Prothane Coil Bumps

#1

Banned

Thread Starter

Join Date: Oct 2013

Location: WNY

Posts: 933

Likes: 0

Received 45 Likes

on

45 Posts

Year: 2000

Model: Cherokee

Engine: 4.0

I've read a few threads on other forums about these, but not too many on here. I know some of you run them so I was hoping to get feedback.

I already have the 10.5" ones that I will cut as needed. I am getting UHMW rod to use as a hard stop inside. And am fabbing a plate for the upper jounce tower without cutting anything, incase I want to go back to OEM jounces.

I guess my question is what air gap have you the best on road feel, how have they lasted, do they affect flex as much as some say, etc.

I def do NOT jump my jeep, nor do I cruise whoops or dunes at 60. But I DO like to cruise down logging roads to get to wheeling spots. And do go down some access roads that have whoops that even at 30mph with OEM bumps feel harsh. I'm also looking for cushion for drop offs when crawling.

I already have the 10.5" ones that I will cut as needed. I am getting UHMW rod to use as a hard stop inside. And am fabbing a plate for the upper jounce tower without cutting anything, incase I want to go back to OEM jounces.

I guess my question is what air gap have you the best on road feel, how have they lasted, do they affect flex as much as some say, etc.

I def do NOT jump my jeep, nor do I cruise whoops or dunes at 60. But I DO like to cruise down logging roads to get to wheeling spots. And do go down some access roads that have whoops that even at 30mph with OEM bumps feel harsh. I'm also looking for cushion for drop offs when crawling.

#2

Beach Bum

Sounds like my adventures, lol.

I have run these things in all types of configurations, 1/2" gap, 2" gap, with and without internal stops, 4 ring, 5 ring and 6 ring.

Seems 2" gap works best.

Tower will still need some type of bump to make contact with prothane cap. Something more substantial than the stock foam jounce bumpers.

I wanted to avoid using UHMW. Instead I used cutoffs from Daystar extended bumpstops for XJ. It is a hard durometer rubber/poly that will suffice for a hard stop. The Daystars I used in the bumptowers, kept about 2" exposed and cut the rest off.

Cap should be slightly smaller than the flat spot on top of prothanes. If sized to match flat top, cap will knock on springs.

I made a threaded cap that inserts into prothanes. Be sure to add length of threaded insert to length of hard stop to get a measurement for final stop.

Not sure if you have seen my posts and pictures elsewhere, so I'm not elaborating too much here to just repeat myself. But am glad to help or offer more insight.

I have run these things in all types of configurations, 1/2" gap, 2" gap, with and without internal stops, 4 ring, 5 ring and 6 ring.

Seems 2" gap works best.

Tower will still need some type of bump to make contact with prothane cap. Something more substantial than the stock foam jounce bumpers.

I wanted to avoid using UHMW. Instead I used cutoffs from Daystar extended bumpstops for XJ. It is a hard durometer rubber/poly that will suffice for a hard stop. The Daystars I used in the bumptowers, kept about 2" exposed and cut the rest off.

Cap should be slightly smaller than the flat spot on top of prothanes. If sized to match flat top, cap will knock on springs.

I made a threaded cap that inserts into prothanes. Be sure to add length of threaded insert to length of hard stop to get a measurement for final stop.

Not sure if you have seen my posts and pictures elsewhere, so I'm not elaborating too much here to just repeat myself. But am glad to help or offer more insight.

#3

Banned

Thread Starter

Join Date: Oct 2013

Location: WNY

Posts: 933

Likes: 0

Received 45 Likes

on

45 Posts

Year: 2000

Model: Cherokee

Engine: 4.0

You were actually the first person I had in mind haha. I know others run them, but I've seen your posts before on them. Also read through the Naxja and JF threads on them.

I already have the UHMW rod on order, should be coming today, so I'm just going to use that for now. I need 4.25" of hard stop. I have 9.5" of space between bottom bucket and jounce tower(without rubber jounce).

