Welding thread!!!!

#2146

Junior Member

Join Date: Nov 2015

Location: central maine

Posts: 56

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1991

Model: Cherokee

Engine: 4.0

thanks for the advice I kinda listen to everybody didn't grind flush but ground smooth and dropped wire speed and slowed way down, so its like 2.5 full passes now, I just didn't get a picture

#2147

::CF Administrator::

#2149

::CF Administrator::

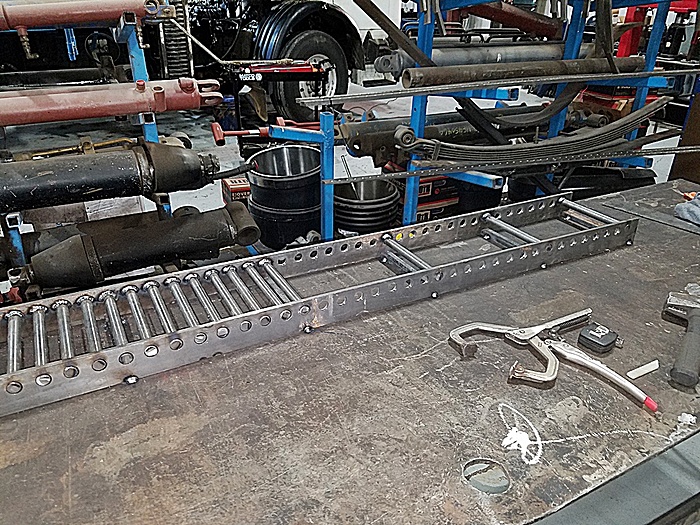

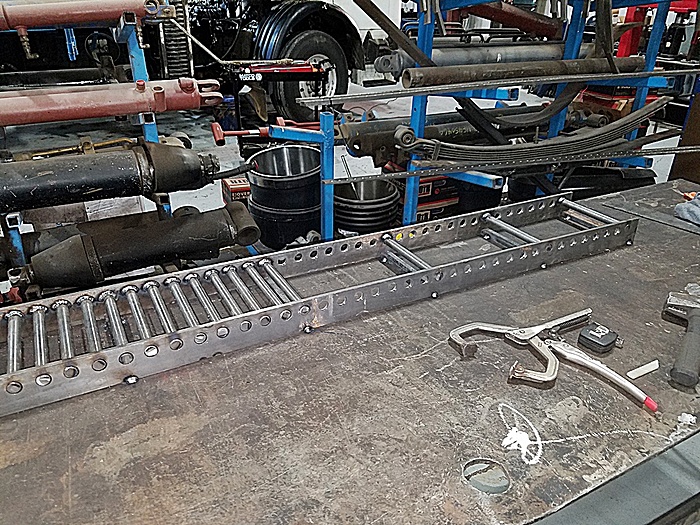

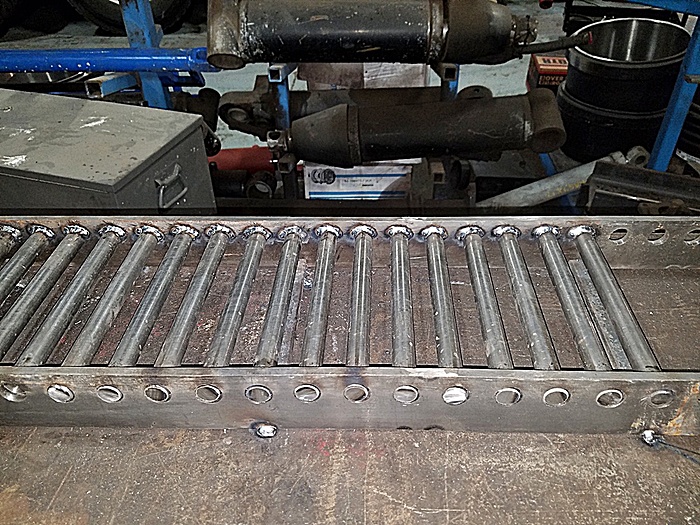

What I did in about 2 hours of "free time" today, LOL...free time meaning not putting out any fires...

