Headlight/Harness Upgrade: Step-by-Step Illustrated DIY write-up for total beginners

#1

Banned

Thread Starter

Join Date: Oct 2012

Location: USA

Posts: 1,744

Likes: 0

Received 1 Like

on

1 Post

Year: 1998

Model: Cherokee

Engine: 4.0L i6

This thread is to help beginners. That's why I wrote "beginner" in the title. Most here will consider this overkill.

But, just saying "Dude, harness install is dead simple, LOLZ" does not actually teach a beginner how to do anything.

B/c even something as simple as a rusted screw can stop a beginner with limited tools in his tracks.

Hopefully, this write-up will be useful for someone else going forward, and answer the questions I had myself.

Before I did this DIY, I had no idea what a relay even was.

Now, I understand their purpose and the basic idea of why a direct to battery harness with relayed switch is a better solution.

I went through the effort of writing up a very detailed how-to b/c I personally like to see all the steps before attempting a job.

I try to understand what I am getting into, and what problems I may encounter, and if it's a reasonable project to attempt with the basic tools I have.

If you found this write-up helpful, and the details and photos I've you the confidence to try this, please bump the thread, and share your results.

This job took me about 3 hours. A couple of obstacles that no one mentions:

PARTS:

I ordered this harness from Ebay for $36.

Some people have complained about the Putco relays. The Putco also does not have a fuse.

Others talk about splicing in better relays, but I'm no electrician. For another $10, I went with this, which is cheaper than splicing in relays to the $25 Putco.

Some have also said the Putco is short. I found the extra length to be helpful while snaking these cables around.

Here are the headlights for $44

These also come with the bulbs, so it's one less thing to have to learn about.

Make sure you order DOT approved, otherwise you might not pass inspection.

The Ebay seller has Euro "E" that are not USA legal, and he omits that little detail in his ad.

STEPS:

1) Disconnect the battery. You can just black negative terminal. Put a sock over it so it doesn't reconnect on accident.

2) Remove the headlight bezels. There are 2 screws on each side.

3) Remove the grille. There are 4 screws.

4) Remove the 4 screws that hold the headlight retainer bezel.

These are rusted and you will need to press hard to break them free.

I used PB blaster for a few days before the weekend.

One of my screws was stripped.

This added at least an hour to this job.

If this happens to you, you'll need to remove the turn signals out of the way before you begin to battle that screw.

First I tried screw extractors.

They are complete garbage and didn't do a thing.

Or, maybe I don't know how to use them.

I tried to use them in my drill, and they did nothing but carve a nice circle into the screw head.

Basically did what a (crappy) drill bit would do.

I then tried a dremel cutting wheel.

I was unable to get it flush enough, so it made no difference, and the screw still held the ring in.

I then tried a drill bit. It also did nothing.

When I did it, it just made a round cavity in the screw head.

And the hacked up screw still held the retainer ring firmly in place.

I think I might need to ask a professional mechanic to show me how to drill out a screw.

Or, next time, I will try an angle grinder and just obliterate the screw head entirely.

So, I gave up and realized that drilling out a screw is beyond my experience & ability level.

Instead, since I had gotten 3 out of 4 screws out, I just bent the retainer ring down to free the headlight.

Eventually, I just got pissed and ripped the retainer ring off the screw.

I tried to get this screw out by just bending it from behind with needlenose, but it was frozen solid.

5) Next, it's time to unplug the old headlights.

The plugs have been fastened for 15 years, so they are really stuck on.

Also, you need to pry apart the clip.

I had to use a screwdriver to gently pry off the clip.

There was no way to do it with bare hands.

6) Now, you need to connect the new harness.

Make sure you snake the cables backwards so you can tuck them away.

I hooked the red power to the fuse box power bolt.

7) Snake the cables to where they need to go.

This will take some time to see how it's routed.

Snake the driver's side across the grill where the original wiring goes.

In the grille, zip tie the long cable to the old cable

Feed each bulb connector into each housing.

Tip: Get under the Jeep to see where to route them.

You will connect the new harness into the old headlight socket.

8) Each new bulb socket has a ground wire.

I connected the passenger ground to the same ground where the negative battery terminal connects to.

I was confused where to ground the driver's side.

Here is what I did, and I don't know if that is correct.

9) Connect the new headlights to the new sockets.

You also need to install the bulb into the headlight.

The thing that you remove can be thrown away.

Don't forget to add the rubber boot before connecting.

