

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee (XJ)

Engine: 4.0

Did tree ever find out the issue? Searched his page and found nothing. Iíve got the exact same issue in my Cherokee and have had it for some time. Iíve been scratching my head for ages and noticed my ground strap on the back of the engine is broken in half. Thanks

#11

Senior Member

Definitely replace that ground wire. It provides a good ground to the head and thus the spark plug ground path. The head will also be grounded through the head bolts, etc. but as Dusty already said you can't have enough good grounds. Also don't use antiseize on spark plug threads as most antiseize compounds are not a good electrical conductor.

#12

CF Veteran

Join Date: Dec 2017

Posts: 3,889

Received 1,065 Likes

on

856 Posts

Year: 1989

Model: Comanche (MJ)

Engine: 4.0

I've never heard of that being an issue, and the plugs will make a good connection regardless of antiseize on the threads. The Jeep heads are cast iron, so not as critical as aluminum heads. You really must use a touch of antiseize on aluminum heads unless you hate the next guy changing the plugs.

#13

Senior Member

In fact as most, anti-seize is copper or aluminium based, both of which are good conductors, it can only help, just as it does on battery terminals.

Don't know how you can shear the head off a bolt when the nut it's screwed into is only attached to the inner fender with pigeon spit, b-t-w it's M6, M8 is an upgrade.

I have a couple of relays there, they're mounted on that bolt or, possibly, a slightly longer one.

Don't know how you can shear the head off a bolt when the nut it's screwed into is only attached to the inner fender with pigeon spit, b-t-w it's M6, M8 is an upgrade.

I have a couple of relays there, they're mounted on that bolt or, possibly, a slightly longer one.

#14

Senior Member

I've never heard of that being an issue, and the plugs will make a good connection regardless of antiseize on the threads. The Jeep heads are cast iron, so not as critical as aluminum heads. You really must use a touch of antiseize on aluminum heads unless you hate the next guy changing the plugs.

From Autolite web site: The nickel coating on most modern spark plugs provided added protection from seizing in aluminum cylinder heads and has made anti-seize less important in spark plug installations. Anti-Sieze can alter the tightening torque up to 20%, increasing the risk of breakage. It can also create heat transfer and electrical conductivity concerns.

https://www.autolite.com/resources/tech-tips

From NGK wesite: NGK spark plugs are installed at the factory dry, without lubrication or anti-seizeÖ. Do not use anti-seize or lubricant on NGK spark plugs. It is completely unnecessary and can be detrimental.

https://ngksparkplugs.com/en/resourc...hell%20stretch.

From FCP Euro: Two of the most-asked about applications we get are, "should you use anti-seize on spark plugs" and "should you use anti-seize on lug nuts?" The answer to both of those is no! Neither application requires anti-seize, and in fact, in both, you run the risk of doing damage.

https://blog.fcpeuro.com/6-tips-for-...-of-anti-seize

Years ago Porsche published a bulletin recommending against the use of anti-seize for reasons of over torqueing and loss of a quality electrical ground. (Porsche Technical Bulletin 9102, Group 2 identifier 2870)

If you really want to use anti-seize take the time to understand the correct type applied in the right place in the right amount and with the necessary torque reduction. Otherwise there is a risk of more harm than good. Or just go with the spark plug and engine manufactures recommendation. There is a lot of sound information and misinformation on anti-seize. I donít intend to debate it further.

#15

Senior Member

All that seems to be about very different engines than we're dealing with, the plug manufacturers don't agree - & there's nothing from Champion.

Who torques plugs anyway? So we can disregard that. Antiseize will minimise the risk of breaking a plug when trying to remove it (& of stripping the thread in an aly head) so I've no intention of changing the habit of a lifetime with proven real real world benefits. But - that's just me, & everyone else is free to do their own thing.

Who torques plugs anyway? So we can disregard that. Antiseize will minimise the risk of breaking a plug when trying to remove it (& of stripping the thread in an aly head) so I've no intention of changing the habit of a lifetime with proven real real world benefits. But - that's just me, & everyone else is free to do their own thing.