Built up a jig on the welding table to make some ladder assemblies for the grabber arms on some of our trucks...simple stuff, but I still think it's cool...nice change of pace

Side pieces set up, one side tacked, with the spacer jigs tacked in...

Quick fit check to double check dimensions are good with the cross bars

Other side rail tacked in, and cross bars tacked in every foot...

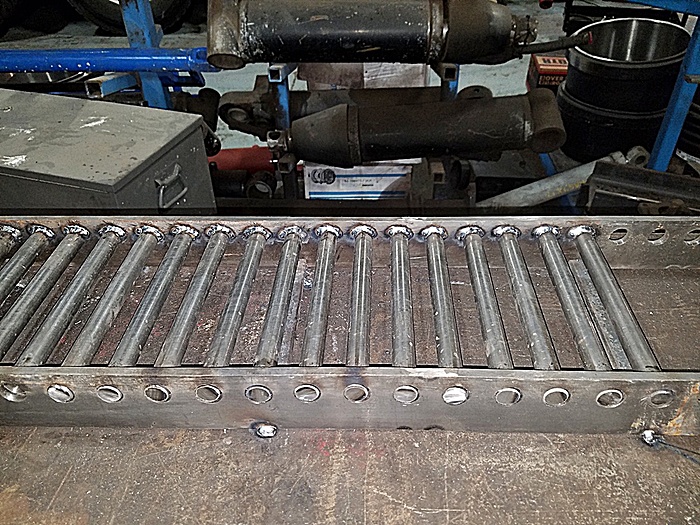

Got the rest of the cross bars (short some, waiting on 3/4" round stock to finish) in place...

Welded in what I could, both sides...will have the rest of the round stock in early next week. 3 more to build after that, should go quickly...

Built up a jig on the welding table to make some ladder assemblies for the grabber arms on some of our trucks...simple stuff, but I still think it's cool...nice change of pace

Side pieces set up, one side tacked, with the spacer jigs tacked in...

Quick fit check to double check dimensions are good with the cross bars

Other side rail tacked in, and cross bars tacked in every foot...

Got the rest of the cross bars (short some, waiting on 3/4" round stock to finish) in place...

Welded in what I could, both sides...will have the rest of the round stock in early next week. 3 more to build after that, should go quickly...

#2151

Moderator CF K9-unit

Join Date: Apr 2012

Location: Alaska

Posts: 5,842

Likes: 0

Received 9 Likes

on

8 Posts

Year: 2000 sport

Model: Cherokee (XJ)

Engine: New 4.0l from s&j engines

What I did in about 2 hours of "free time" today, LOL...free time meaning not putting out any fires...

Built up a jig on the welding table to make some ladder assemblies for the grabber arms on some of our trucks...simple stuff, but I still think it's cool...nice change of pace

Side pieces set up, one side tacked, with the spacer jigs tacked in...

Attachment 299319

Attachment 299320

Quick fit check to double check dimensions are good with the cross bars

Attachment 299321

Attachment 299322

Attachment 299323

Other side rail tacked in, and cross bars tacked in every foot...

Attachment 299324

Attachment 299325

Got the rest of the cross bars (short some, waiting on 3/4" round stock to finish) in place...

Attachment 299326

Attachment 299327

Welded in what I could, both sides...will have the rest of the round stock in early next week. 3 more to build after that, should go quickly...

Attachment 299328

Attachment 299329

Attachment 299330

Built up a jig on the welding table to make some ladder assemblies for the grabber arms on some of our trucks...simple stuff, but I still think it's cool...nice change of pace

Side pieces set up, one side tacked, with the spacer jigs tacked in...

Attachment 299319

Attachment 299320

Quick fit check to double check dimensions are good with the cross bars

Attachment 299321

Attachment 299322

Attachment 299323

Other side rail tacked in, and cross bars tacked in every foot...

Attachment 299324

Attachment 299325

Got the rest of the cross bars (short some, waiting on 3/4" round stock to finish) in place...