11) Test the headlights.

Success!!! And way brighter than before!!

12) Secure the relay housing.

This was another detail no one mentions when they say this is a 15 mins. job.

There was no room to put it anywhere.

The one screw that was available was too high, and the hood would have hit the relays when closed,

I saw a cavity in the fender, but do not know if water comes in there.

Where did you screw yours to?

I had no idea where to put it, so I just tucked it away near the fuse box.

I did not screw it onto anything, but it's not going to move much.

I read that the relays can get wet, and there's a right way to install them.

(Upside down? Right side up? I was unable to understand the right way, and of course, no one ever posts a photo)

So, I just bagged the relays in saran wrap and rubbed banded it tight, and tucked it up near the fuse box.

Hope that works.

13) Reinstall the headlight retainer ring, grille, and bezels.

But, just saying "Dude, harness install is dead simple, LOLZ" does not actually teach a beginner how to do anything.

B/c even something as simple as a rusted screw can stop a beginner with limited tools in his tracks.

Hopefully, this write-up will be useful for someone else going forward, and answer the questions I had myself.

Before I did this DIY, I had no idea what a relay even was.

Now, I understand their purpose and the basic idea of why a direct to battery harness with relayed switch is a better solution.

I went through the effort of writing up a very detailed how-to b/c I personally like to see all the steps before attempting a job.

I try to understand what I am getting into, and what problems I may encounter, and if it's a reasonable project to attempt with the basic tools I have.

If you found this write-up helpful, and the details and photos I've you the confidence to try this, please bump the thread, and share your results.

This job took me about 3 hours. A couple of obstacles that no one mentions:

- One stripped screw will double the time required to do this job (screw extractors, cutting wheel dremel, angle grinder, and various drill bits)

Do not even think about working on a Jeep if you don't own these tools. - It was also unclear where to ground the new grounds. Had to try a few places.

- I also tried a few different places to mount the relays.

- B/c of this, I had to redo the routing of the wiring a couple of times.

- It was also hard to unplug the headlights. This took longer than expected, and I had to use a screwdriver.

PARTS:

I ordered this harness from Ebay for $36.

Some people have complained about the Putco relays. The Putco also does not have a fuse.

Others talk about splicing in better relays, but I'm no electrician. For another $10, I went with this, which is cheaper than splicing in relays to the $25 Putco.

Some have also said the Putco is short. I found the extra length to be helpful while snaking these cables around.

Here are the headlights for $44

These also come with the bulbs, so it's one less thing to have to learn about.

Make sure you order DOT approved, otherwise you might not pass inspection.

The Ebay seller has Euro "E" that are not USA legal, and he omits that little detail in his ad.

STEPS:

1) Disconnect the battery. You can just black negative terminal. Put a sock over it so it doesn't reconnect on accident.

2) Remove the headlight bezels. There are 2 screws on each side.

3) Remove the grille. There are 4 screws.

4) Remove the 4 screws that hold the headlight retainer bezel.

These are rusted and you will need to press hard to break them free.

I used PB blaster for a few days before the weekend.

One of my screws was stripped.

This added at least an hour to this job.

If this happens to you, you'll need to remove the turn signals out of the way before you begin to battle that screw.

First I tried screw extractors.

They are complete garbage and didn't do a thing.

Or, maybe I don't know how to use them.

I tried to use them in my drill, and they did nothing but carve a nice circle into the screw head.

Basically did what a (crappy) drill bit would do.

I then tried a dremel cutting wheel.

I was unable to get it flush enough, so it made no difference, and the screw still held the ring in.

I then tried a drill bit. It also did nothing.

When I did it, it just made a round cavity in the screw head.

And the hacked up screw still held the retainer ring firmly in place.

I think I might need to ask a professional mechanic to show me how to drill out a screw.

Or, next time, I will try an angle grinder and just obliterate the screw head entirely.

So, I gave up and realized that drilling out a screw is beyond my experience & ability level.

Instead, since I had gotten 3 out of 4 screws out, I just bent the retainer ring down to free the headlight.

Eventually, I just got pissed and ripped the retainer ring off the screw.

I tried to get this screw out by just bending it from behind with needlenose, but it was frozen solid.

5) Next, it's time to unplug the old headlights.

The plugs have been fastened for 15 years, so they are really stuck on.

Also, you need to pry apart the clip.

I had to use a screwdriver to gently pry off the clip.

There was no way to do it with bare hands.

