Welding thread!!!!

#2117

No, I don't lick fish.

#2121

CF Veteran

Join Date: Oct 2016

Location: CA

Posts: 1,535

Likes: 0

Received 7 Likes

on

4 Posts

Year: 1994

Model: Cherokee (XJ)

[ig]https://cimg5.ibsrv.net/gimg/www.cherokeeforum.com-vbulletin/2000x1504/80-img_0061_4258fd4d902c842a03dcdfe6478a2824f45c0ddb. jpg[/img]

[ig]https://cimg6.ibsrv.net/gimg/www.cherokeeforum.com-vbulletin/2000x1504/80-img_0066_ef8ce5354035da9d72285aef5e2c7e167e7e652e. jpg[/img]Disregard the mess

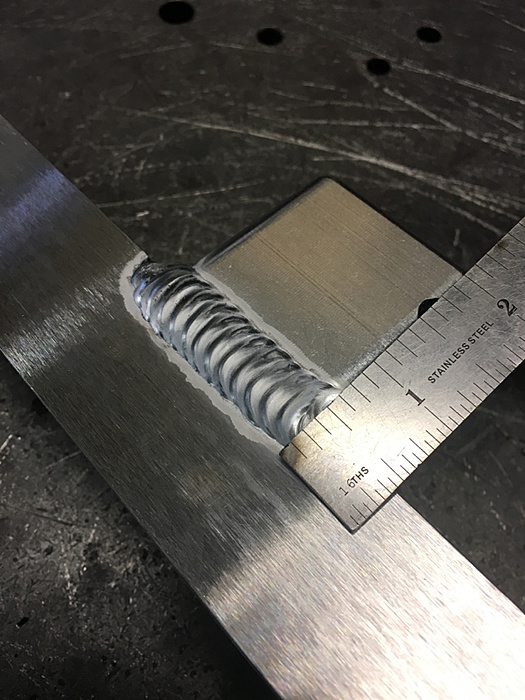

Had my brother and dad weld this up for me last week. Fits perfect in the rear.

[ig]https://cimg6.ibsrv.net/gimg/www.cherokeeforum.com-vbulletin/2000x1504/80-img_0066_ef8ce5354035da9d72285aef5e2c7e167e7e652e. jpg[/img]Disregard the mess

Had my brother and dad weld this up for me last week. Fits perfect in the rear.

Last edited by LACK; 02-20-2017 at 06:25 PM.

#2125

::CF Administrator::

#2126

CF Veteran

Stick welding is something else. I have only done it twice and it was not what I was expecting. Completely different then any other type of welding.

#2128

CF Veteran

Join Date: Feb 2013

Location: Belton S.C.

Posts: 1,286

Likes: 0

Received 1 Like

on

1 Post

Year: 1998

Model: Cherokee

Engine: 4.0

Just catching up on this thread. For the newbs looking to get started the Hobart 140 can't be beat for the price. Bought mine on CL for $400 with a small bottle. Built me a cart for it and stepped up to a larger bottle and couldn't be happier. For most DIY guys something like that is all you will likely need. I welded up my DBO DIY with mine on a regular 110v household outlet, and after killing a Nissan that pulled out in front of me, taking out two deer, a metal 55 gallon drum and countless small trees the welds have held up perfectly. I'm not a certified welder by any means, my dad taught me how to run a bead with a Miller thunderbolt that I still have today when I was about 12. I have been doing professional shaft repair welds, and fab for near 20 years and am considered to be one of the best in my area. The key to good welds is info and practice, practice, practice, practice x10. Lol. Oxy welding, as well as manual machinig is a quickly dying art.It sucks but also makes us that are able to do it more valuable. The more experience you get with it the more you realize that it truly is an art. Get out there and burn, turn, and cut some metal. The only limit to your skill is your determination.

#2130

CF Veteran

Join Date: Feb 2013

Location: Belton S.C.

Posts: 1,286

Likes: 0

Received 1 Like

on

1 Post

Year: 1998

Model: Cherokee

Engine: 4.0

Haha, thanks. That's why I said most DIY guys. I found that 3/16" is about the max I can do in a single pass with the 140, I can go thicker but have to run a root and cap style weld. If I need to do heavy duty stuff I break out the old thunderbolt, that thing is old as hell but is a beast.

I glad to see that people are still interested it learning the old metal arts, they are invaluable skills. In a world where we depend more and more on machines and computers to do everything for us, it's good to know that at least some of the next generation will keep the arts alive.