Attachment 299326

Attachment 299327

Welded in what I could, both sides...will have the rest of the round stock in early next week. 3 more to build after that, should go quickly...

Attachment 299328

Attachment 299329

Attachment 299330

How much for that new one..Ill let them know who to call,,, lol

#2152

CF Veteran

Join Date: May 2012

Location: Lost in the wilds of Virginia

Posts: 7,964

Received 952 Likes

on

767 Posts

Year: 1998 Classic (I'll get it running soon....) and 02 Grand

Model: Cherokee (XJ)

Engine: 4.0

Hey, ladies, a question about weld-through primer. A member here told me about it, and I got some from Amazon. 3M. I see it has a high zinc content. I have been warned about the dangers of welding galvanized metal because the zinc makes a nasty toxic gas when welded.

So why is it okay to weld through a primer that is high in zinc?

And would it be okay to use a high-zinc cold galvanize paint as a weld-through primer?

Getting ready for a major rust fixing project on my Jeep. I'll be cutting up my scrapped 94 for practice pieces!

So why is it okay to weld through a primer that is high in zinc?

And would it be okay to use a high-zinc cold galvanize paint as a weld-through primer?

Getting ready for a major rust fixing project on my Jeep. I'll be cutting up my scrapped 94 for practice pieces!

#2153

CF Veteran

Join Date: Oct 2016

Location: CA

Posts: 1,535

Likes: 0

Received 7 Likes

on

4 Posts

Year: 1994

Model: Cherokee (XJ)

What I did in about 2 hours of "free time" today, LOL...free time meaning not putting out any fires...

Built up a jig on the welding table to make some ladder assemblies for the grabber arms on some of our trucks...simple stuff, but I still think it's cool...nice change of pace

Side pieces set up, one side tacked, with the spacer jigs tacked in...

Attachment 299319

Attachment 299320

Quick fit check to double check dimensions are good with the cross bars

Attachment 299321

Attachment 299322

Attachment 299323

Other side rail tacked in, and cross bars tacked in every foot...

Attachment 299324

Attachment 299325

Got the rest of the cross bars (short some, waiting on 3/4" round stock to finish) in place...

Attachment 299326

Attachment 299327

Welded in what I could, both sides...will have the rest of the round stock in early next week. 3 more to build after that, should go quickly...

Attachment 299328

Attachment 299329

Attachment 299330

Built up a jig on the welding table to make some ladder assemblies for the grabber arms on some of our trucks...simple stuff, but I still think it's cool...nice change of pace

Side pieces set up, one side tacked, with the spacer jigs tacked in...

Attachment 299319

Attachment 299320

Quick fit check to double check dimensions are good with the cross bars

Attachment 299321

Attachment 299322

Attachment 299323

Other side rail tacked in, and cross bars tacked in every foot...

Attachment 299324

Attachment 299325

Got the rest of the cross bars (short some, waiting on 3/4" round stock to finish) in place...

Attachment 299326

Attachment 299327

Welded in what I could, both sides...will have the rest of the round stock in early next week. 3 more to build after that, should go quickly...

Attachment 299328

Attachment 299329

Attachment 299330

#2154

CF Veteran

Join Date: Jul 2012

Location: San Antonio, TX

Posts: 4,104

Likes: 0

Received 2 Likes

on

2 Posts

Year: 1996

Model: Cherokee

Engine: 4.0L

almost bought a co2 argon tank today, but i needed shelving for my garage more than i needed a bottle right this second.

next project after the lsxj is driving right will be the stiffner install

next project after the lsxj is driving right will be the stiffner install

#2155

CF Veteran

Join Date: Oct 2016

Location: CA

Posts: 1,535

Likes: 0

Received 7 Likes

on

4 Posts

Year: 1994

Model: Cherokee (XJ)

Hey, ladies, a question about weld-through primer. A member here told me about it, and I got some from Amazon. 3M. I see it has a high zinc content. I have been warned about the dangers of welding galvanized metal because the zinc makes a nasty toxic gas when welded.

So why is it okay to weld through a primer that is high in zinc?

And would it be okay to use a high-zinc cold galvanize paint as a weld-through primer?