6) Now, you need to connect the new harness.

Make sure you snake the cables backwards so you can tuck them away.

I hooked the red power to the fuse box power bolt.

7) Snake the cables to where they need to go.

This will take some time to see how it's routed.

Snake the driver's side across the grill where the original wiring goes.

In the grille, zip tie the long cable to the old cable

Feed each bulb connector into each housing.

Tip: Get under the Jeep to see where to route them.

You will connect the new harness into the old headlight socket.

8) Each new bulb socket has a ground wire.

I connected the passenger ground to the same ground where the negative battery terminal connects to.

I was confused where to ground the driver's side.

Here is what I did, and I don't know if that is correct.

9) Connect the new headlights to the new sockets.

You also need to install the bulb into the headlight.

The thing that you remove can be thrown away.

Don't forget to add the rubber boot before connecting.

11) Test the headlights.

Success!!! And way brighter than before!!

12) Secure the relay housing.

This was another detail no one mentions when they say this is a 15 mins. job.

There was no room to put it anywhere.

The one screw that was available was too high, and the hood would have hit the relays when closed,

I saw a cavity in the fender, but do not know if water comes in there.

Where did you screw yours to?

I had no idea where to put it, so I just tucked it away near the fuse box.

I did not screw it onto anything, but it's not going to move much.

I read that the relays can get wet, and there's a right way to install them.

(Upside down? Right side up? I was unable to understand the right way, and of course, no one ever posts a photo)

So, I just bagged the relays in saran wrap and rubbed banded it tight, and tucked it up near the fuse box.

Hope that works.

13) Reinstall the headlight retainer ring, grille, and bezels.

Last edited by BimmerJeeper; 10-29-2014 at 08:07 PM.

#3

CF Veteran

Nice write up. Was looking into this the other day.

When you encounter screw/fastener issues, Google/Youtube the solution, there are many out there.

Not sure about the safety/melting/fire hazard regarding the wrapped up relays?

Other than that, thanks for all the work on this.

When you encounter screw/fastener issues, Google/Youtube the solution, there are many out there.

Not sure about the safety/melting/fire hazard regarding the wrapped up relays?

Other than that, thanks for all the work on this.

#5

Banned

Thread Starter

Join Date: Oct 2012

Location: USA

Posts: 1,744

Likes: 0

Received 1 Like

on

1 Post

Year: 1998

Model: Cherokee

Engine: 4.0L i6

Nice write up. Was looking into this the other day.

When you encounter screw/fastener issues, Google/Youtube the solution, there are many out there.

Not sure about the safety/melting/fire hazard regarding the wrapped up relays?

Other than that, thanks for all the work on this.

When you encounter screw/fastener issues, Google/Youtube the solution, there are many out there.

Not sure about the safety/melting/fire hazard regarding the wrapped up relays?

Other than that, thanks for all the work on this.

The screw extractors did not work at all.

In the videos, they all use SCREW shaped extractors, not square extractors.

People in the Jeep forum all say the square ones are so great,

but I found them to be totally useless. They didn't even remotely grip the screw.

There was as good as using a wooden dowel!

I was not skilled enough the with dremel to cut the screw head flush enough.

The thin layer that remained was enough to keep holding in retainer ring.

And drilling didn't do anything either. It just made a cavity.

That little headlight screw is basically indestructible!

#7

Herp Derp Jerp

Join Date: Nov 2011

Location: Parham, ON

Posts: 18,251

Likes: 0

Received 12 Likes

on

11 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L OBD-II

Nice writeup. The original headlamp sockets are difficult to remove from the sealed bulbs because they corrode into the pins. The same will happen with your new sockets and the nice new H4 bulbs. You should look into a product like Gardner Bender Ox-Gard or Ideal NOALOX: Stuff is a conductive grease suitable for putting directly on contacts like that. You'll find it in the electrical section at Home Depot, Lowe's, etc. It's used for mating aluminum and copper conductors, and works great at preventing corrosion in an automotive application too. As I said it is conductive, though, so don't make a mess with it. Some on the blades of the H4 bulb is good enough.

For reference, the spiral screw extractors are designed to be set into a hole in the stuck fastener, then turned in the opposite direction. Using them in a drill is just going to make a mess.

