Last edit by: IB Advertising

See related guides and technical advice from our community experts:

Browse all: Electrical Guides

- Jeep Cherokee 1984-2001: How to Replace Crankshaft Position Sensor

Step by step instructions for do-it-yourself repairs.

Browse all: Electrical Guides

Awesome Crankshaft Position Sensor how-to

#16

Junior Member

Join Date: Jul 2011

Location: Canyon Lake, TX

Posts: 33

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1996

Model: Cherokee

Engine: 4.0 HO

I did mine yesterday.

I don't have the u-joint or long extensions, so I dropped the trans crossmember about 2" on the driver side. I'd have dropped it farther, but I only had the factory bottle jack.

I was able to get my left hand up to the sensor to guide the socket and catch the bolts. I used two 3" extensions on my 3/8" ratchet and took off the bracket that holds the end of the shifter cable housing to get my right hand in to operate the ratchet. This also allowed me to reinstall the bolts by hand and go hand tight before going to the ratchet.

Started up first try

Not bad for a fiftysumpthin' woman that hasn't done car work for about twenty years. Proves that you never forget some things, unless Alzheimer's does it for you.

I don't have the u-joint or long extensions, so I dropped the trans crossmember about 2" on the driver side. I'd have dropped it farther, but I only had the factory bottle jack.

I was able to get my left hand up to the sensor to guide the socket and catch the bolts. I used two 3" extensions on my 3/8" ratchet and took off the bracket that holds the end of the shifter cable housing to get my right hand in to operate the ratchet. This also allowed me to reinstall the bolts by hand and go hand tight before going to the ratchet.

Started up first try

Not bad for a fiftysumpthin' woman that hasn't done car work for about twenty years. Proves that you never forget some things, unless Alzheimer's does it for you.

#17

CF Veteran

Join Date: Sep 2011

Location: Riviera, Texas

Posts: 4,172

Likes: 0

Received 4 Likes

on

4 Posts

Year: 1998 Sport

Model: Cherokee

Engine: 4.0

I did mine about a year ago. Yes it started out as a real easy job but ended being a $450 job. The problem I had was first the top bolt snapped off then the second bolt snapped off too. I ended up having to pull it to a local shop for them to pull the trans and get the broken bolts out. The one good thing I that I did buy a cheap *** cps from ebay and only payed $13 with shipping. But from what I have heard. I am one of the few lucky people that it actually work out for. If or should I say when I have to change it out. I will be getting it from the dealer. It's not worth the risk to cheap out on this part.

Last edited by RTorrez1; 05-11-2012 at 09:49 AM.

#18

Seasoned Member

Join Date: Jan 2009

Location: Middle Tennessee

Posts: 454

Likes: 0

Received 0 Likes

on

0 Posts

Year: 2001

Model: Cherokee

Engine: 4.0L I6

I did mine yesterday.

I don't have the u-joint or long extensions, so I dropped the trans crossmember about 2" on the driver side. I'd have dropped it farther, but I only had the factory bottle jack.

I was able to get my left hand up to the sensor to guide the socket and catch the bolts. I used two 3" extensions on my 3/8" ratchet and took off the bracket that holds the end of the shifter cable housing to get my right hand in to operate the ratchet. This also allowed me to reinstall the bolts by hand and go hand tight before going to the ratchet.

Started up first try

Not bad for a fiftysumpthin' woman that hasn't done car work for about twenty years. Proves that you never forget some things, unless Alzheimer's does it for you.

I don't have the u-joint or long extensions, so I dropped the trans crossmember about 2" on the driver side. I'd have dropped it farther, but I only had the factory bottle jack.

I was able to get my left hand up to the sensor to guide the socket and catch the bolts. I used two 3" extensions on my 3/8" ratchet and took off the bracket that holds the end of the shifter cable housing to get my right hand in to operate the ratchet. This also allowed me to reinstall the bolts by hand and go hand tight before going to the ratchet.

Started up first try

Not bad for a fiftysumpthin' woman that hasn't done car work for about twenty years. Proves that you never forget some things, unless Alzheimer's does it for you.

#19

Seasoned Member

Join Date: Feb 2011

Location: NJ/NY

Posts: 276

Likes: 0

Received 6 Likes

on

1 Post

Year: 2001

Model: Cherokee

Engine: I6

I did mine on the side of the highway few months ago in the pouring rain..took 20mins but overall it was 3 hours having to wait for my wife to get out of work, for her to go to the auto parts store and get the sensor and pick up my 3/8 metric socket set. couldn't have done it without the wifey! Hardest part was trying to seat the sensor in with such little room for my hand and working the bolt.