Getting ready for a major rust fixing project on my Jeep. I'll be cutting up my scrapped 94 for practice pieces!

So why is it okay to weld through a primer that is high in zinc?

And would it be okay to use a high-zinc cold galvanize paint as a weld-through primer?

Getting ready for a major rust fixing project on my Jeep. I'll be cutting up my scrapped 94 for practice pieces!

Weld thru primer is used in collision repair to replace the zinc coating imbedded in sheet metal panels only when it is ground off during the repair. It was designed to be used ONLY on bare metal mating flanges where special spot welders are used. It has very poor adhesion properties and will fail and peel if used on surfaces other than the inside flanges in a pinch weld. It's one of the most misunderstood, and misused products in the industry. Some auto manufactures do not even allow it in their repair procedures at all.

If you're going to use it for something like frame stiffeners, only spray it on the back side of the stiffener. Dont coat your entire unibody rail with it. You're also correct about it being toxic and DO NOT, use cold galv anywhere near a welder.

#2157

No, I don't lick fish.

Weld thru primer is used in collision repair to replace the zinc coating imbedded in sheet metal panels only when it is ground off during the repair. It was designed to be used ONLY on bare metal mating flanges where special spot welders are used. It has very poor adhesion properties and will fail and peel if used on surfaces other than the inside flanges in a pinch weld. It's one of the most misunderstood, and misused products in the industry. Some auto manufactures do not even allow it in their repair procedures at all.

If you're going to use it for something like frame stiffeners, only spray it on the back side of the stiffener. Dont coat your entire unibody rail with it. You're also correct about it being toxic and DO NOT, use cold galv anywhere near a welder.

If you're going to use it for something like frame stiffeners, only spray it on the back side of the stiffener. Dont coat your entire unibody rail with it. You're also correct about it being toxic and DO NOT, use cold galv anywhere near a welder.

#2159

CF Veteran

Join Date: May 2012

Location: Lost in the wilds of Virginia

Posts: 7,964

Received 952 Likes

on

767 Posts

Year: 1998 Classic (I'll get it running soon....) and 02 Grand

Model: Cherokee (XJ)

Engine: 4.0

I'm just a rookie welder, but two things I know:

- Don't weld zinc.

- Don't weld brake fluid.

Okay, so how is it possible to weld brake fluid? Simple, use it to clean parts, then weld them. It hangs around. Any hidden little pocket can ruin your life, and possibly kill you. When subjected to the high heat of the arc, it forms phosgene, which was used in WWI as a poison gas. Nasty stuff.

I believe it's the older, more effective chlorinated brake cleaner that is dangerous, and the new stuff is supposedly safe, but I think I'll just stay away from either kind.

#2160

No, I don't lick fish.

Definitely welding related... Also strong language, so be warned.

Im dying laughing right now.

https://www.youtube.com/watch?v=bABCvucGATc

Im dying laughing right now.

https://www.youtube.com/watch?v=bABCvucGATc

I'm just a rookie welder, but two things I know:

Okay, so how is it possible to weld brake fluid? Simple, use it to clean parts, then weld them. It hangs around. Any hidden little pocket can ruin your life, and possibly kill you. When subjected to the high heat of the arc, it forms phosgene, which was used in WWI as a poison gas. Nasty stuff.

I believe it's the older, more effective chlorinated brake cleaner that is dangerous, and the new stuff is supposedly safe, but I think I'll just stay away from either kind.

- Don't weld zinc.

- Don't weld brake fluid.

Okay, so how is it possible to weld brake fluid? Simple, use it to clean parts, then weld them. It hangs around. Any hidden little pocket can ruin your life, and possibly kill you. When subjected to the high heat of the arc, it forms phosgene, which was used in WWI as a poison gas. Nasty stuff.

I believe it's the older, more effective chlorinated brake cleaner that is dangerous, and the new stuff is supposedly safe, but I think I'll just stay away from either kind.

I've heard from several how-to's and welders that it's okay to use the non-chlorinated to clean or prep for welding, most say to just use alcohol... I guess acetone is okay too?