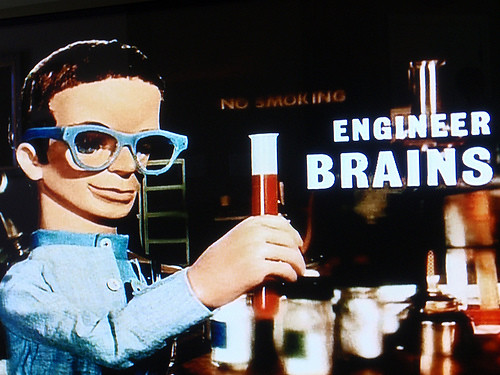

THUNDERBIRDS ARE GO

For reference, the spiral screw extractors are designed to be set into a hole in the stuck fastener, then turned in the opposite direction. Using them in a drill is just going to make a mess.

THUNDERBIRDS ARE GO

Trending Topics

#8

CF Veteran

Join Date: Mar 2013

Location: salem, OR

Posts: 1,023

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1997

Model: Cherokee

Engine: 4.0L

#9

Senior Member

Join Date: Aug 2009

Location: Tulsa,Oklahoma

Posts: 838

Likes: 0

Received 0 Likes

on

0 Posts

Year: 97

Model: Cherokee

Engine: 4.0

Good job man!! And nice to see you bought decent tools (square bit set)...

if you have the ability to complete this task you should easily be able to use that bit set successfully, a "professional" mechanic would not only laugh, but probably take advantage of the situation...

EDIT: maybe use a pair of needle-nose behind the screw holding and bracing it while you use a bit same size as screw, the 'cavity' you made will break it down and or allow the larger bit size to chase afterward...

go for it!!

if you have the ability to complete this task you should easily be able to use that bit set successfully, a "professional" mechanic would not only laugh, but probably take advantage of the situation...

EDIT: maybe use a pair of needle-nose behind the screw holding and bracing it while you use a bit same size as screw, the 'cavity' you made will break it down and or allow the larger bit size to chase afterward...

go for it!!

Last edited by DieselDaze; 11-09-2013 at 07:14 PM.

#10

Banned

Thread Starter

Join Date: Oct 2012

Location: USA

Posts: 1,744

Likes: 0

Received 1 Like

on

1 Post

Year: 1998

Model: Cherokee

Engine: 4.0L i6

Daze,

I am going to buy a set of real screw extractors, and see if I can get them to work with a drill. If that also fails, I will buy a new set of drill bits, and try to just drill the damn screw out and replace with a nut/bolt.

I am going to buy a set of real screw extractors, and see if I can get them to work with a drill. If that also fails, I will buy a new set of drill bits, and try to just drill the damn screw out and replace with a nut/bolt.

#11

Banned

Thread Starter

Join Date: Oct 2012

Location: USA

Posts: 1,744

Likes: 0

Received 1 Like

on

1 Post

Year: 1998

Model: Cherokee

Engine: 4.0L i6

What exactly is the reason for the terribly dim stocks headlights?

1) Did the brightness degrade over time?

Is it the connection prongs oxidize and block voltage?

But, I've had older cars that didn't have such dim headlights.

Were new XJ's a lot brighter, or were they also weak from the start?

2) Are the OEM headlights just a low watt rating?

(What wattage are the OEM lights?)

3) Is the wiring harness known to be faulty? Can't carry a lot of current?

4) Or a inherent electrical design flaw? I am wondering about the design of the original circuit. The advantage of this new relay design is a direct 12-14V feed to the battery, with the headlight switch just acting as a trigger to close the new battery->headlight circuit. But, with the original design, isn't that also, in the end, connected to the battery? Battery->headlight switch->headlights. So what was limiting the OEM circuit from delivering the same 12V-14V to the lights? In the end, both designs have a closed circuit with the battery and headlights, right? In the OEM design, does the headlight switch act as some sort of bottleneck? Was current or voltage being lost somewhere? (If you know this answer, please assume minimal electrical knowledge)

1) Did the brightness degrade over time?

Is it the connection prongs oxidize and block voltage?

But, I've had older cars that didn't have such dim headlights.

Were new XJ's a lot brighter, or were they also weak from the start?

2) Are the OEM headlights just a low watt rating?

(What wattage are the OEM lights?)

3) Is the wiring harness known to be faulty? Can't carry a lot of current?