#20

Junior Member

Join Date: Nov 2010

Location: Carson City, NV

Posts: 87

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1989

Model: Cherokee

Engine: 4.0

Any of you guys that have done this remember what size socket to use? Gotta do it later this week and it wouldn't hurt knowing what it is.

#21

CF Veteran

Join Date: Mar 2010

Location: Jacksonville, FL

Posts: 6,685

Likes: 0

Received 5 Likes

on

5 Posts

Year: 92

Model: Cherokee

Engine: 4.0

Originally Posted by jeepxj24

Any of you guys that have done this remember what size socket to use? Gotta do it later this week and it wouldn't hurt knowing what it is.

#23

Senior Member

Join Date: Jan 2011

Location: Joliet, Il

Posts: 730

Likes: 0

Received 2 Likes

on

2 Posts

Year: 1996

Model: Cherokee

Engine: HO4.0 I6

I did mine yesterday.

I don't have the u-joint or long extensions, so I dropped the trans crossmember about 2" on the driver side. I'd have dropped it farther, but I only had the factory bottle jack.

I was able to get my left hand up to the sensor to guide the socket and catch the bolts. I used two 3" extensions on my 3/8" ratchet and took off the bracket that holds the end of the shifter cable housing to get my right hand in to operate the ratchet. This also allowed me to reinstall the bolts by hand and go hand tight before going to the ratchet.

Started up first try

Not bad for a fiftysumpthin' woman that hasn't done car work for about twenty years. Proves that you never forget some things, unless Alzheimer's does it for you.

I don't have the u-joint or long extensions, so I dropped the trans crossmember about 2" on the driver side. I'd have dropped it farther, but I only had the factory bottle jack.

I was able to get my left hand up to the sensor to guide the socket and catch the bolts. I used two 3" extensions on my 3/8" ratchet and took off the bracket that holds the end of the shifter cable housing to get my right hand in to operate the ratchet. This also allowed me to reinstall the bolts by hand and go hand tight before going to the ratchet.

Started up first try

Not bad for a fiftysumpthin' woman that hasn't done car work for about twenty years. Proves that you never forget some things, unless Alzheimer's does it for you.

I have tried starting with it in half and then connecting it but I couldn't get to it. I am debating if I should start moving stuff around to make it easier. Or if I should try one more time. I have no idea how all of you guys do this stuff in minutes...

#24

Senior Member

Join Date: Jun 2009

Location: West Texas

Posts: 553

Likes: 0

Received 1 Like

on

1 Post

Year: 1991

Model: Cherokee

Engine: 4.0 L

USE gum in the socket! works great!

USE gum in the socket! works great!I usually put thick blanket over top of motor, and using a 11mm "ratchet" box wrench and some contorshonist trickery I can at least get the bolts out,

however, the extension and universal(spring loaded so it stays at the correct angle) 3/8" drive works pretty good, but yeah he is right on with that!

cpnwrench

#25

I used 3 6" extensions with a universal on the end of those and then the 11mm socket. This allowed my to access the lower bolt pretty easily. For the upper bolt, I laid thick cardboard over the engine for my comfort, layed on that and then reached behind the block with an 11mm combination wrench - the type with the box end offset a bit. It's tight back there and using the wrench is slow, but I've done it twice this week and it hasn't taken me more than 30 minutes either time.

Who knows, maybe one day my Jeep will even run again....

Who knows, maybe one day my Jeep will even run again....

#27

No magnet. If you have the hood open and enough light you can view the lower bolt progress pretty well. Even if it drops it should drop to the floor. The upper bolt is the one you need to worry about dropping into the bell housing - which wouldn't be the end of the world either. There's a removable plate at the lower edge of the housing for inspection. I'd bet you could run a magnet into there if you drop the bolt.

#28

Newbie

Join Date: Aug 2018

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

Year: 1999

Model: Cherokee (XJ)

Engine: 2.5L

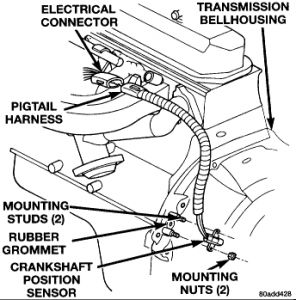

Replacing the CPS and I was not lucky enough to have mounting bolts to remove. Instead I have mounting studs and 2 nuts and after removing the nuts the studs are still blocking the CPS from sliding out of its housing. Any tips to remove the studs?

#30

CF Veteran

Join Date: Dec 2015

Location: PA

Posts: 3,038

Likes: 0

Received 333 Likes

on

277 Posts

Year: 1997

Model: Cherokee

Engine: 4.0L