My plan, is to cut the prothane to 8" first, leaving a 1.5" air gap. I will use a 4.25" UHMW piece as the hard stop. For the top tower, since I have the newer style that is welded not screwed, I drilled and tapped a hole and will bolt in some type of washer to make the plate. I see everyone doing like you did with the plate on the prothane, and just want to avoid problems with it coming out, also less work for me to do, with less moving parts.

Right now I have an extra thick 2" washer which is the same diameter as the tower, I am getting a 2.5" one today to use as well to ensure the prothane doesn't get impaled.

I already have the UHMW rod on order, should be coming today, so I'm just going to use that for now. I need 4.25" of hard stop. I have 9.5" of space between bottom bucket and jounce tower(without rubber jounce).

My plan, is to cut the prothane to 8" first, leaving a 1.5" air gap. I will use a 4.25" UHMW piece as the hard stop. For the top tower, since I have the newer style that is welded not screwed, I drilled and tapped a hole and will bolt in some type of washer to make the plate. I see everyone doing like you did with the plate on the prothane, and just want to avoid problems with it coming out, also less work for me to do, with less moving parts.

Right now I have an extra thick 2" washer which is the same diameter as the tower, I am getting a 2.5" one today to use as well to ensure the prothane doesn't get impaled.

#4

Beach Bum

Under suspension compression, even a 2.5" washer mounted on tower will likely sink into center 1.5" hole in prothane.

Not sure what you mean by tower welded not screwed. On my 96 the jounce bumper is simply pressed into tower.

I used a piece of 4" long galvanized all-thread that is tapered. Cut it in half and welded to a flat washer.

Think I still have the first pair of prothane caps laying around if you are interested.

Not sure what you mean by tower welded not screwed. On my 96 the jounce bumper is simply pressed into tower.

I used a piece of 4" long galvanized all-thread that is tapered. Cut it in half and welded to a flat washer.

Think I still have the first pair of prothane caps laying around if you are interested.

#5

Banned

Thread Starter

Join Date: Oct 2013

Location: WNY

Posts: 933

Likes: 0

Received 45 Likes

on

45 Posts

Year: 2000

Model: Cherokee

Engine: 4.0

Under suspension compression, even a 2.5" washer mounted on tower will likely sink into center 1.5" hole in prothane. Not sure what you mean by tower welded not screwed. On my 96 the jounce bumper is simply pressed into tower. I used a piece of 4" long galvanized all-thread that is tapered. Cut it in half and welded to a flat washer. Think I still have the first pair of prothane caps laying around if you are interested.

You really think a 2.5" washer will still impale the prothane? I really don't want a plate just sitting on top of the prothane, it's more work for me as I would have to pay someone to weld, and more parts than I want in the setup; plate with tube welded, OEM jounce, etc. The next size is a 3" hockey puck I was going to bolt to the tower, but that doesn't fit through the top of the coil so it would get hung up if I flexed that much, don't even know if I could flex that much though without contacting something else.

#6

Beach Bum

I understand now what welds you were referring to.

The cap in picture was my first attempt and it eventually pushed into prothane. I made larger ones.

You have good ideas so experiment as you wish, that is how I figured it out.

Perhaps you could drill trough center of UHMW, bolt or screw it to a 3" washer with a button head bolt/screw. UHMW would hold the cap in place. Then install the daystars in tower.

The cap in picture was my first attempt and it eventually pushed into prothane. I made larger ones.

You have good ideas so experiment as you wish, that is how I figured it out.

Perhaps you could drill trough center of UHMW, bolt or screw it to a 3" washer with a button head bolt/screw. UHMW would hold the cap in place. Then install the daystars in tower.

#7

Banned

Thread Starter

Join Date: Oct 2013

Location: WNY

Posts: 933

Likes: 0

Received 45 Likes

on

45 Posts

Year: 2000

Model: Cherokee

Engine: 4.0

I understand now what welds you were referring to. The cap in picture was my first attempt and it eventually pushed into prothane. I made larger ones. You have good ideas so experiment as you wish, that is how I figured it out. Perhaps you could drill trough center of UHMW, bolt or screw it to a 3" washer with a button head bolt/screw. UHMW would hold the cap in place. Then install the daystars in tower.

Trending Topics

#9

Beach Bum

I think the tower should have a bumper in it.