4) Or a inherent electrical design flaw? I am wondering about the design of the original circuit. The advantage of this new relay design is a direct 12-14V feed to the battery, with the headlight switch just acting as a trigger to close the new battery->headlight circuit. But, with the original design, isn't that also, in the end, connected to the battery? Battery->headlight switch->headlights. So what was limiting the OEM circuit from delivering the same 12V-14V to the lights? In the end, both designs have a closed circuit with the battery and headlights, right? In the OEM design, does the headlight switch act as some sort of bottleneck? Was current or voltage being lost somewhere? (If you know this answer, please assume minimal electrical knowledge)

#13

Senior Member

Join Date: Oct 2011

Location: St. Albert

Posts: 731

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1989

Model: Cherokee

Engine: 4.0L I6

#15

Herp Derp Jerp

Join Date: Nov 2011

Location: Parham, ON

Posts: 18,251

Likes: 0

Received 12 Likes

on

11 Posts

Year: 1999

Model: Cherokee

Engine: 4.0L OBD-II

What exactly is the reason for the terribly dim stocks headlights?

1) Did the brightness degrade over time?

Is it the connection prongs oxidize and block voltage?

But, I've had older cars that didn't have such dim headlights.

Were new XJ's a lot brighter, or were they also weak from the start?

2) Are the OEM headlights just a low watt rating?

(What wattage are the OEM lights?)

3) Is the wiring harness known to be faulty? Can't carry a lot of current?

4) Or a inherent electrical design flaw? I am wondering about the design of the original circuit. The advantage of this new relay design is a direct 12-14V feed to the battery, with the headlight switch just acting as a trigger to close the new battery->headlight circuit. But, with the original design, isn't that also, in the end, connected to the battery? Battery->headlight switch->headlights. So what was limiting the OEM circuit from delivering the same 12V-14V to the lights? In the end, both designs have a closed circuit with the battery and headlights, right? In the OEM design, does the headlight switch act as some sort of bottleneck? Was current or voltage being lost somewhere? (If you know this answer, please assume minimal electrical knowledge)

1) Did the brightness degrade over time?

Is it the connection prongs oxidize and block voltage?

But, I've had older cars that didn't have such dim headlights.

Were new XJ's a lot brighter, or were they also weak from the start?

2) Are the OEM headlights just a low watt rating?

(What wattage are the OEM lights?)

3) Is the wiring harness known to be faulty? Can't carry a lot of current?

4) Or a inherent electrical design flaw? I am wondering about the design of the original circuit. The advantage of this new relay design is a direct 12-14V feed to the battery, with the headlight switch just acting as a trigger to close the new battery->headlight circuit. But, with the original design, isn't that also, in the end, connected to the battery? Battery->headlight switch->headlights. So what was limiting the OEM circuit from delivering the same 12V-14V to the lights? In the end, both designs have a closed circuit with the battery and headlights, right? In the OEM design, does the headlight switch act as some sort of bottleneck? Was current or voltage being lost somewhere? (If you know this answer, please assume minimal electrical knowledge)

The stock headlight wiring is of an incredibly short-sighted design made for ease of installation and low cost. The power flows from the battery, to the junction block, to the headlight switch, to the lamps over measly 18 AWG wire. The tiny wire and long length means that there's an unavoidable drop in voltage: about 5% for stock low beams, up to 15% for high beams or bright aftermarket lights. Just from how tiny the wire is. Now take 13-25 years of rain and salt exposure that adds corrosion, which increases resistance and drives up overall current; and 13-25 years of vibration, which inevitably results in a few broken strands in the wire, increasing resistance and driving up current. It's not uncommon for a voltage drop of 20% or more at the headlight sockets of an aged XJ. Aside from being incredibly dim, the power requirements go way up as resistance increases. The next weakest point in the system is the headlight switch: It, like most switches, is built with smaller conductors and favors a compact size over heat performance. With 40A or more going through this thing from all lighting on the vehicle (can you say "single point of failure") it's no surprise that if they don't outright melt, heat cycling causes failure.

A proper harness moves the biggest load off of the switch to a relay-driven circuit on heavy gauge wire. A short run directly from the battery is ideal. The stock wiring is then used only as a means of controlling the relays, which is about a 500 mA load, compared to the previous 10-20. The lamps get way more current available with almost no loss, and a substantial load is removed from ancient wiring and a critical switch.

A proper harness moves the biggest load off of the switch to a relay-driven circuit on heavy gauge wire. A short run directly from the battery is ideal. The stock wiring is then used only as a means of controlling the relays, which is about a 500 mA load, compared to the previous 10-20. The lamps get way more current available with almost no loss, and a substantial load is removed from ancient wiring and a critical switch.