Welding thread!!!!

#61

what do you guys think about the eastwood welders. i have personally use other eastwood product and they have been very good quality. This welders seems seems like a very good and reasanoble price. any input would be great there is a 135 and a 175. here is a lik at the one im looking at currently:

http://www.eastwood.com/mig-welders-...spool-gun.html

http://www.eastwood.com/mig-welders-...spool-gun.html

#63

CF Veteran

Join Date: Nov 2011

Location: City of Trees, CA

Posts: 7,387

Likes: 0

Received 10 Likes

on

9 Posts

Year: 93 2 door

Model: Cherokee

Engine: 4.0

a grinder? plasma is too messy.

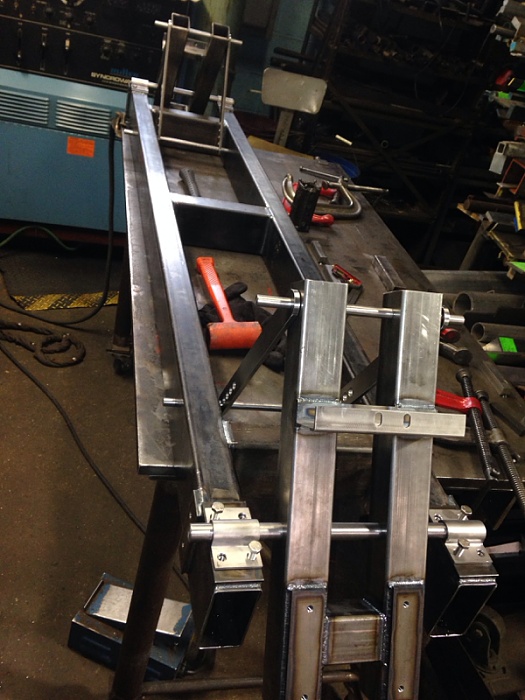

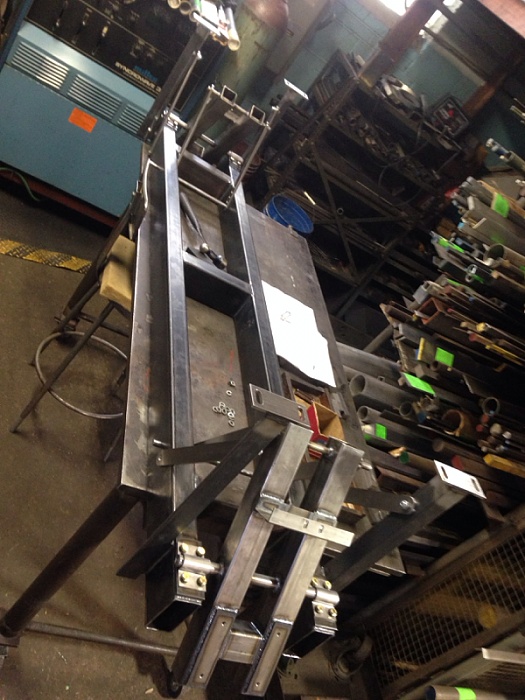

the rest of the frame plates are premaid from HDOffroad. but I cut out the rocker tie in, the floor plating, and the brackets, and drilled all the holes..

the rest of the frame plates are premaid from HDOffroad. but I cut out the rocker tie in, the floor plating, and the brackets, and drilled all the holes..

#64

CF Veteran

Join Date: Dec 2012

Location: York, PA

Posts: 4,169

Likes: 0

Received 6 Likes

on

6 Posts

Year: 1998

Model: Cherokee

Engine: 4.0

what do you guys think about the eastwood welders. i have personally use other eastwood product and they have been very good quality. This welders seems seems like a very good and reasanoble price. any input would be great there is a 135 and a 175. here is a lik at the one im looking at currently:

http://www.eastwood.com/mig-welders-...spool-gun.html

http://www.eastwood.com/mig-welders-...spool-gun.html

#65

I saw your post i was wondering would you use that to weld a bumper? does it weld 1/4 inch good? i think thats the thickest i would be welding with. that would be great because it would save me about 300.00 dollars

Last edited by angel1168; 01-13-2014 at 03:18 PM. Reason: all kind of fu** up grammer

#75

Ill play along! ive been welding for about 6 years now, learned in high school shop classes and bought myself a cheap Lincoln Flux core with my first paycheck ever. Been using it for the last 6 years. I have made a TON of projects with this (built 2 derby cars). But ive finally splurged and bought myself a Hobart Handler 140.

PICS!

This is the lincoln weld pak. Ive grown attached to this lil guy.

And the new baby. withmy new helmet, and 155 tank set up. I can already tell im going to love this thing!

OHH and heres my new helmet! Its a Rhino helmet with a HUGE lens. Its so nice how much you can see through it.

PICS!

This is the lincoln weld pak. Ive grown attached to this lil guy.

And the new baby. withmy new helmet, and 155 tank set up. I can already tell im going to love this thing!

OHH and heres my new helmet! Its a Rhino helmet with a HUGE lens. Its so nice how much you can see through it.

Last edited by tmj91; 01-16-2014 at 12:39 PM.