Keep in mind the long tower, making contact at its end, provides a lot of leverage to bend tower. And the towers were not designed to take the repetitive loads the prothanes put on them.

With that said, mine are holding up and do not seem to be deforming with the hard rubber Daystars.

Keep in mind the long tower, making contact at its end, provides a lot of leverage to bend tower. And the towers were not designed to take the repetitive loads the prothanes put on them.

With that said, mine are holding up and do not seem to be deforming with the hard rubber Daystars.

#10

Banned

Thread Starter

Join Date: Oct 2013

Location: WNY

Posts: 933

Likes: 0

Received 45 Likes

on

45 Posts

Year: 2000

Model: Cherokee

Engine: 4.0

I think the tower should have a bumper in it. Keep in mind the long tower, making contact at its end, provides a lot of leverage to bend tower. And the towers were not designed to take the repetitive loads the prothanes put on them. With that said, mine are holding up and do not seem to be deforming with the hard rubber Daystars.

#11

Beach Bum

Cut + drill UHMW with wood tools and sharp drill bit. But not a skill saw or other blade that travels fast. It will melt the material and gum up.

Hand saw works well and a router can be used for edges. When drilling, use a slow to medium speed because the material will quickly 'pull' the bit into and completely through before you can stop bit.

I represented a manufacturer of UHMW for a few years, selling to the marine industry.

Hand saw works well and a router can be used for edges. When drilling, use a slow to medium speed because the material will quickly 'pull' the bit into and completely through before you can stop bit.

I represented a manufacturer of UHMW for a few years, selling to the marine industry.

#12

Banned

Thread Starter

Join Date: Oct 2013

Location: WNY

Posts: 933

Likes: 0

Received 45 Likes

on

45 Posts

Year: 2000

Model: Cherokee

Engine: 4.0

All I have are metal cutting bits and taps. I have 0 woodworking tools, not even a saw haha.

I can drill slow with the bits I have, my hand drill can go real slow.

I might configure it a different route too, going to play around with it some more today.

I can drill slow with the bits I have, my hand drill can go real slow.

I might configure it a different route too, going to play around with it some more today.

#14

Beach Bum

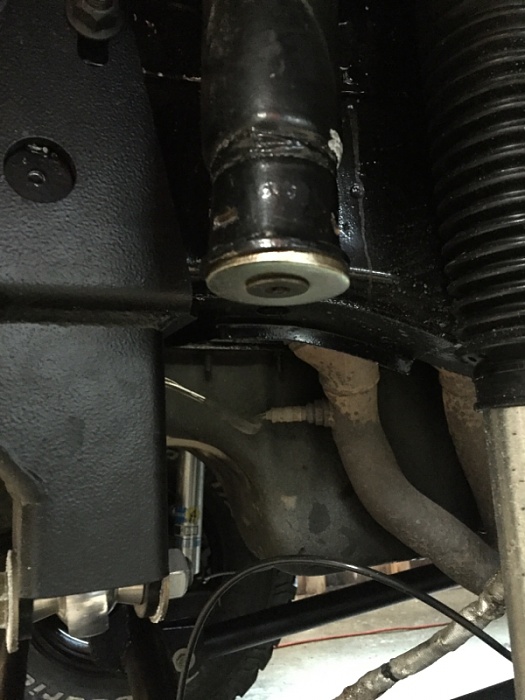

That looks good. Seeing it helps, it will not push through.

FYI, bits/taps for metal will work exceptionally well on UHMW.

To secure prothane to coil bucket and keep them from bouncing around, I mounted a short stack of 1.5" diameter washers to the coil bucket.

FYI, bits/taps for metal will work exceptionally well on UHMW.

To secure prothane to coil bucket and keep them from bouncing around, I mounted a short stack of 1.5" diameter washers to the coil bucket.

Last edited by SteveMongr; 01-29-2016 at 11:41 AM.

#15

Banned

Thread Starter

Join Date: Oct 2013

Location: WNY

Posts: 933

Likes: 0

Received 45 Likes

on

45 Posts

Year: 2000

Model: Cherokee

Engine: 4.0